Belt wheel, winding type transmission mechanism and method for connecting rim and main body of belt wheel

A technology of transmission mechanism and pulley, which is applied to transmission devices, elements with teeth, belts/chains/gears, etc., can solve the problem of high installation cost, achieve economical manufacturing, high safety, and simplify installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

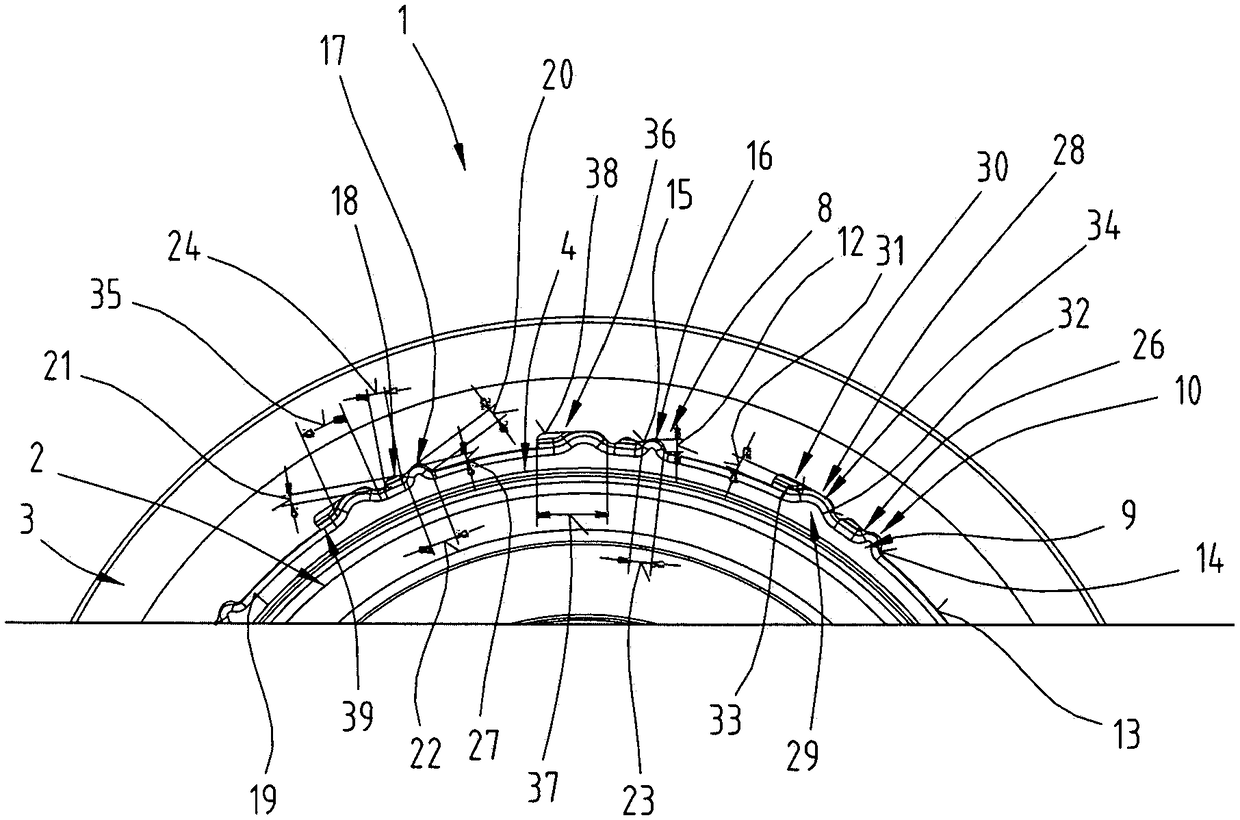

[0035] At the outset, it should be pointed out that the same components have the same reference signs or the same component designations in different embodiments, and that the disclosure contained in the entire description can reasonably be transferred to the same components with the same reference signs or the same component designations superior. Likewise, positional expressions such as top, bottom, side etc. used in the description relate to the current description and the illustrated figures and can be transferred to the new position as appropriate in the event of a position change.

