Combination pump valve with large pump front end for powerful backflow and low resistance

A composite pump and spool technology, applied to pumps, pump devices, pump components, etc., can solve problems such as clogging, loss of a large number of injection channels, and anti-blocking and reduction of backflow of a small amount of injection channels, so as to reduce manufacturing costs, Effect of reducing wear and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

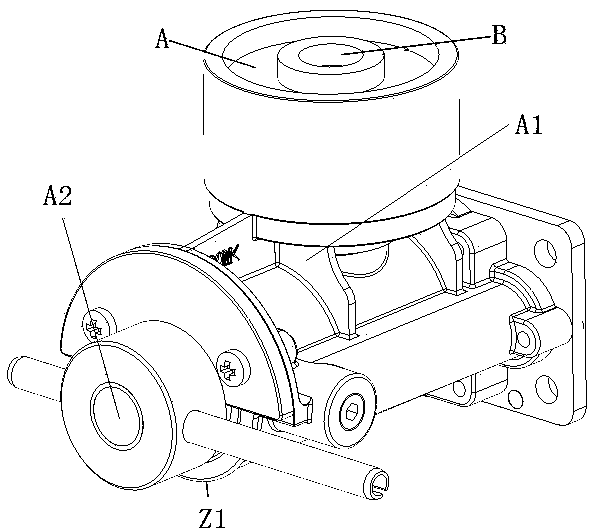

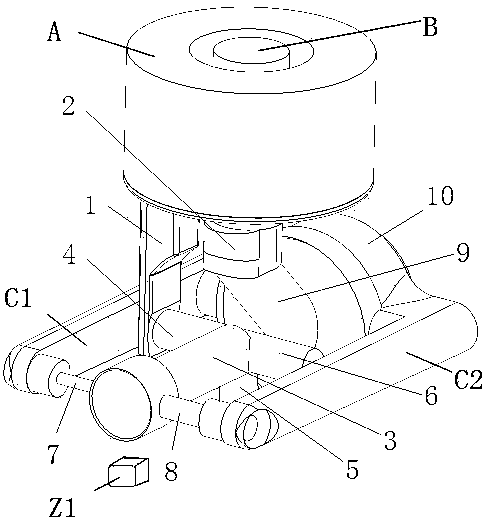

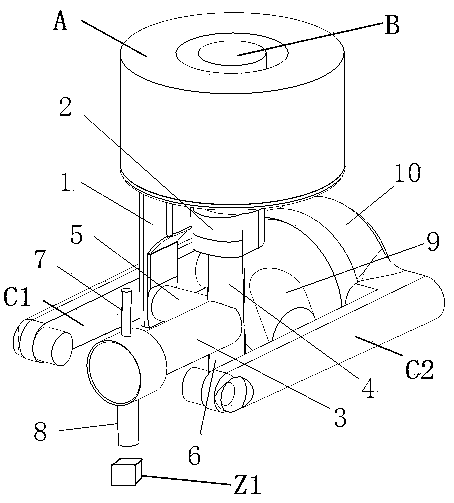

[0052] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

[0053] Such as Figure 22-Figure 25 As shown, the strong backflow low resistance compound pump valve at the front end of the large pump, the valve body is provided with a large pump inlet and outlet 68, a small pump inlet and outlet 69 and a return port 70, and the axial channel 71 of the valve core is provided with a first radial channel 72. The second radial passage 73, the third radial passage 74 and the fourth radial passage 75. One end of the axial passage 71 of the spool is also provided with a first injection passage 76 and a second injection passage 77. The diameter of an injection channel 76 is greater than the diameter of the second injection channel 77, and the other end of the valve core is also provided with a first inclined channel 78 and a second inclined channel 79, one end of the first inclined channel 78 and the second inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com