Stamping die wire connector

A technology for stamping dies and connectors, which is applied in the direction of connection, conductive connection, clamping/spring connection, etc. It can solve the problems of affecting wiring efficiency, affecting the service life of stamping dies, and material waste, so as to avoid position deviation and ensure firmness The effect of clamping and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

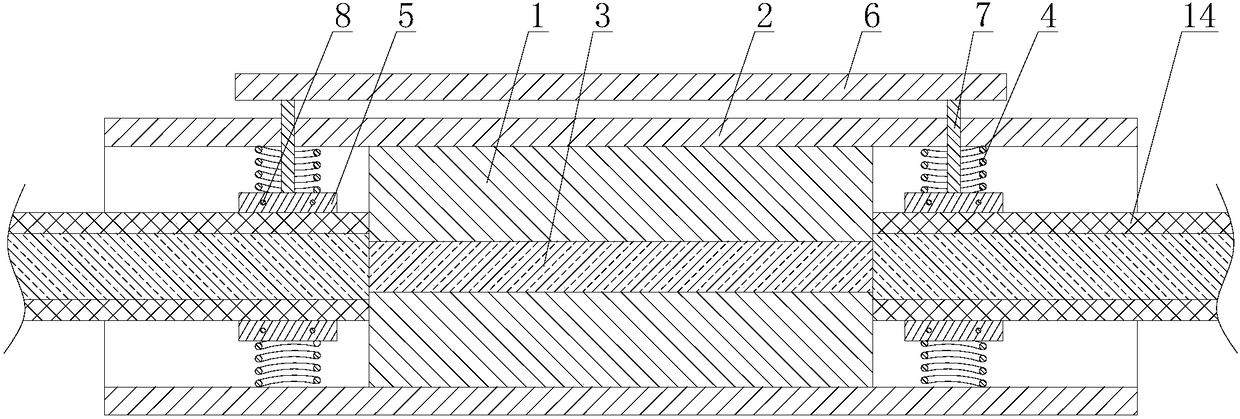

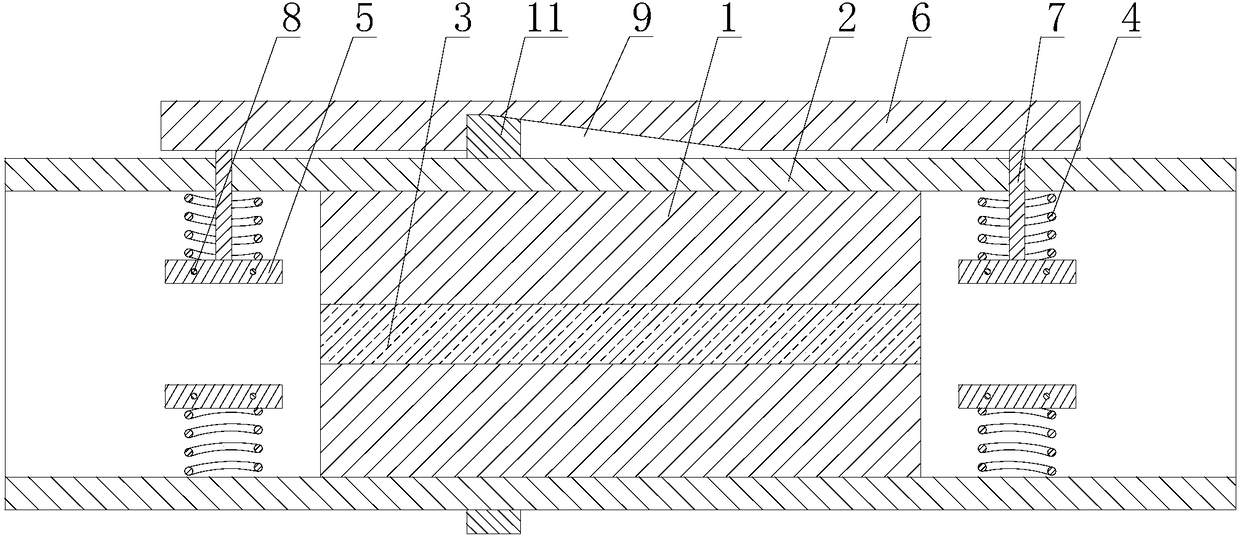

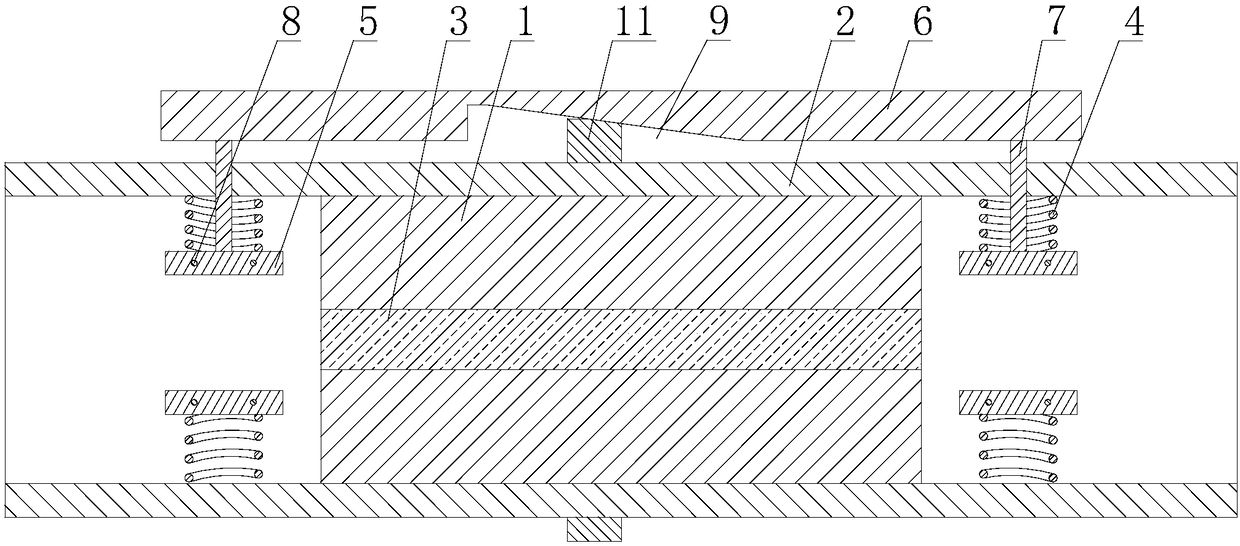

[0031] Such as Figure 1 to Figure 5 As shown, a stamping die connector includes an inner insulating cylinder 1 and an outer insulating cylinder 2 sleeved outside the inner insulating cylinder 1 and arranged coaxially with the inner insulating cylinder 1. The axial length of the outer insulating cylinder 2 is longer than that of the inner insulating cylinder. The axial length of the cylinder 1, and both ends of the inner insulation cylinder 1 are located in the outer insulation cylinder 2, and the inner insulation cylinder 1 is provided with a conductor that is coaxially arranged with the inner insulation cylinder 1 and whose two ends pass through the two ends of the inner insulation cylinder 1 3;

[0032] The inner walls of both ends of the outer insulating cylinder 2 are provided with a plurality of elastic members 4 arranged radially, the free ends of the elastic members 4 are fixedly connected with splints 5, and also include a lifting rod 6 arranged outside the outer insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com