Clamping device for welding of middle grooves

A technology of clamping device and pressing device, applied in welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of low efficiency, long time-consuming clamping and positioning, etc. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

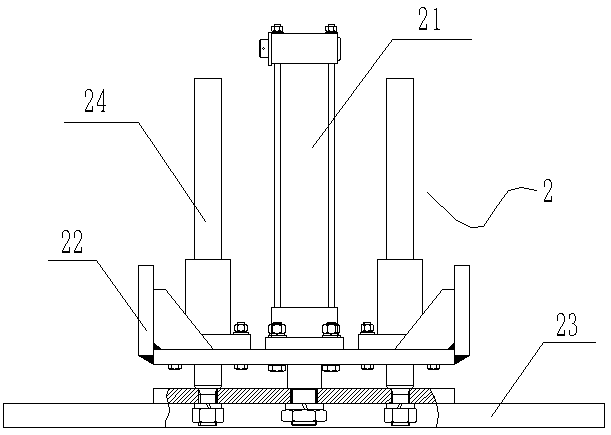

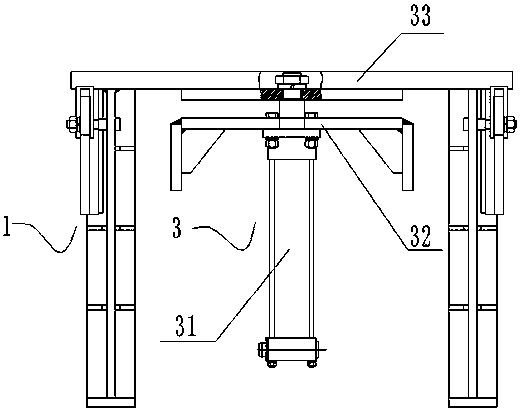

[0028] Embodiment: A clamping device for middle slot welding, including an upper pressing device and a lower pressing device oppositely arranged, and a deflection adjustment device is fixedly connected to the opposite sides of the lower pressing plate of the lower pressing device respectively, and the upper pressing device The tightening device and the lower pressing device can be connected with the external platform, or can form a device by itself; combined with the transportation, turning and other tooling during the welding of the middle groove, the external platform can be a transportation platform.

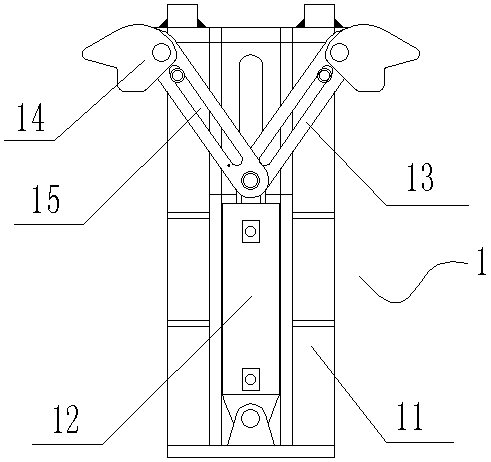

[0029] Such as figure 1 Any deviation adjustment device 1 shown includes a vertical frame 11, a deviation adjustment oil cylinder 12, a set of sliding plates 13 and a set of deviation adjustment blocks 14, and a set of sliding plates 13 includes two strip-shaped sliding plates, each of which is long The strip-shaped sliding plate 13 is provided with a strip-shaped sliding gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com