Surface temperature over-standard detection coating layer of lithium ion battery

A lithium-ion battery, surface temperature technology, applied in the field of lithium-ion batteries, can solve problems affecting battery use, temperature rise, complex and cumbersome devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

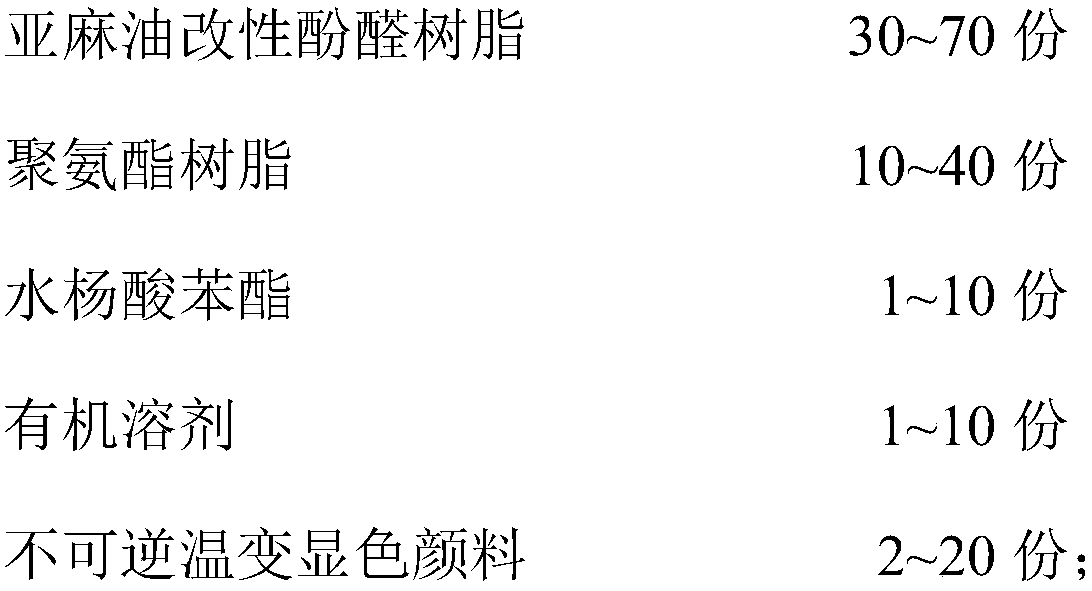

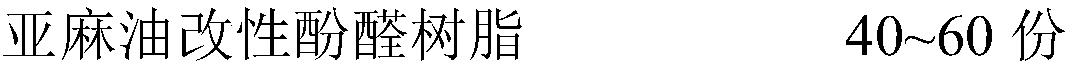

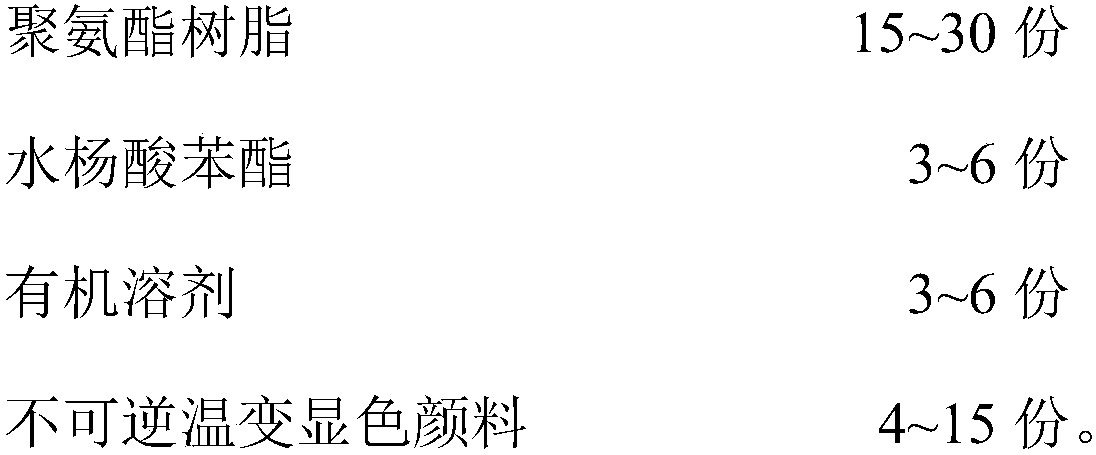

[0029] This embodiment provides a lithium-ion battery surface temperature exceeding standard detection coating, which is arranged on the surface of the battery case, and it includes the following components by mass: 50 parts of linseed oil modified phenolic resin, 25 parts of polyurethane resin, benzene salicylate 5 parts of ester, 5 parts of organic solvent, and 10 parts of irreversible temperature-changing color-developing pigment; wherein, the color-changing temperature of the irreversible temperature-changing color-developing pigment is 65°C. Organic solvents include acetone, toluene and butyl ether in a mass ratio of 5:4:7. The density of polyurethane resin is 1.35g / cm 3 . The viscosity of the polyurethane resin is 1200mPa.s. The irreversible temperature-changing color-developing pigment is an irreversible color-changing red pigment.

Embodiment 2

[0031] Different from Example 1, the lithium-ion battery surface temperature exceeding standard detection coating in this example includes the following components by mass: 45 parts of linseed oil modified phenolic resin, 30 parts of polyurethane resin, 4 parts of phenyl salicylate, 6 parts of organic solvent, 8 parts of irreversible temperature-changing color pigment.

[0032] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0034] Different from Example 1, the lithium-ion battery surface temperature exceeding standard detection coating in this example includes the following components by mass: 55 parts of linseed oil modified phenolic resin, 25 parts of polyurethane resin, 6 parts of phenyl salicylate, 6 parts of organic solvent, 12 parts of irreversible temperature-changing color pigment.

[0035] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com