Environmentally-friendly dipping molds with extended life and method of manufacturing thereof

A mold and life-span technology, applied in the direction of coating, etc., can solve the problems such as dipping mold pollution, and achieve the effect of manufacturing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

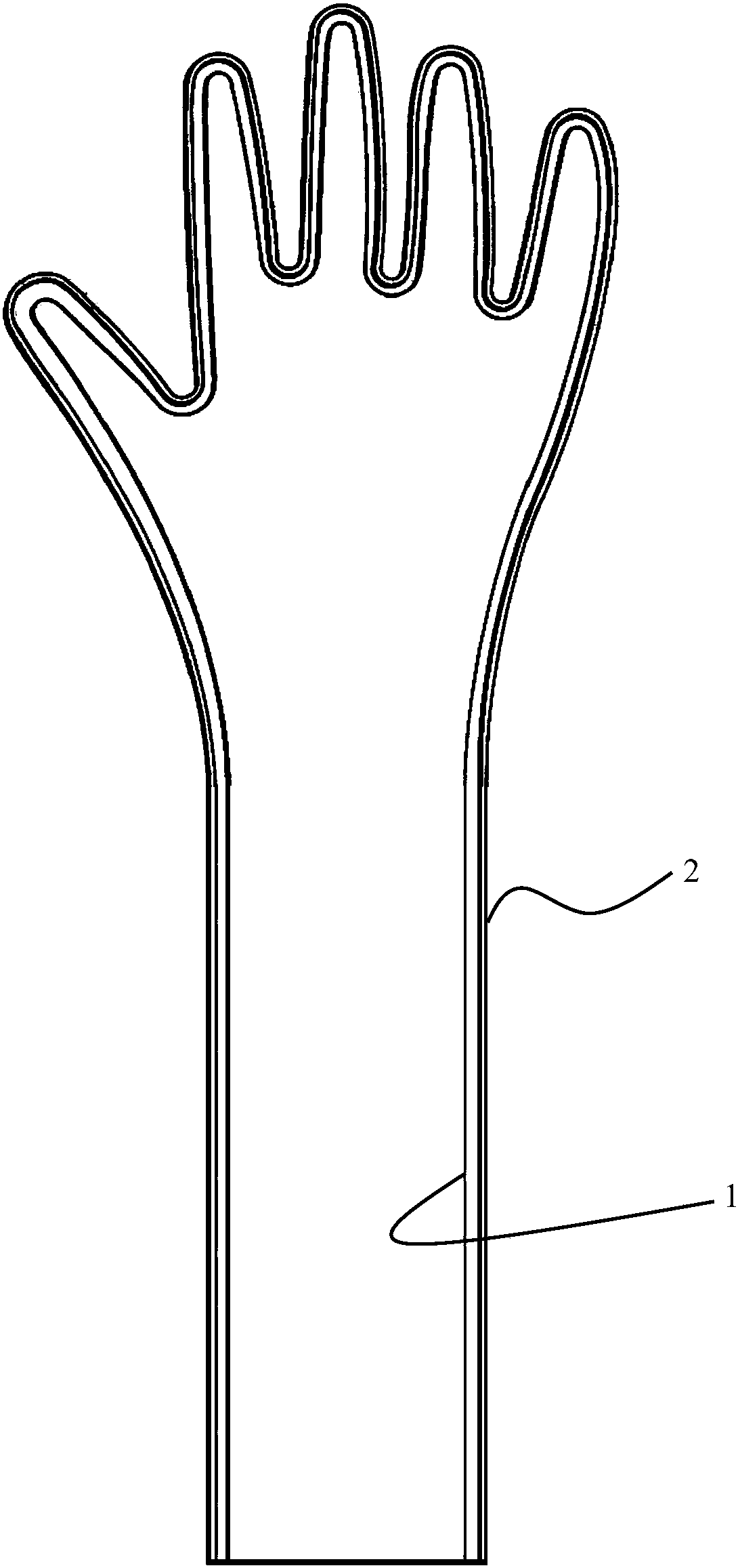

[0028] Referring to the accompanying drawings, the dipping mold with extended service life of the present invention comprises a mold core (1) encased in an outer coating (2) made of a durable material. The mold core (1) may be constructed of ceramic, aluminum or thermoplastic or any other material and the outer coating may comprise any one or combination of the following materials: including Nylon 11 TM Nylon inside TM , polyethylene, polypropylene, PVDF, PEEK, and fluoropolymers, or the exterior coating can be made of epoxy and the coating can be textured.

[0029] The invention also provides a method for manufacturing an impregnated mold having an extended life, the method comprising surrounding a mold core (1) with an outer coating (2) consisting of a durable material.

[0030]Typically, the methods involve multiple steps to achieve optimal results. Taking the manufacture of elastic gloves such as examination gloves, surgical gloves or industrial gloves as an example, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com