Gas logging total hydrocarbon correction method

A correction method and gas measurement technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of limited model accuracy, unstable application effect, excessive human factors, etc., and achieve the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As the best implementation mode of the present invention, it discloses a kind of method for correcting all hydrocarbons in gas detection, and its steps are:

[0039] a. Carry out correlation analysis between the total hydrocarbon value shown by the gas test in the regional oil test section and the corresponding test data, and establish the correlation formula between the two.

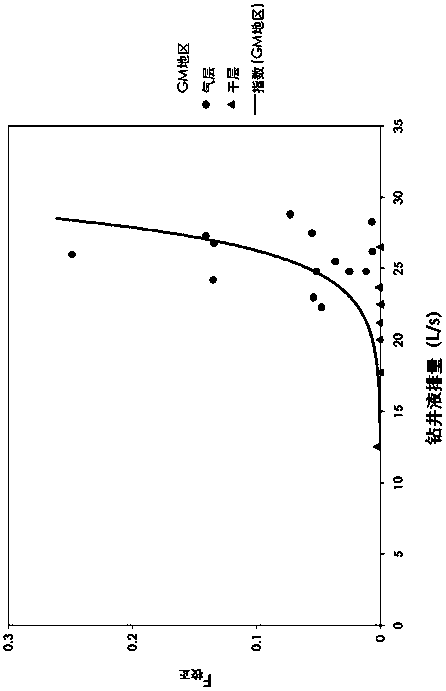

[0040] b. Based on the relevant formulas of the above two, combined with the impact model of drill bit size, drilling fluid displacement and drilling time on gas measurement full hydrocarbons and the gas measurement full hydrocarbon correction target, the gas measurement full hydrocarbon correction model is derived;

[0041] c. Substituting the regional data into the full hydrocarbon correction model for gas logging to perform correlation analysis on the correction value obtained with the corresponding drill bit size, drilling fluid displacement and drilling time, and obtain the gas logging correc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com