Small solid rocket engine jet pipe blocking cover

A technology for engine nozzles and solid rockets, which can be used in rocket motor devices, machines/engines, mechanical equipment, etc., and can solve problems such as debonding of bonding parts, narrow application range, and unstable bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

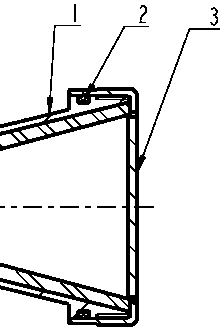

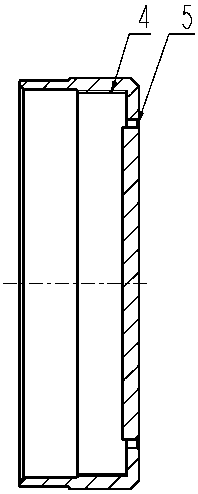

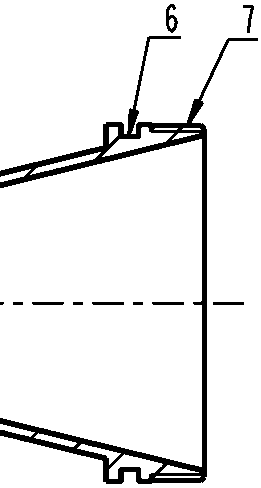

[0014] Such as figure 1 and 2 Shown, a kind of small-sized solid rocket motor nozzle capping, described capping 3 is provided with capping connecting thread 4, and nozzle capping is connected with nozzle shell side wall by capping connecting thread 4, described The nozzle cap is provided with a shear groove, and the shear groove is arranged on the contact surface between the plug and the nozzle. The connecting thread 4 of the plug is connected with the side wall of the nozzle through the sealing ring 2 . During specific implementation, the dimensions of the shear groove 5 and the connecting thread 4, 7 are calculated according to the opening pressure requirement of the nozzle plug. The side seal compression of sealing ring 2 is selected as 15%. When the nozzle cap of the present invention is used, the seal ring 2 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com