Novel automatic pressure locking steel plate

An automatic pressurization and steel plate technology, applied in the field of medical devices, can solve the problems of fracture nonunion, slow, unfavorable fracture healing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

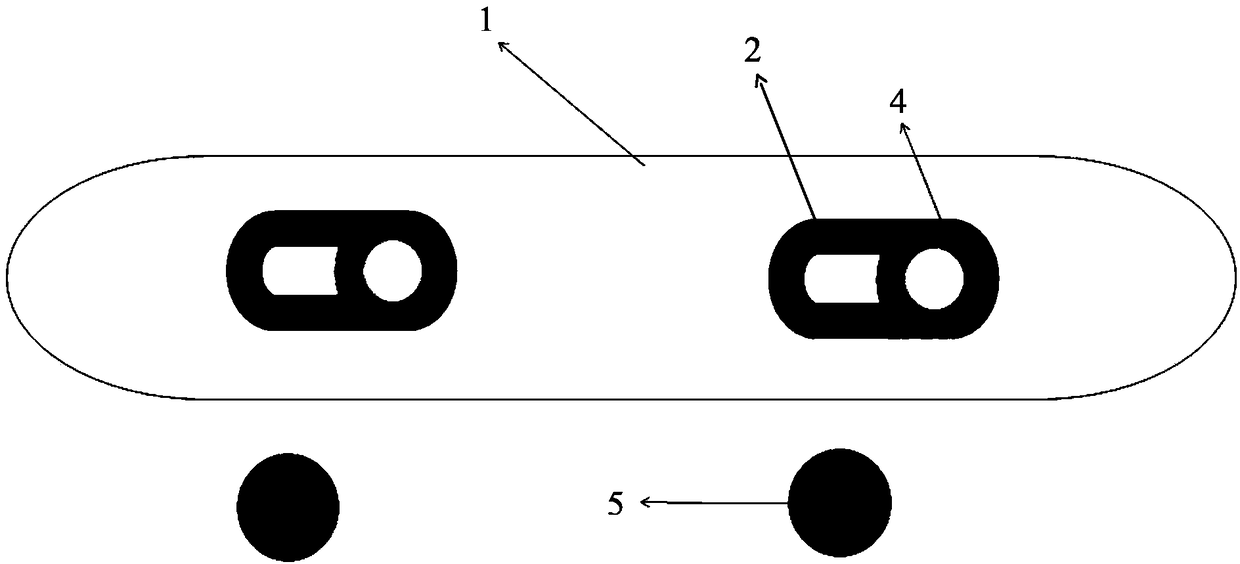

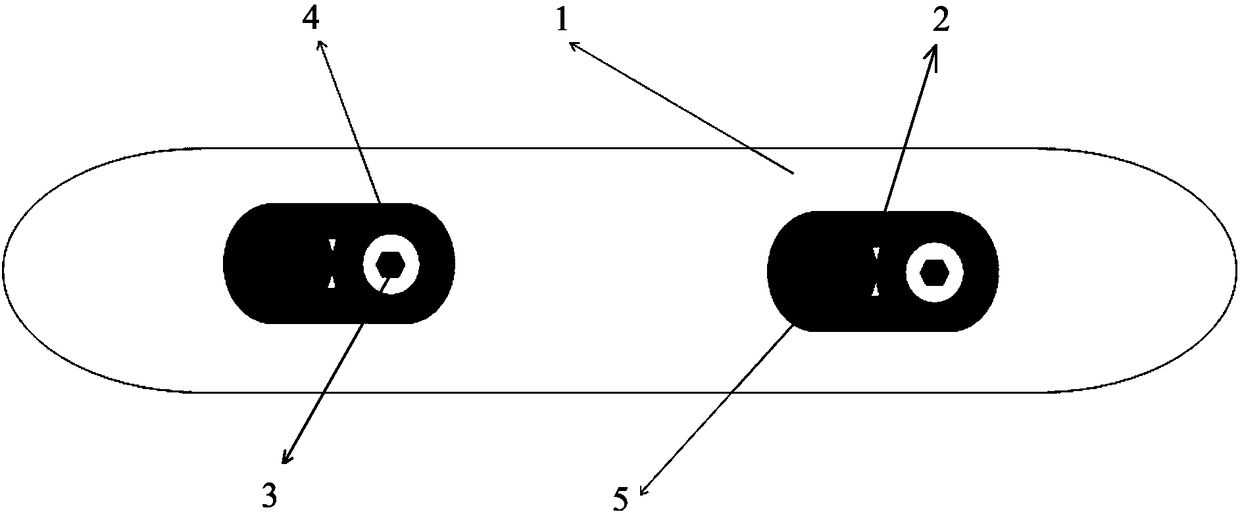

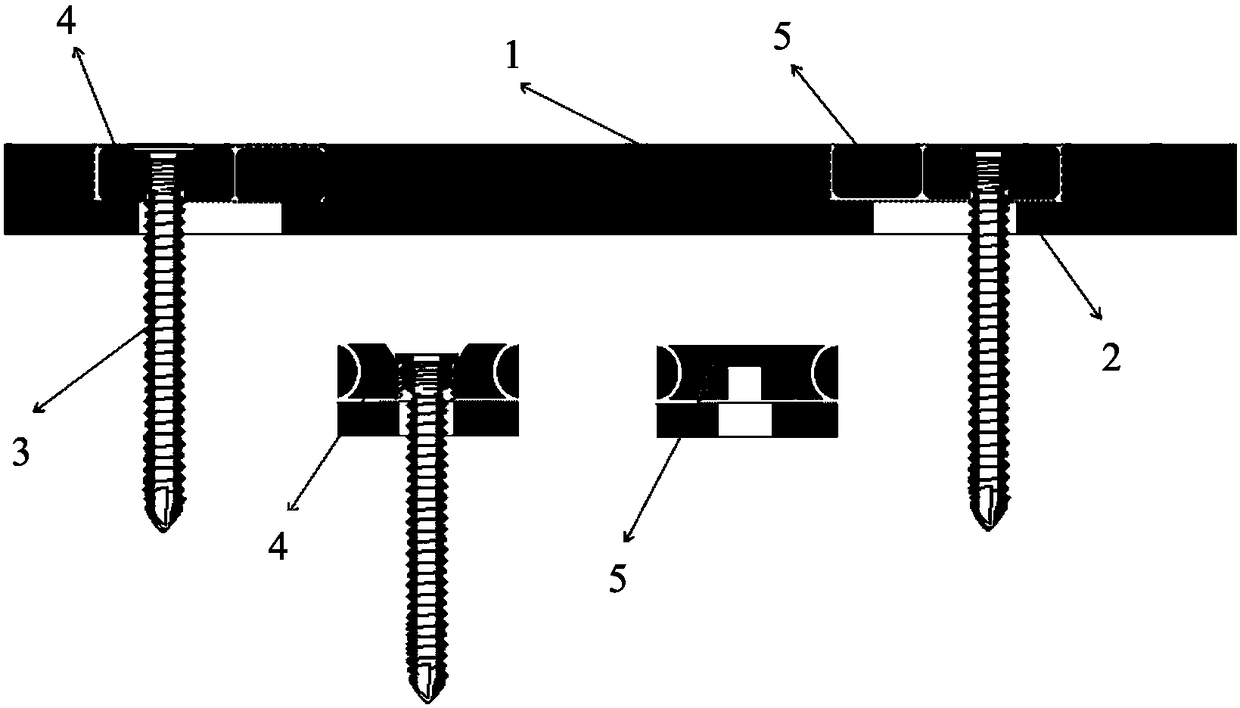

[0067] Such as Figure 1-Figure 4 As shown, the self-pressurizing locking steel plate includes a steel plate 1 , a gasket 4 , buckles 5 , screws 3 and a slidable hole 2 . The steel plate 1 is a plate with four sides, and the four sides are smoothly transitioned, wherein two opposite sides are straight sides, and the other two opposite sides are arc-shaped curved sides, and the two curved sides are consistent with the above-mentioned Two straight sides are tangent. Two slidable holes 2 are provided on the steel plate 1. The slidable holes 2 are stepped structures and are divided into upper and lower parts. The upper hole has a larger cross-sectional area and the lower hole has a smaller cross-sectional area; The outline of the outer edge of the lower hole has four sides, and the four sides are smoothly transitioned, two of which are straight sides, and the other two are arc-shaped curved sides, and the two curved sides are consistent with the The above-mentioned two straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com