Bi-directional micro-displacement large-scale precise piezoelectric stick-slip linear motor and driving method thereof

A linear motor, micro-displacement technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of small load output, poor motion stability, complex structure, etc. , to achieve the effect of reducing the displacement return rate, strong load capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

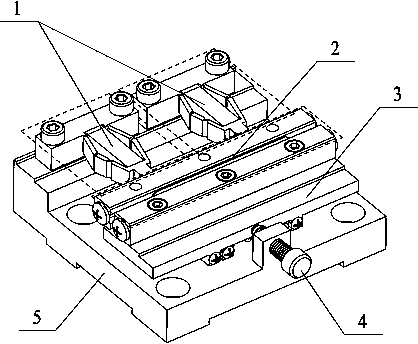

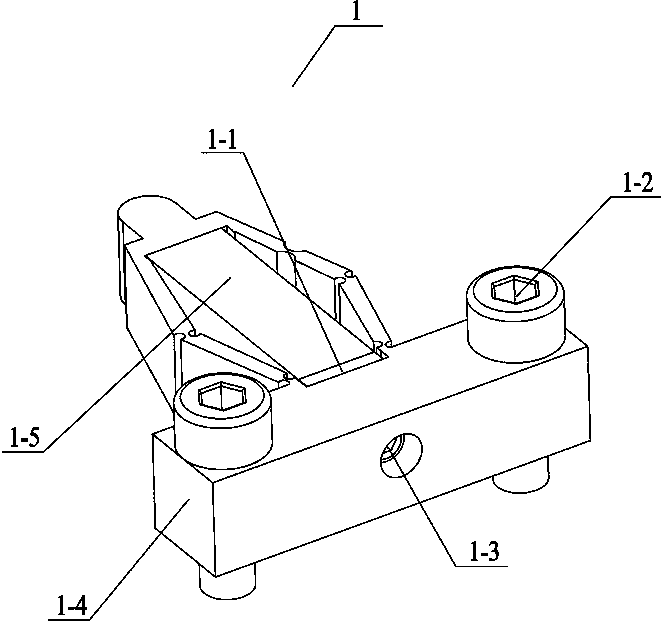

[0030] Specific implementation mode one: combine Figure 1~Figure 9 Describe this embodiment. This embodiment provides a specific implementation of a bidirectional micro-displacement amplified precision piezoelectric stick-slip linear motor. The specific implementation of the bidirectional micro-displacement amplified precision piezoelectric stick-slip linear motor is described as follows:

[0031] The bidirectional micro-displacement amplified precision piezoelectric stick-slip linear motor is composed of an asymmetric drive assembly 1 , a guide rail assembly 2 , a slide table 3 , a preloader 4 and a fixed table 5 .

[0032] The asymmetric drive assembly 1 includes a square washer 1-1, a hinge fixing bolt 1-2, a pre-tightening screw 1-3, an asymmetric diamond-shaped amplifying mechanism 1-4 and a piezoelectric stack 1-5. The square washer 1-1 and the pre-tightening screw 1-3 fix the piezoelectric stack 1-5 in the asymmetric diamond-shaped amplification mechanism 1-4. The sq...

specific Embodiment approach 2

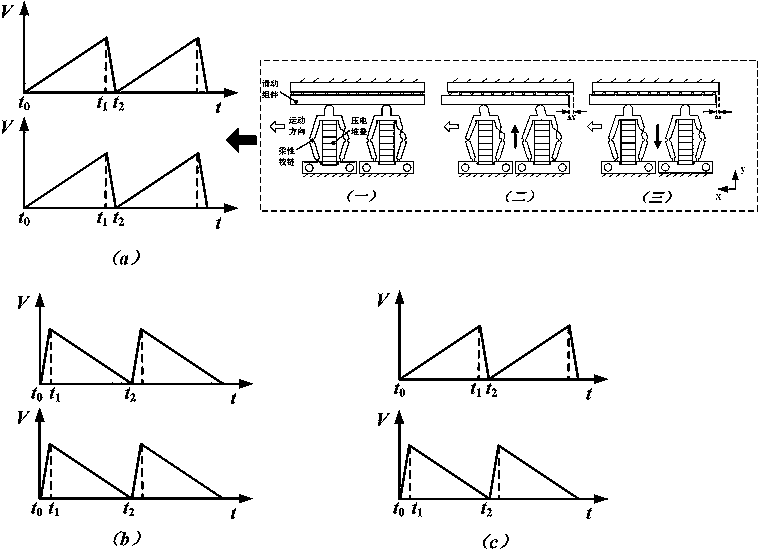

[0037] Specific implementation mode two: combination Figure 10~11 Describe this embodiment. This embodiment proposes a specific implementation of a two-way micro-displacement amplified precision piezoelectric stick-slip linear motor driving method I. The two-way micro-displacement amplified precision piezoelectric stick-slip linear motor drive method Ⅰ is expressed as follows:

[0038] The driving method of the two-way micro-displacement amplification precision piezoelectric stick-slip linear motor can be divided into output enhancement type and motion emergency stop type. 1-4, so that the asymmetric drive assembly 1 is unevenly distributed along the axial direction to generate lateral displacement, adjust the positive pressure of the contact between the asymmetric drive assembly 1 and the guide rail assembly 2, and then regulate the asymmetric drive assembly 1 At the same time, under the excitation of different combinations of asymmetric electrical signals, various driving ...

specific Embodiment approach 3

[0062] Specific implementation mode three: combination Figure 10 , 12 , 13 This embodiment is described. This embodiment proposes a specific implementation of the two-way micro-displacement amplified precision piezoelectric stick-slip linear motor driving method II with an asymmetric drive assembly 1 installed back to back. The two-way micro-displacement amplified precision piezoelectric stick-slip linear motor drive method II with drive components installed back to back is expressed as follows:

[0063] Asymmetric drive components 1. Two-way micro-displacement amplified precision piezoelectric stick-slip linear motors, which are installed back-to-back. The displacement amplified precision piezoelectric stick-slip linear motor adopts asymmetric diamond-shaped amplifying mechanism 1-4, which makes the asymmetric drive assembly 1 have uneven distribution of axial stiffness and produces lateral displacement. Adjust the asymmetric drive assembly 1 and the guide rail The positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com