Automatic sorting structure for projection-weld square nut

A square nut and automatic sorting technology, applied in sorting and other directions, can solve the problems of low welding efficiency and high labor intensity, and achieve the effects of improving production efficiency, reducing labor intensity and reliable sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

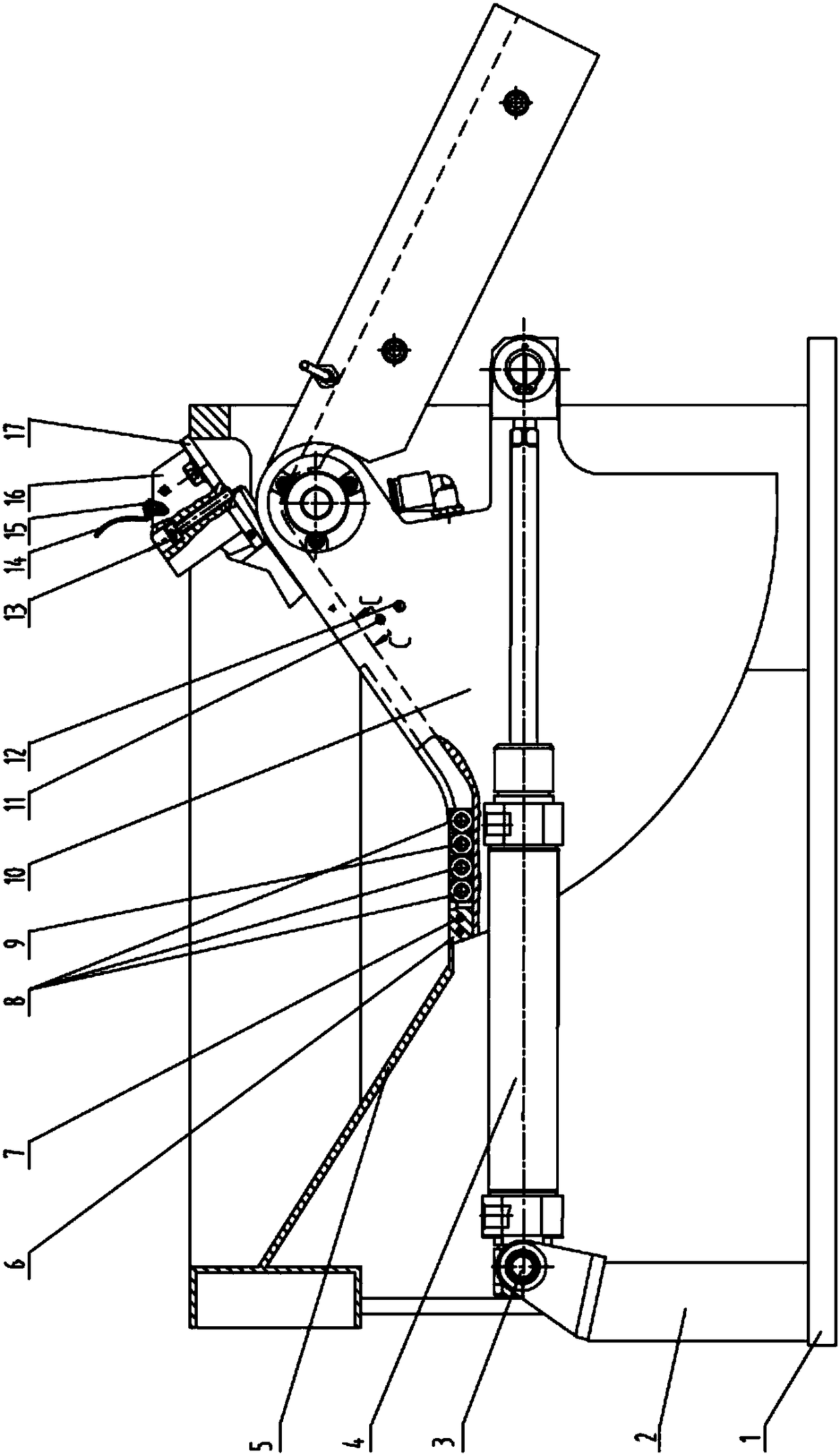

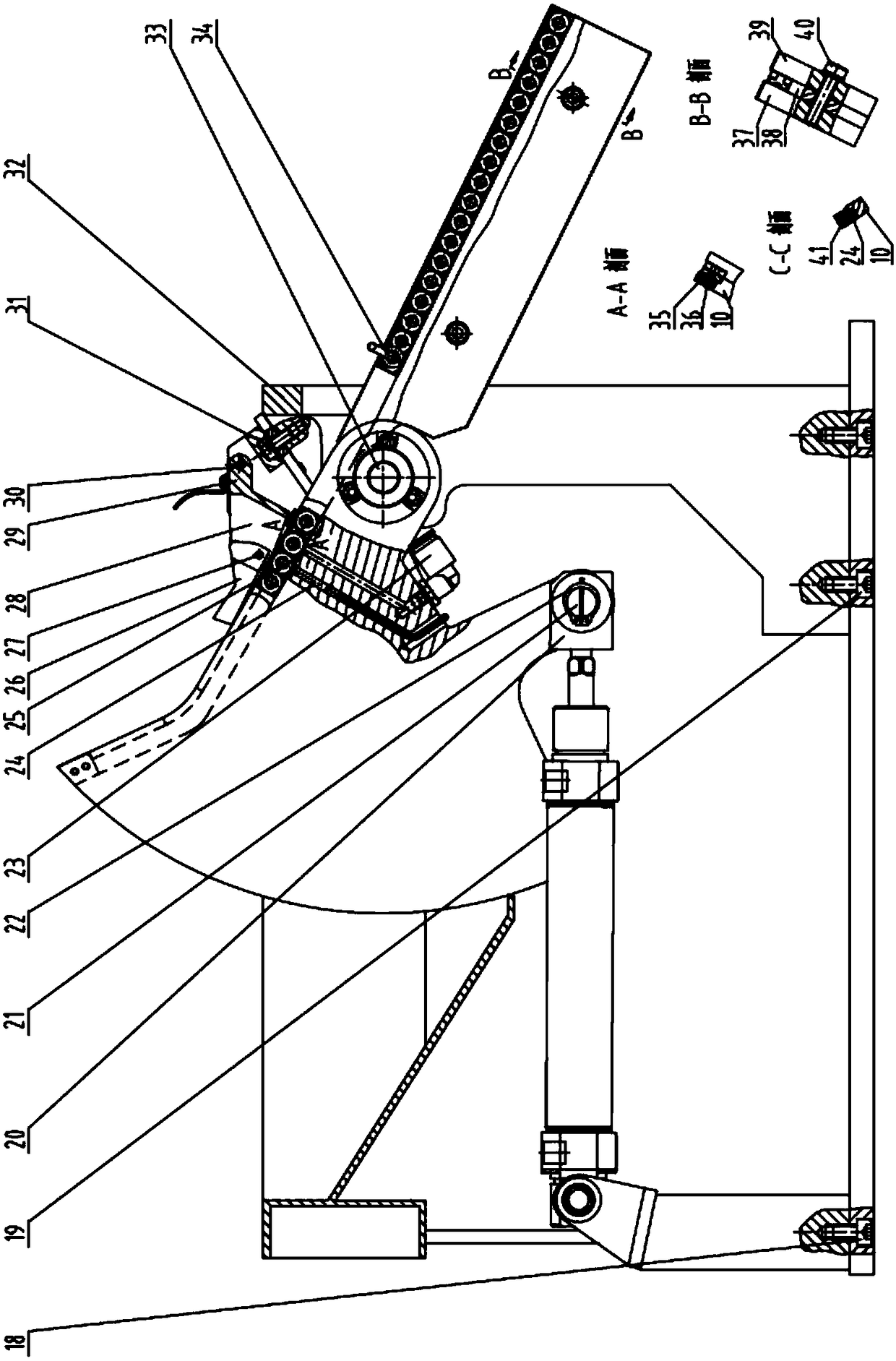

[0017] According to the attached figure 1 , with figure 2 The novelty of the present invention is described further.

[0018] The end face of the fan-shaped plate (10) is provided with a through groove, and one end of the through groove is provided with a stopper (6). The side of the cylinder is provided with a cylindrical stop pin (36), and the cylindrical stop pin (36) is locked and fixed by the set screw (35) on the end face of the sector plate (10), and the bottom of the channel of the sector plate (10) is provided with a proximity switch (24 ) and the air hole (25), the proximity switch (24) is locked and fixed with the set screw (41) on the side of the sector plate (10), and the side of the sector plate (10) is provided with a proximity switch signal observation hole (12), the Also be provided with two pin holes on the fan-shaped plate (10) side, one is the pivot pin hole that the fan-shaped plate (10) rotates, and the other is the pin hole connected with the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com