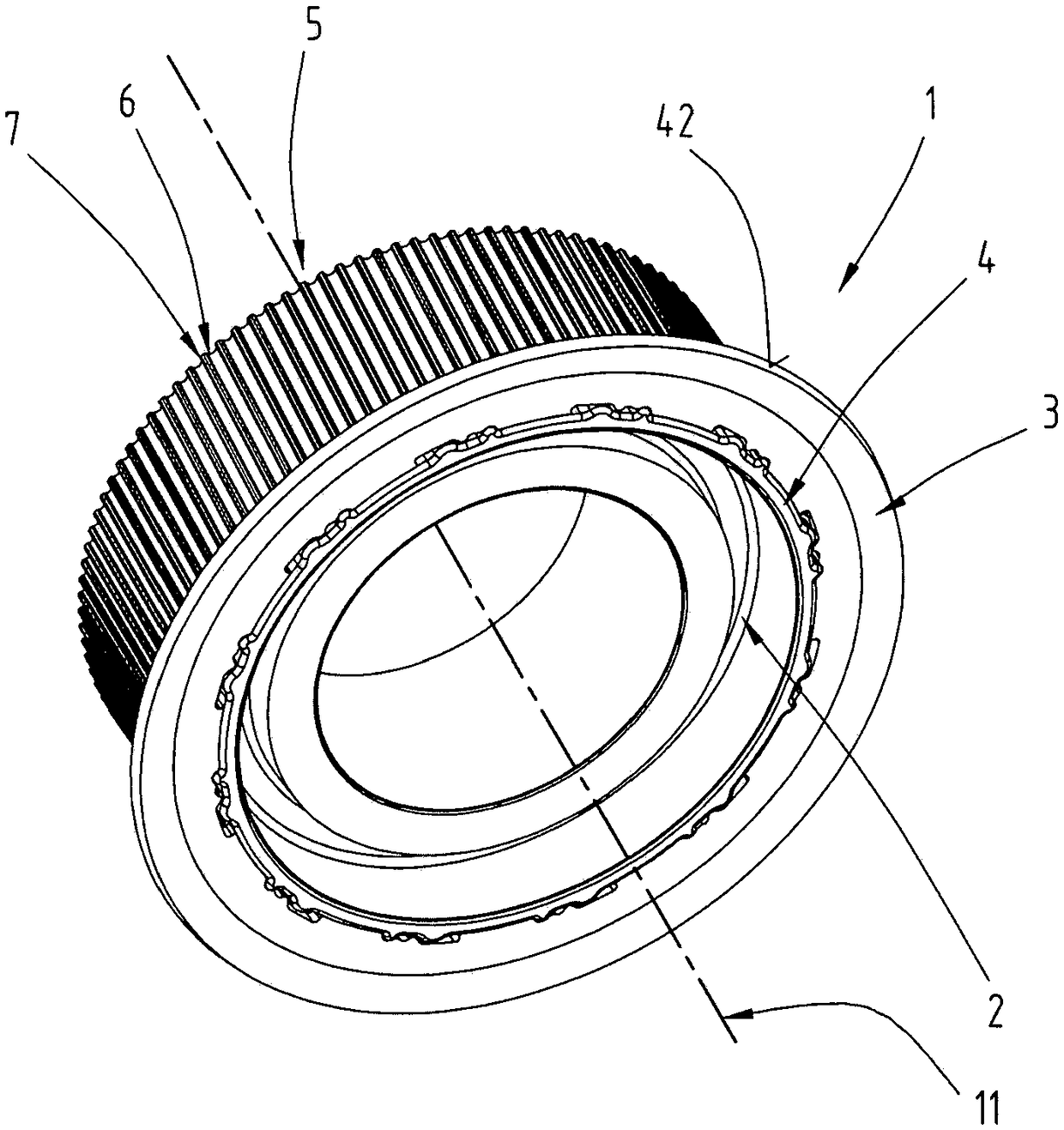

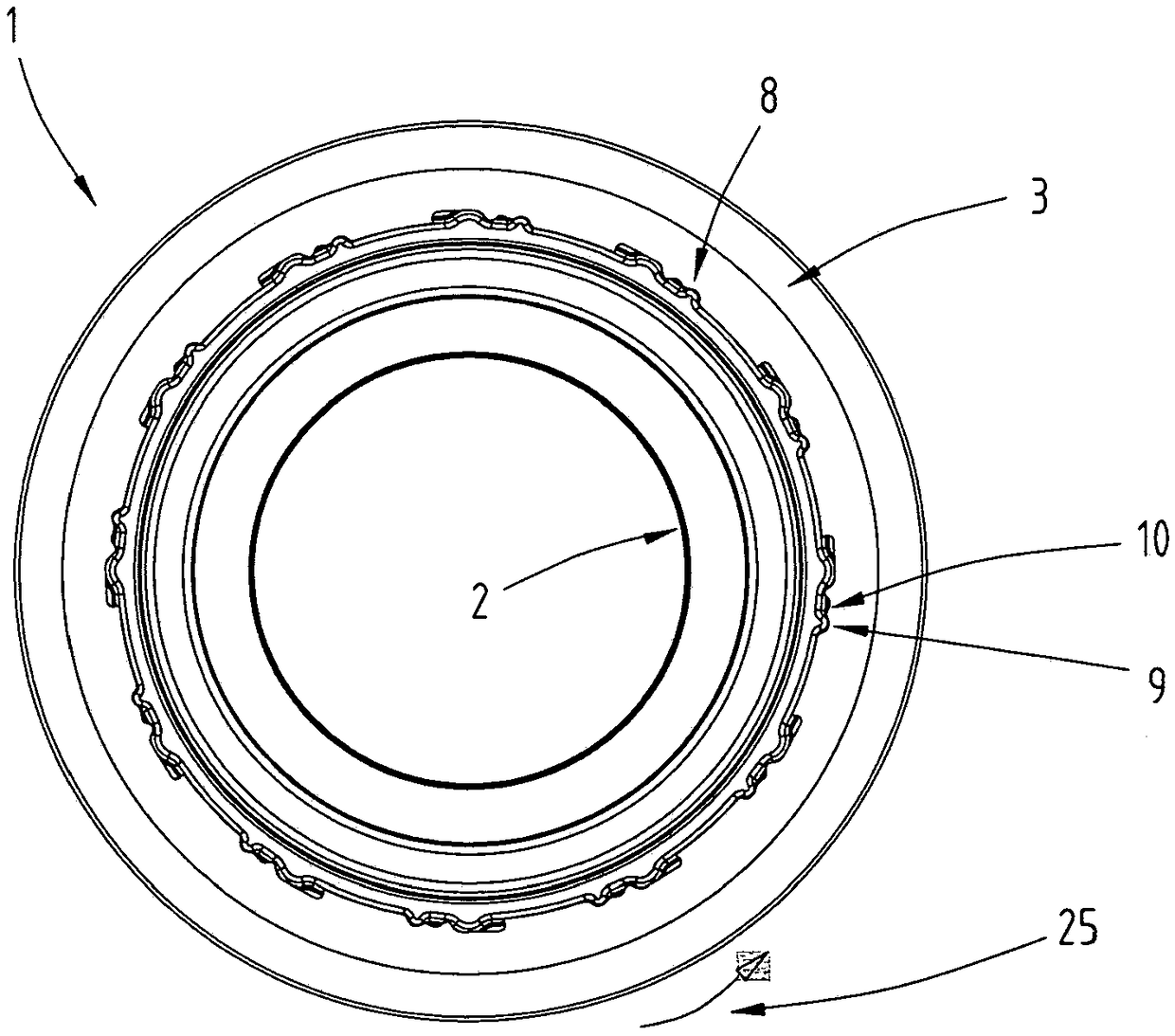

[0036] figure 1 The pulley 1 in the form of a toothed pulley is shown in oblique view. This toothed pulley 1 comprises a base body 2 and a rim 3 (stop disk element), which in this embodiment is designed as a rim disk. The rim 3 is arranged laterally on the end face of the basic body and on the hub 4 of the basic body 2 .

[0037]The base body 2 has toothing 5 on its outer circumference. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com