Embedded aluminum foil foam

An aluminum foil foam, embedded technology, applied in electrical components, magnetic field/electric field shielding and other directions, can solve the problems of poor shielding effect, easy to open glue and loose, easy to loosen aluminum foil, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

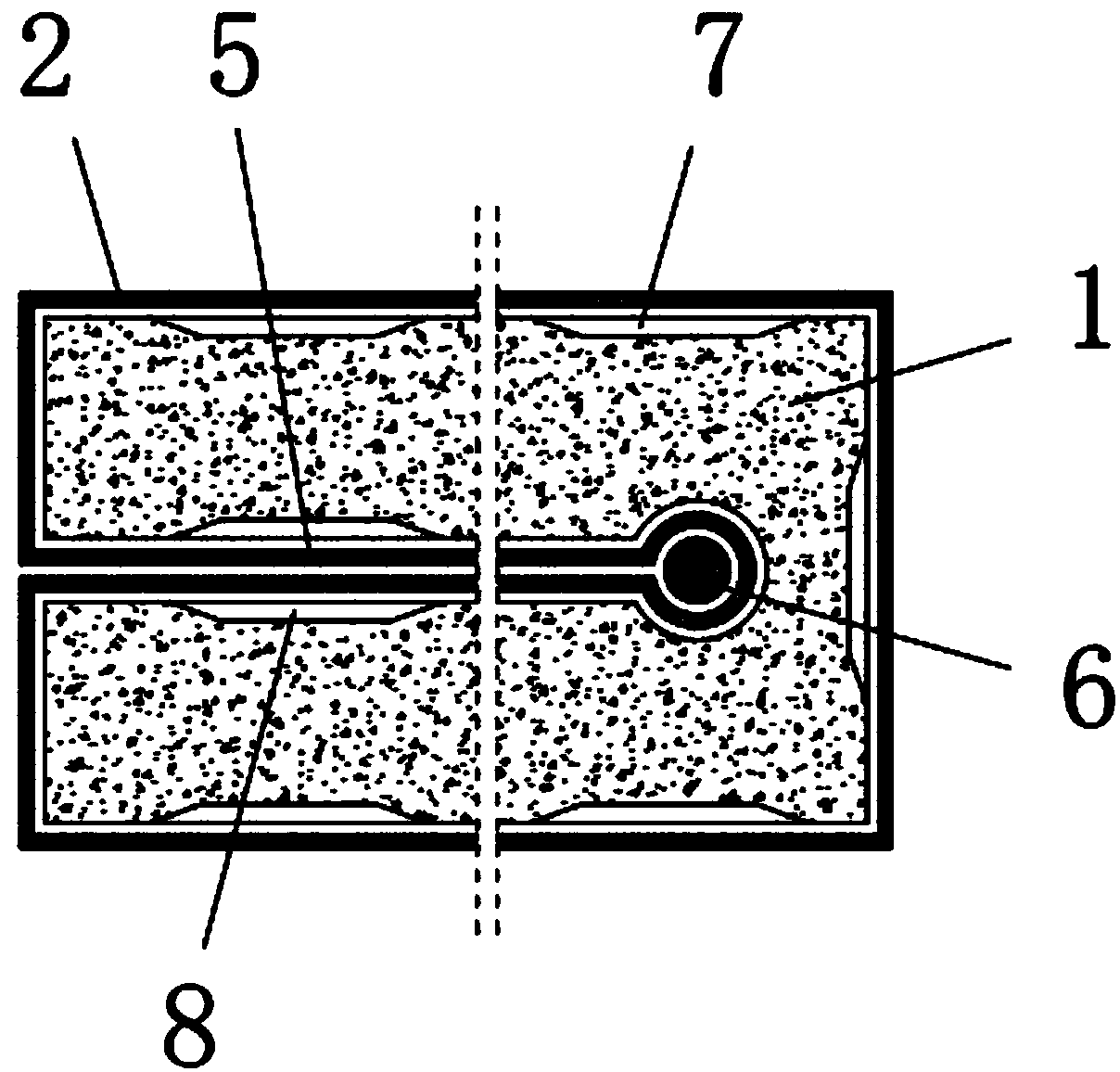

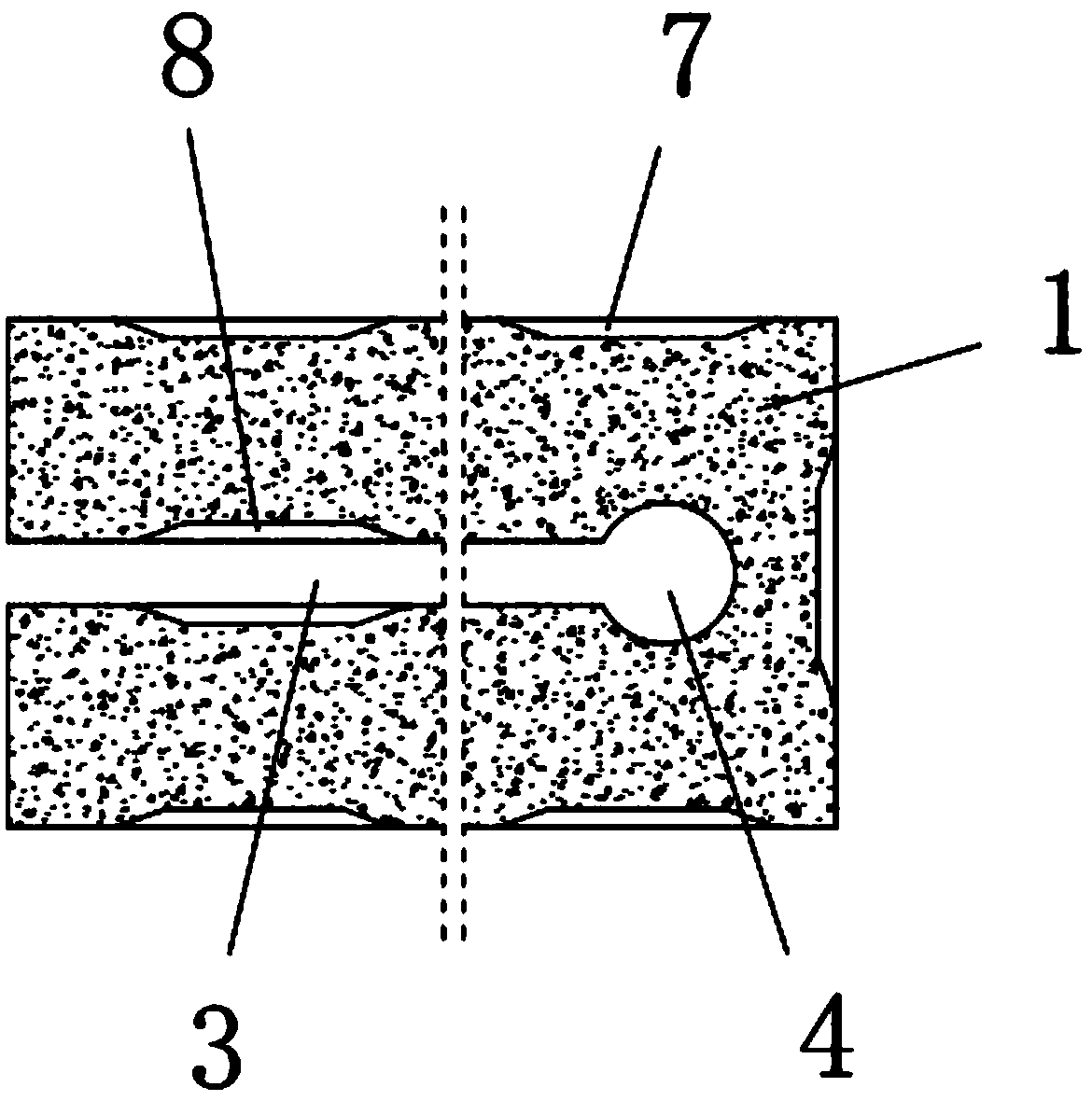

[0017] as attached Figure 1-2 As shown, an embedded aluminum foil foam according to the present invention includes a foam body 1 and an aluminum foil covering layer 2, and the aluminum foil covering layer 2 is wrapped on the outside of the foam body 1; the foam body 1 An embedding groove 3 is provided, and the embedding groove 3 includes an opening end located on one side of the foam body 1 and a tightening end 4 located deep in the foam body 1; the aluminum foil cladding layer 2 also includes an embedded part 5, which is embedded The part 5 extends into the tensioning end 4 through the opening end of the embedding groove 3, and the end of the embedded part 5 cooperates with the tensioning end 4 through the filling part 6. The filling part 6 can be a foam stick, and the foam stick can be embedded by processing Groove 3 is obtained from scraps cut during processing to save material, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap