Wingtip rotor wing applied to unmanned aerial vehicle

A drone and wingtip technology, applied in the field of wingtip rotors, can solve the problems of complex rotor structure, weakening the lift of drones, reducing the stability of drones, etc., and achieve the effect of reducing weakening and induced drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

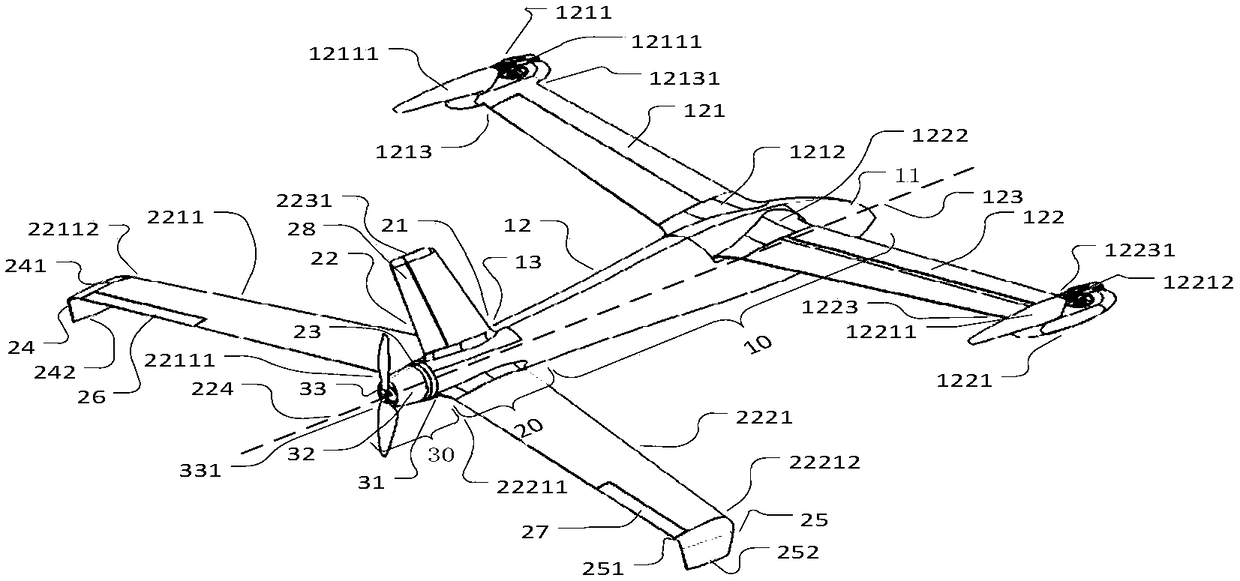

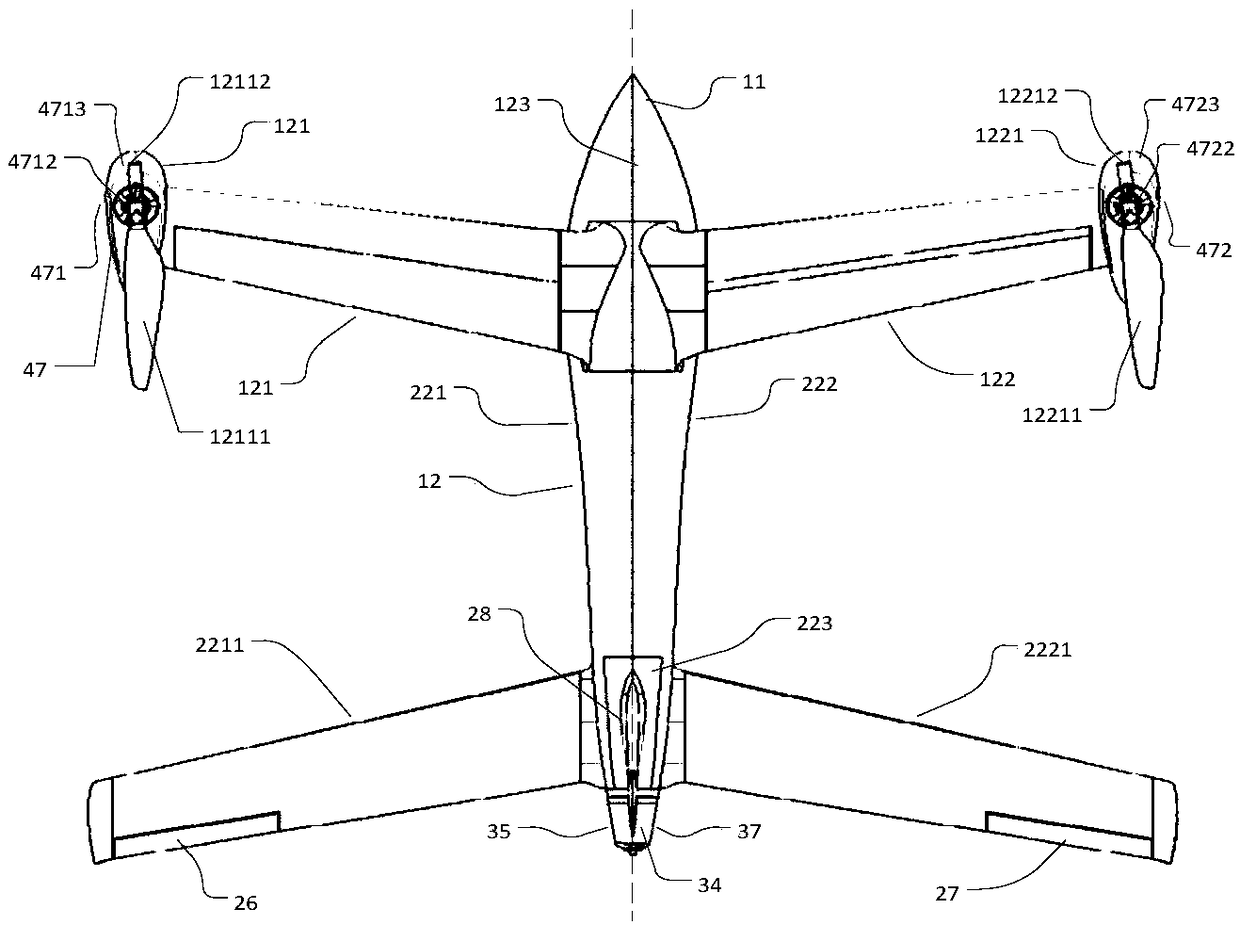

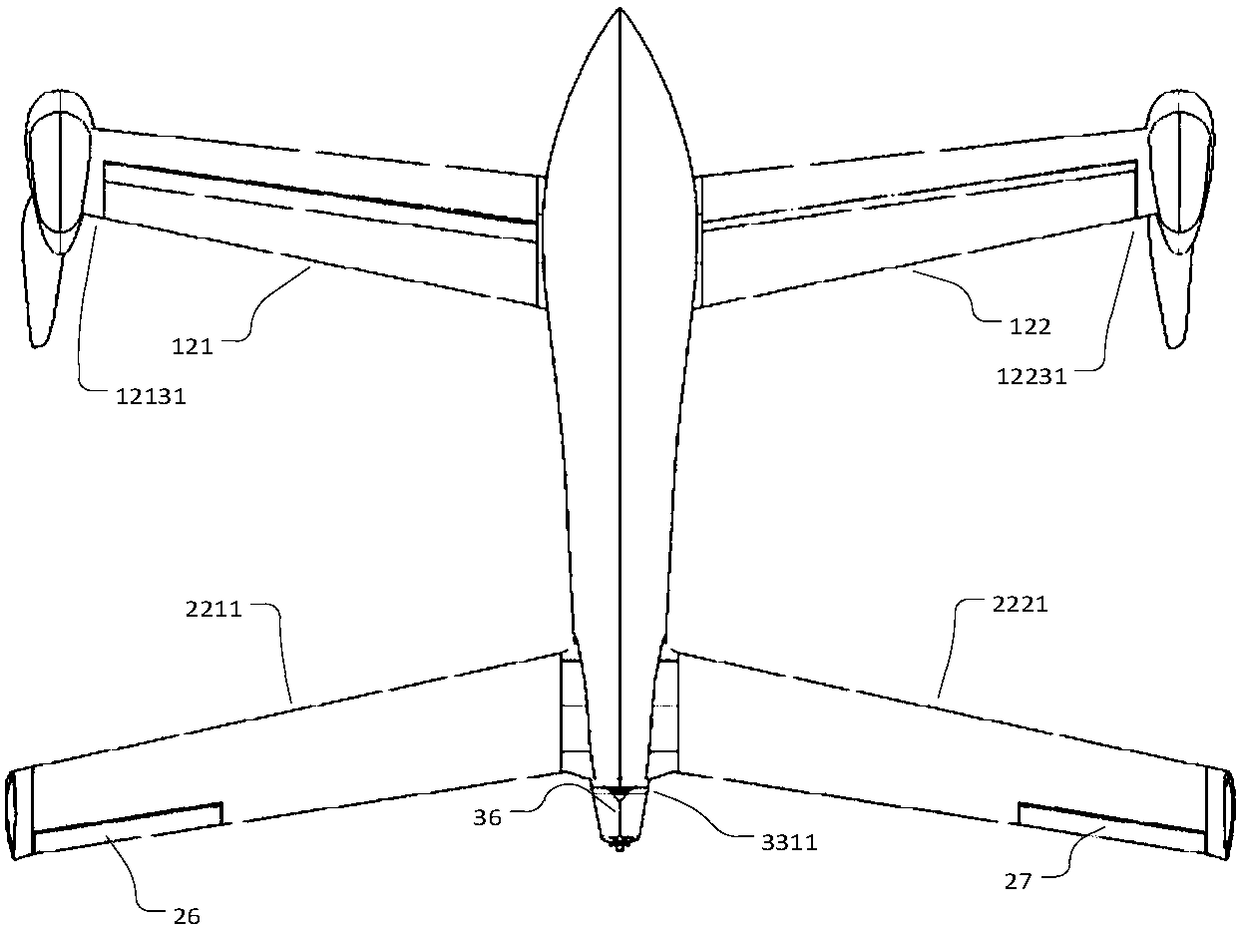

[0027] The invention discloses a wingtip rotor applied to an unmanned aerial vehicle. The first rotating blade and the first counterweight are respectively fixedly connected to the first rotor shaft so that the first rotating blade and the first counterweight are relative to the first The rotor shafts are symmetrically distributed, and the first rotor shaft is perpendicular to the rotation plane of the first rotating blade; the second rotating blade and the second counterweight are fixedly connected to the second rotor shaft respectively, so that the second rotating blade and the second counterweight The blocks are distributed symmetrically with respect to the second rotor axis, which is perpendicular to the plane of rotation of the second rotary blade. At the same time, by fixedly connecting the first wingtip fastening end with the first rear opening end, the first wingtip opening end of the first winglet deviates from the first rear opening end, and is fastened to the first w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap