Foam sprinkling can for high-pressure cleaning machine

A high-pressure cleaning machine, foam technology, applied in the direction of spraying devices, liquid spraying devices, etc., to achieve the effect of preventing stringing and rotation, good fastening effect, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

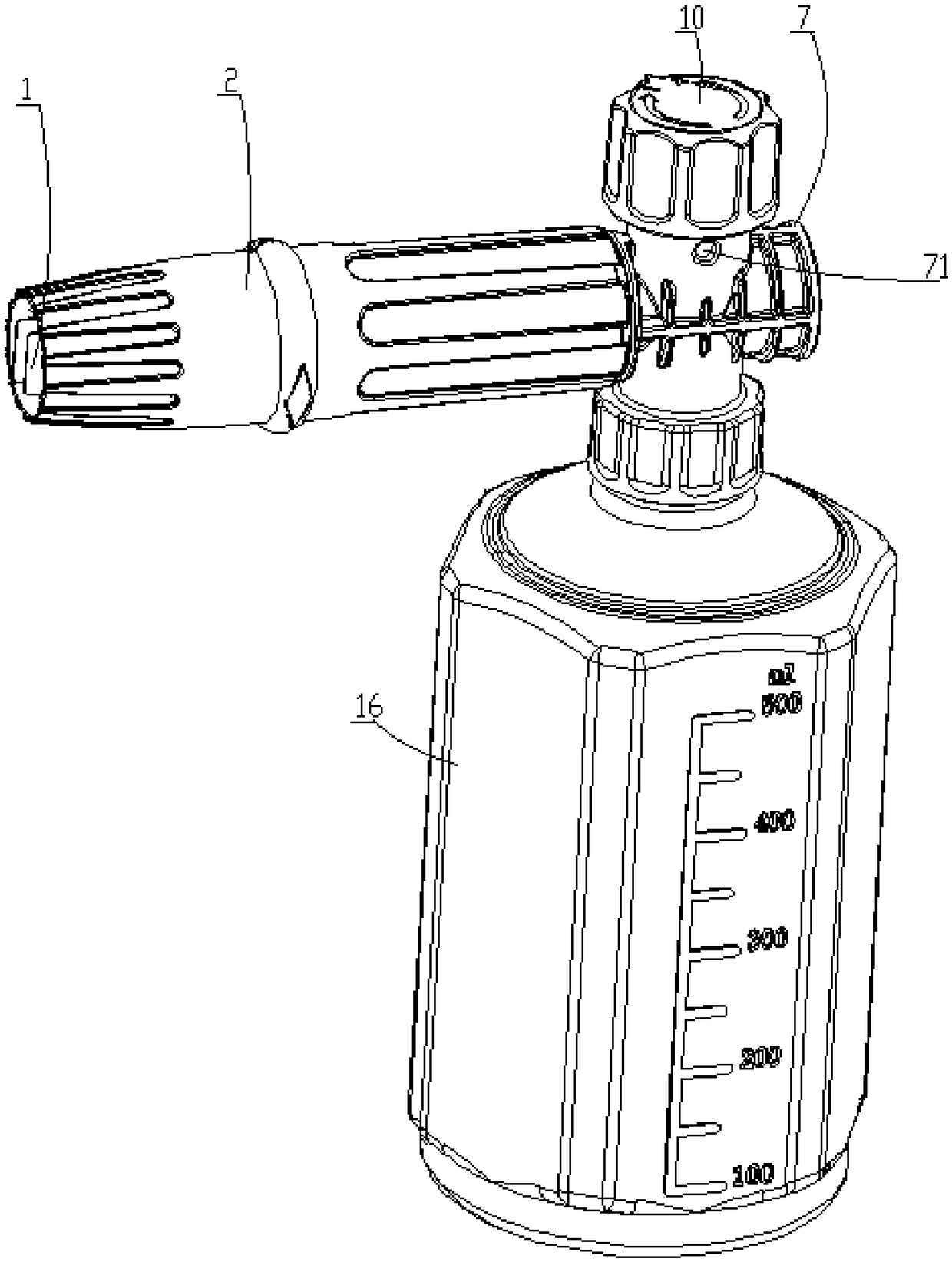

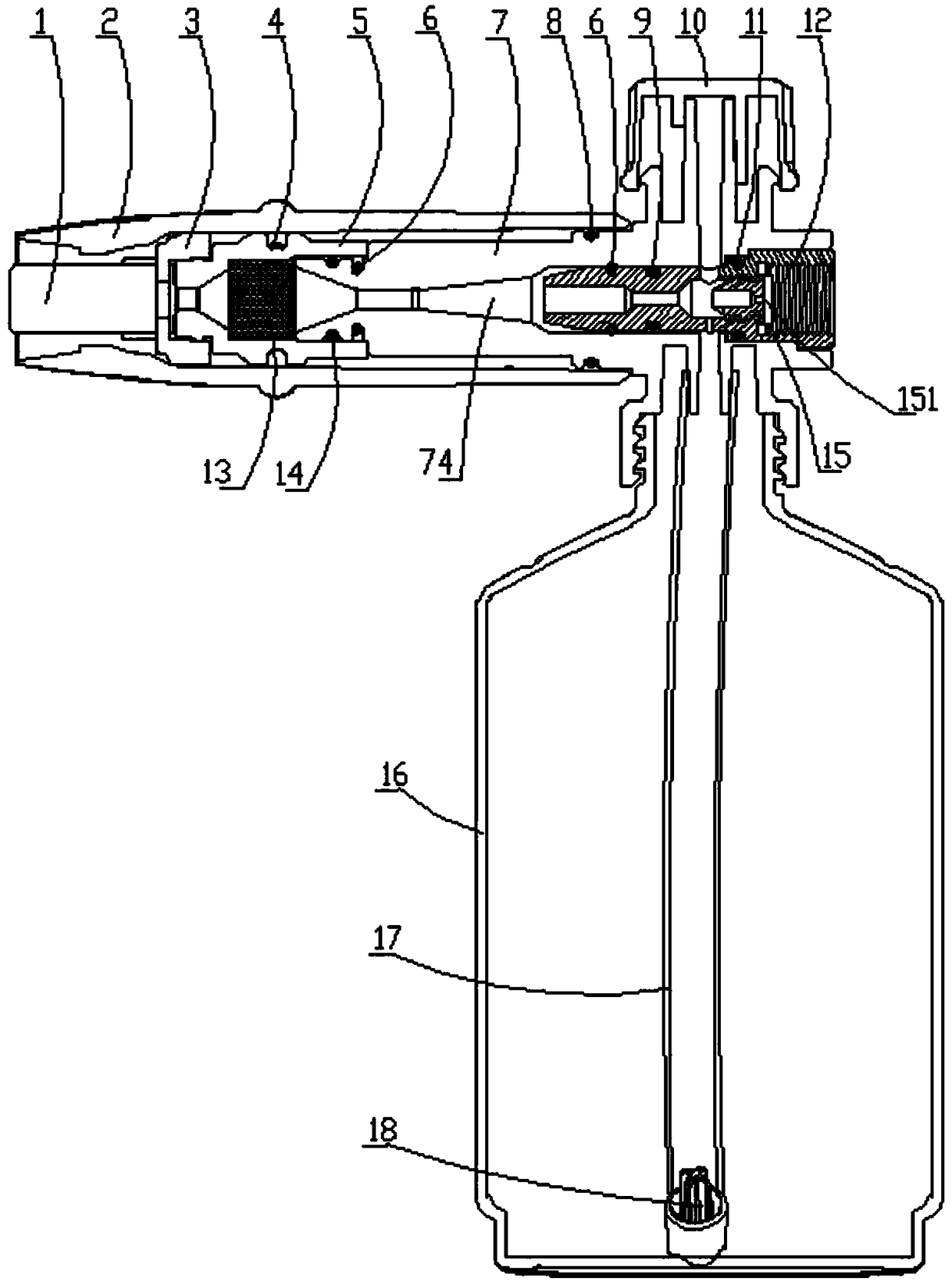

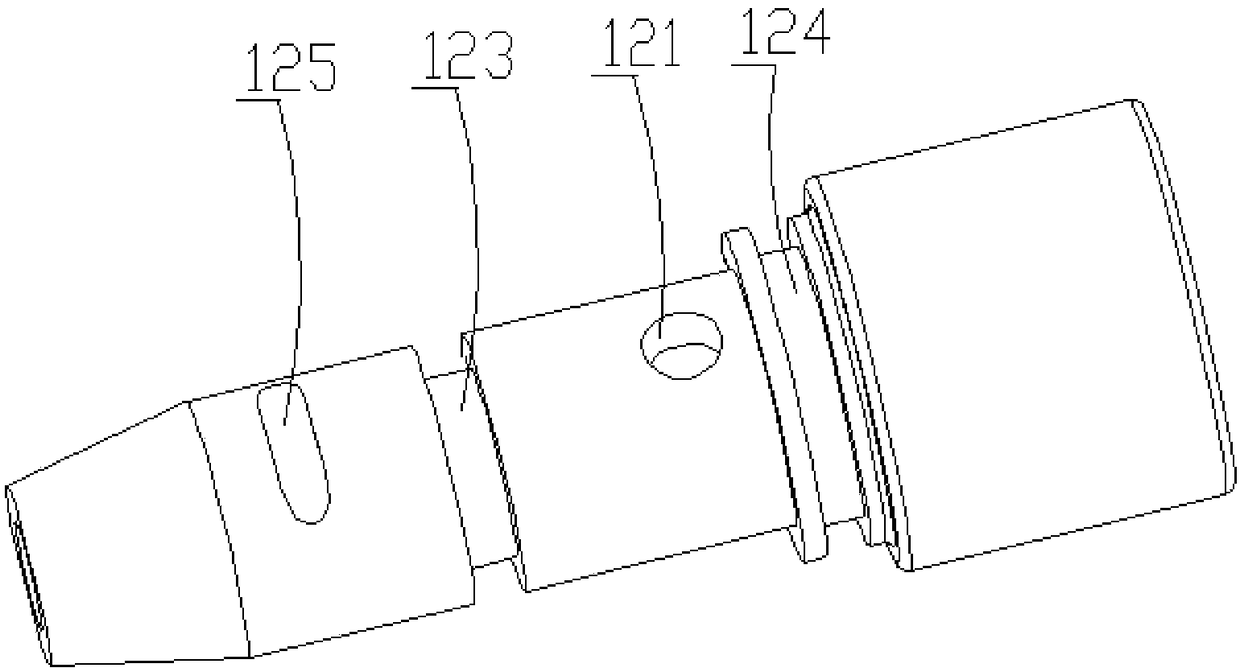

[0057] Such as Figure 1-Figure 10 As shown, the foam spray pot used for high-pressure cleaners includes a liquid storage bottle 16 for containing foam cleaning liquid, a nozzle 5 and a nozzle seat 7 for spraying foam cleaning liquid, and the upper end of the liquid storage bottle 16 has an opening. A soap liquid filter head 18 is fixed on the inner bottom of the bottle 16, and a suction pipe 17 for absorbing foam cleaning liquid is arranged inside the liquid storage bottle 16; The other end of the nozzle is the output end, the lower end of the nozzle seat 7 is fixed at the opening of the liquid storage bottle 16, the side of the nozzle seat 7 is provided with an air inlet 71, the upper end of the nozzle seat 7 has an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com