Car seat with buffering equipment

A technology for car seats and buffer equipment, applied in vehicle seats, movable seats, vehicle parts, etc., can solve the problems of passenger collision, reduce the safety of passenger seats, avoid slippage, increase contact surface, The effect of protecting life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

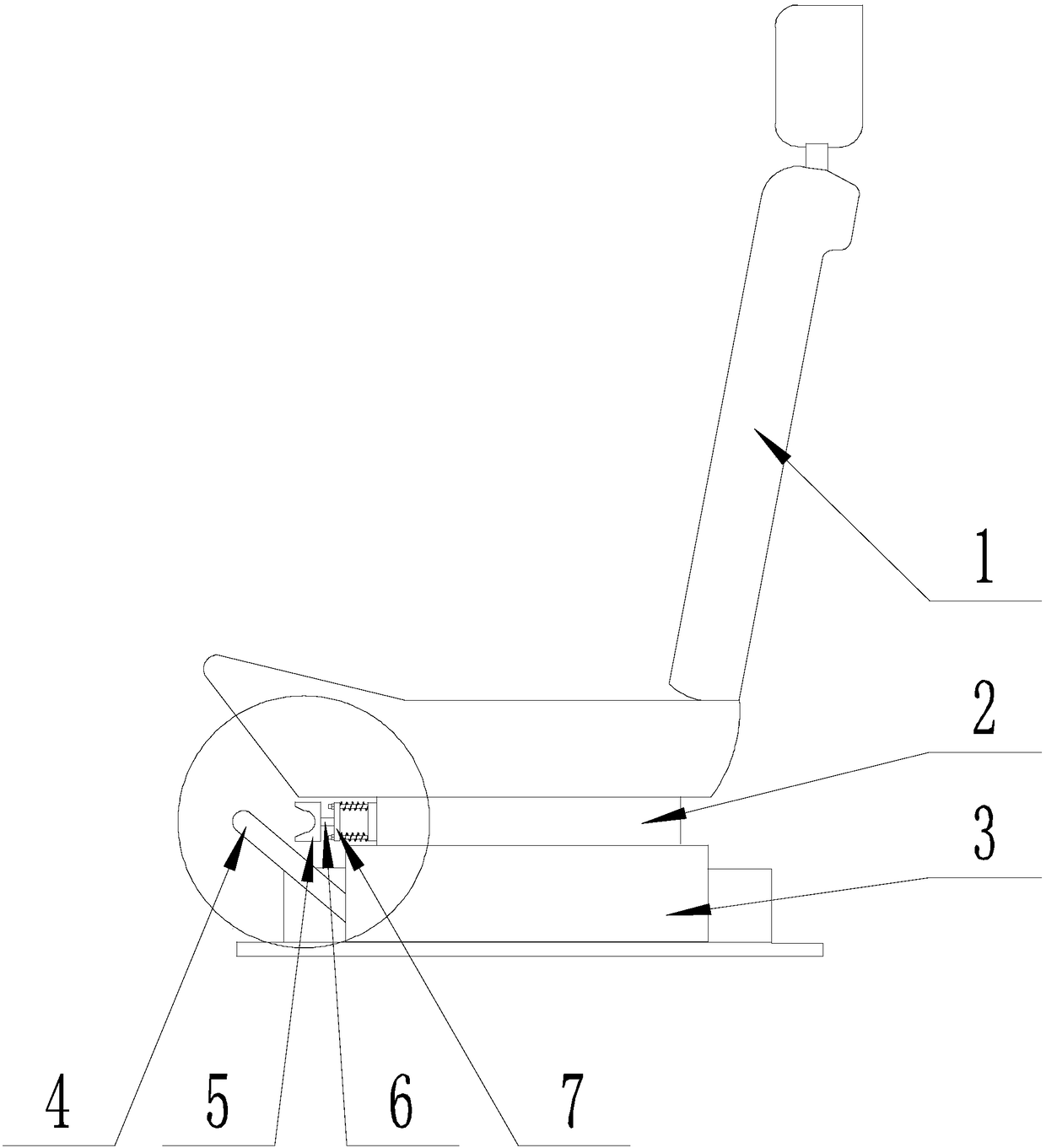

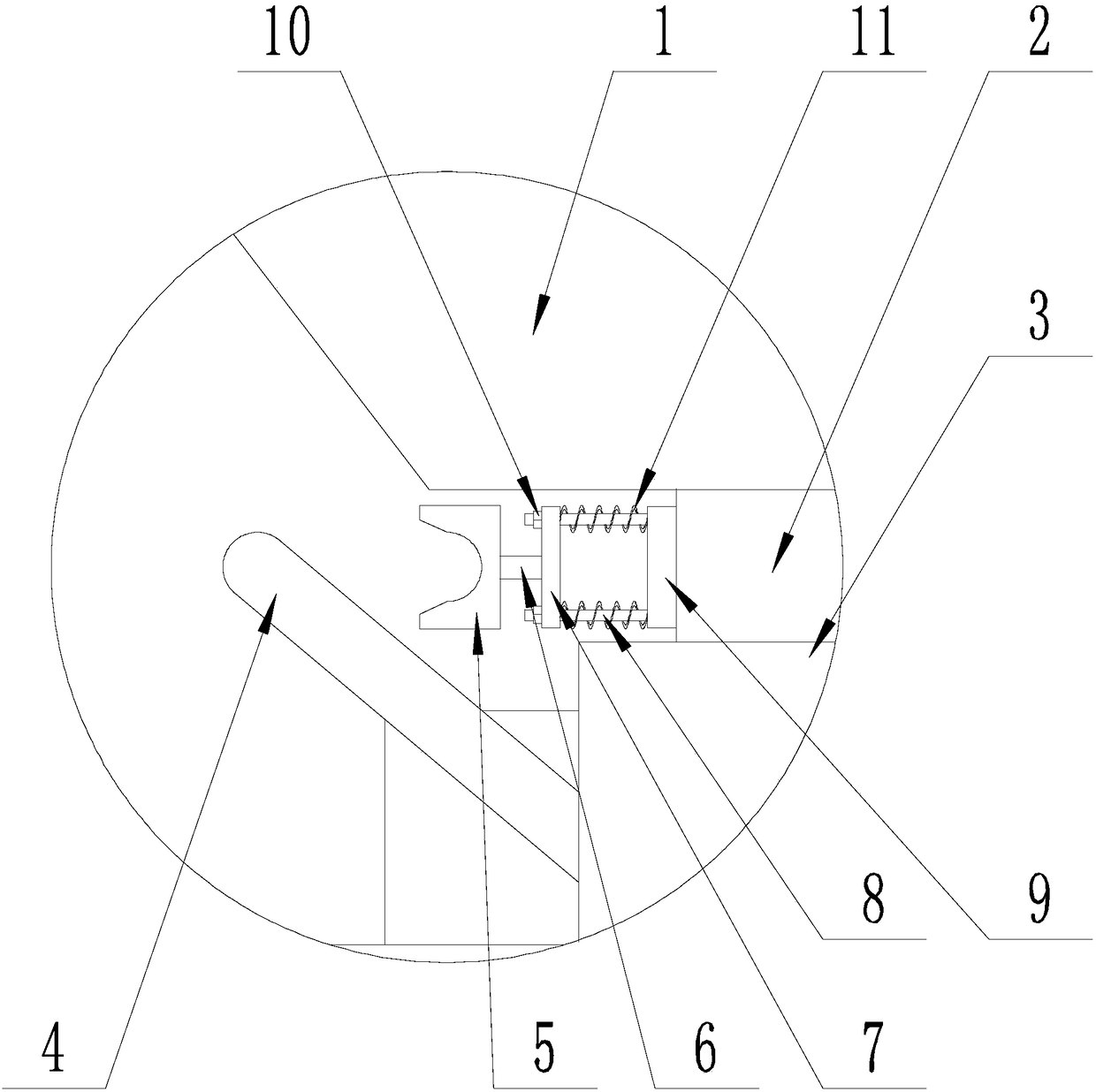

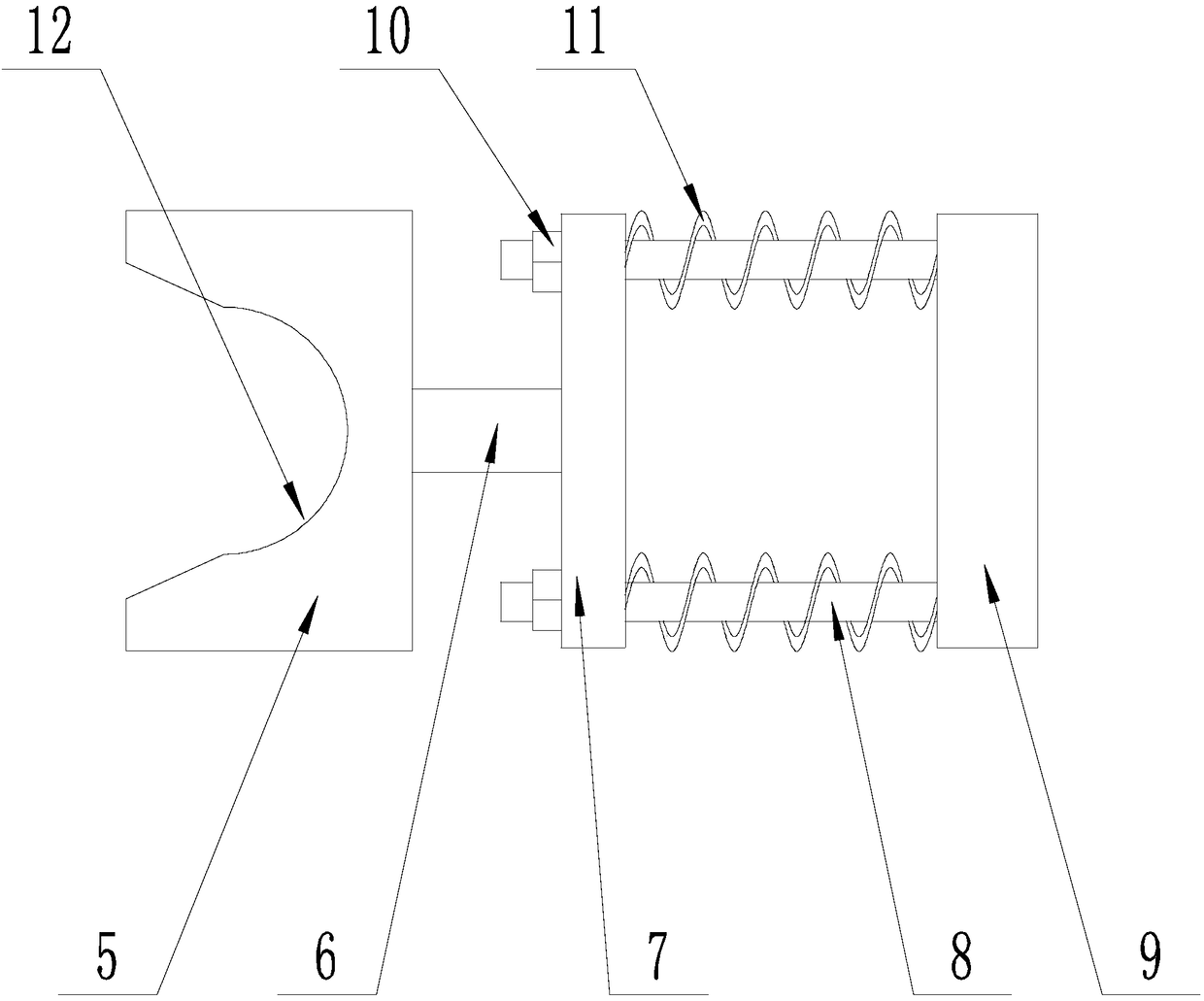

[0039] Such as Figure 1-Figure 3 As shown, the present invention is provided with the automobile seat of cushioning device, comprises the automobile seat body 1, base 2, seat slide rail 3 and U-shaped pull bar 4 that are connected in sequence, and described automobile seat body 1 is set by the sliding of base 2 On the seat slide rails 3, the ends of the pull rods 4 are respectively connected to a seat slide rail 3, and control the locking state of the locking device of the seat slide rails 3, on the base 2 close to the pull rods 4 One end of the buffer assembly is provided with a buffer assembly, which includes a contact block 5, a connecting shaft 6, a moving plate 7, a supporting shaft 8 and a fixed plate 9 connected in sequence, and one end of the connecting shaft 6 is connected with the contact block 5, and the connecting shaft The other end of 6 is connected with moving plate 7, and one end of said supporting shaft 8 is connected with fixed plate 9, and the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com