Aluminum and aluminum alloy thin-wall pipe automatic sorting method based on eddy current testing

A thin-walled pipe and eddy current detection technology, which is applied in sorting and other directions, can solve problems such as low efficiency and poor reliability, and achieve the effects of rapid information processing, avoiding errors, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

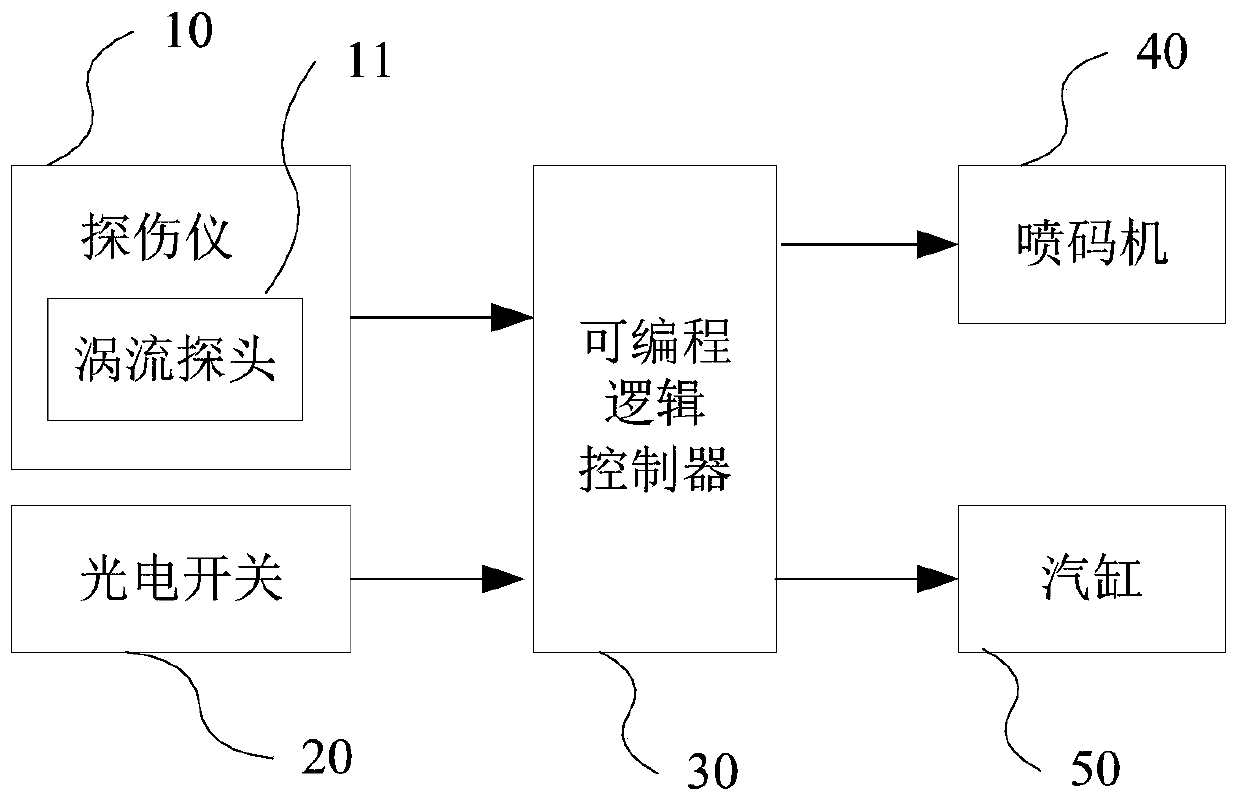

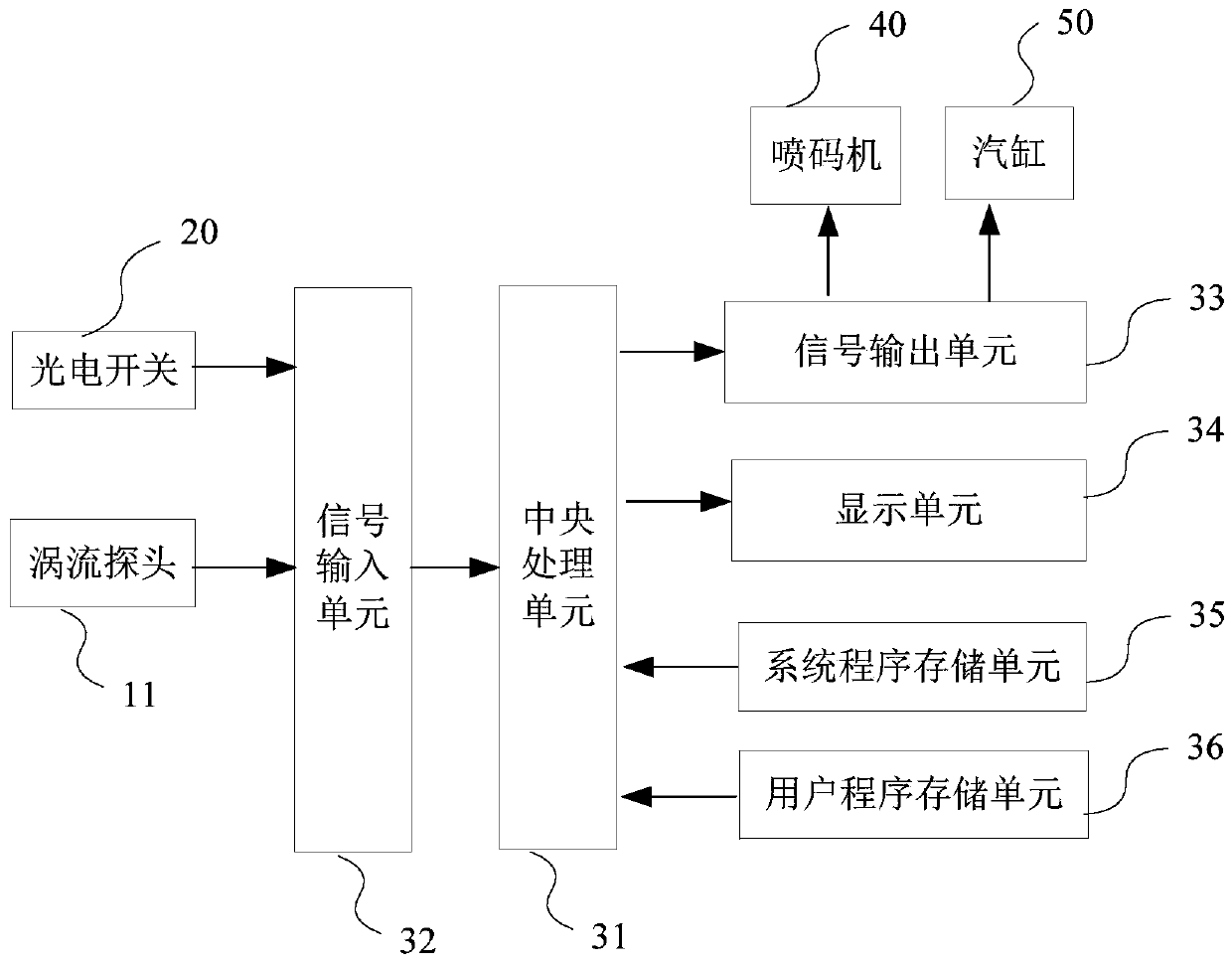

[0034] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a method for automatic sorting of aluminum and aluminum alloy thin-walled pipes based on eddy current detection, including:

[0035] The eddy current probe 11 and the photoelectric switch 20 of the flaw detector 10 are arranged on the conveying equipment of the thin-walled pipe,

[0036] The eddy current probe 11 is arranged in the detection area of the conveying equipment, and is used to detect the quality information of the thin-walled pipe in the detection area; the photoelectric switch 20 is used to determine the time when the thin-walled pipe enters and leaves the detection area;

[0037] Described automatic sorting method comprises:

[0038] The flaw detector 10 transmits the quality signal obtained by the eddy current probe 11 to the programmable logic controller 30;

[0039] The photoelectric switch 20 transmits the time when the thin-walled pipe enters and leaves t...

specific Embodiment

[0059] Specific embodiment: first debug the instrument, set the optimal flaw detection parameters of the flaw detector 10, so as to be able to accurately detect aluminum and aluminum alloy thin-walled pipes, and accurately mark the natural flaws that exceed the corresponding standards, and for qualified products and Unqualified products are accurately sorted.

[0060] 1) Make comparison sample tubes according to the corresponding standards, and use the comparison sample tubes to debug instruments and equipment until the best flaw detection parameters, and select appropriate pneumatic control devices, photoelectric switches, cylinders, etc.;

[0061] 2) Make sure that the marking device is reliable in action, using ink marks as identifiable marks, and marking the position of natural damage exceeding the standard is accurate;

[0062] 3) Confirm that the action of the sorting device for qualified and unqualified products is accurate and reliable;

[0063] After the above adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com