Low-resistance extraction strong backflow planar valve compound pump

A composite pump and plane valve technology, applied in the components, pumps, pump elements, etc. of the pumping device for elastic fluid, can solve the problem of losing a large number of injection channels and a small amount of injection channels to prevent, reduce, and block the backflow. and other problems to achieve the effect of reducing wear, reducing manufacturing costs and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

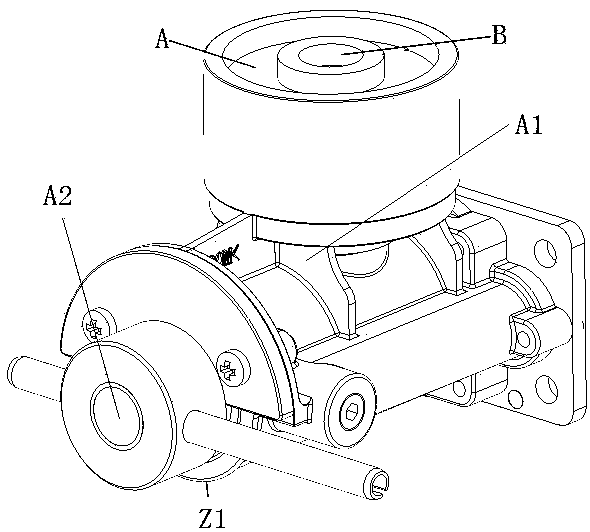

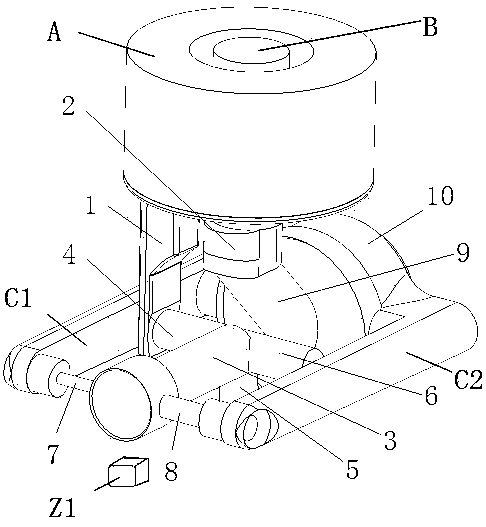

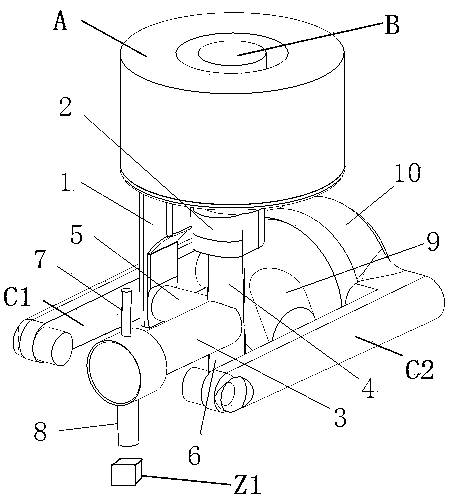

[0054] like figure 1 and Figure 38 As shown, the low-resistance pumping strong backflow planar valve compound pump includes large and small pumps with piston structure. The large and small pumps with piston structure are to set a small pump cavity at the bottom of the outlet in the large pump cavity. The end face of the large piston protrudes from the small piston, the small piston and the small pump cavity form a small pump, and the large pump and small pump form a compound pump; and the control valve for controlling the circulation of the large and small compound pumps, the control valve includes a valve body and a valve core, and the valve body A spool cavity for the rotating spool is provided, and the spool is placed in the spool cavity; a channel A is provided on the valve body, and one end of the channel A is connected to the large pump;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com