Improved bridge equipment

An improved, bridge technology, used in metal processing equipment, drilling/drilling equipment, boring/drilling devices, etc. tremors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

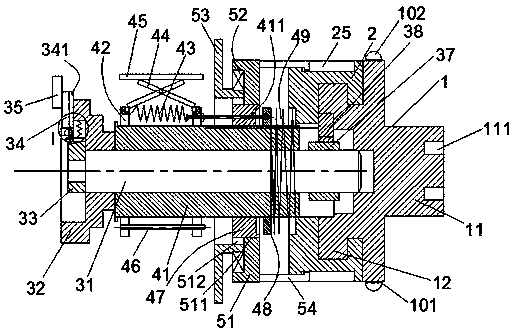

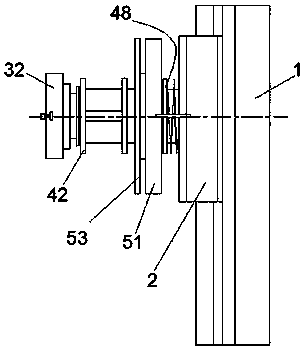

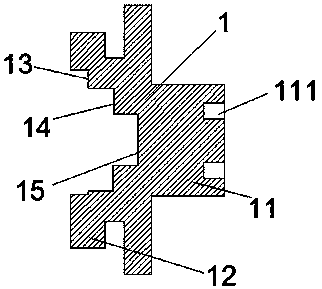

[0030] Such as Figure 1-Figure 8 As shown, an improved bridge equipment of the present invention includes a clamping part 1, a frame body 2, a vertical manipulation device, a horizontal manipulation device and a clamping device, and a long rod 11 is arranged on the left side of the clamping part 1 , the upper and lower ends of the right side are respectively provided with a guide strip 12 in the front and rear directions, and a straight groove group consisting of a first straight groove 13, a second straight groove 14 and a third straight groove 15 is arranged in the front and rear direction of the center of the right side, so The side of the long rod 11 is also provided with a plurality of clamping grooves 111, and the right side of the frame body 2 is provided with a guide recessed groove 21 in the front and back direction, which is slidingly matched with the guide bar 12, and is in contact with the guide bar 12. The guide recessed groove 21 is centered up and down and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com