Water purification machine and water purification method thereof

A water purifier and water purification technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Scaling and other problems can be achieved to reduce the TDS value, the service life is not easy to decline, and the effect of solving the rapid decline in service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

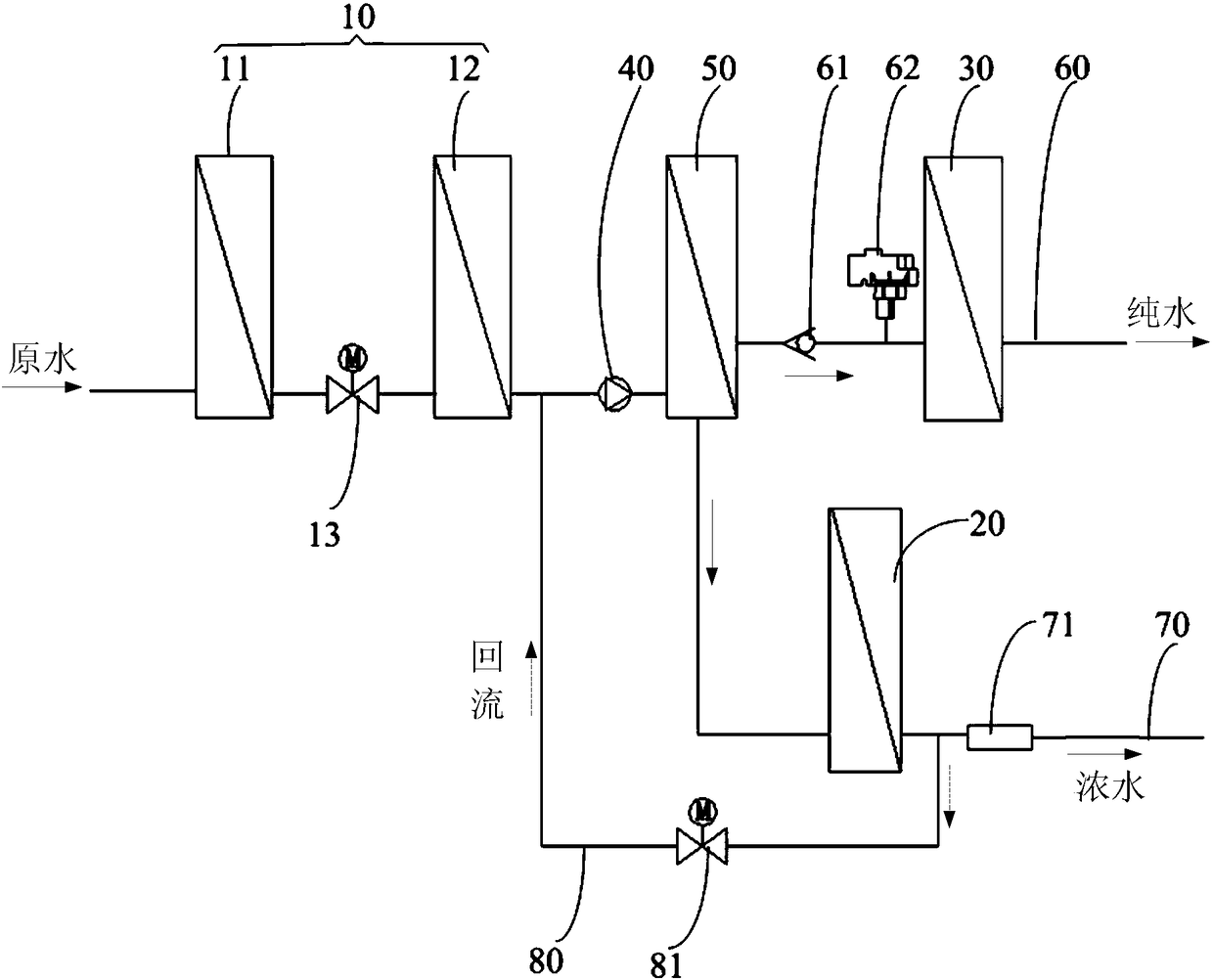

[0057] figure 2 It is a schematic diagram of the block structure of the water purifier provided in Embodiment 1 of the present invention.

[0058] Among them, the water purifier provided in this embodiment achieves the purpose of reducing the TDS value while achieving a high recovery rate, so that the service life of the reverse osmosis membrane is not easily reduced rapidly and the combined flushing solenoid valve is not easy to scale.

[0059] Among them, in this embodiment, such as figure 2 As shown, the water purifier includes: a first filter unit 10, a reverse osmosis membrane device 50, a pressurization device 40 and a combined flushing solenoid valve 71, wherein the booster device 40 is located between the first filter unit 10 and the reverse osmosis membrane device 50 On the connected pipeline, the combination flushing solenoid valve 71 is arranged on the discharge pipe 70 connected to the concentrated water outlet of the reverse osmosis membrane device 50, and the ...

Embodiment 2

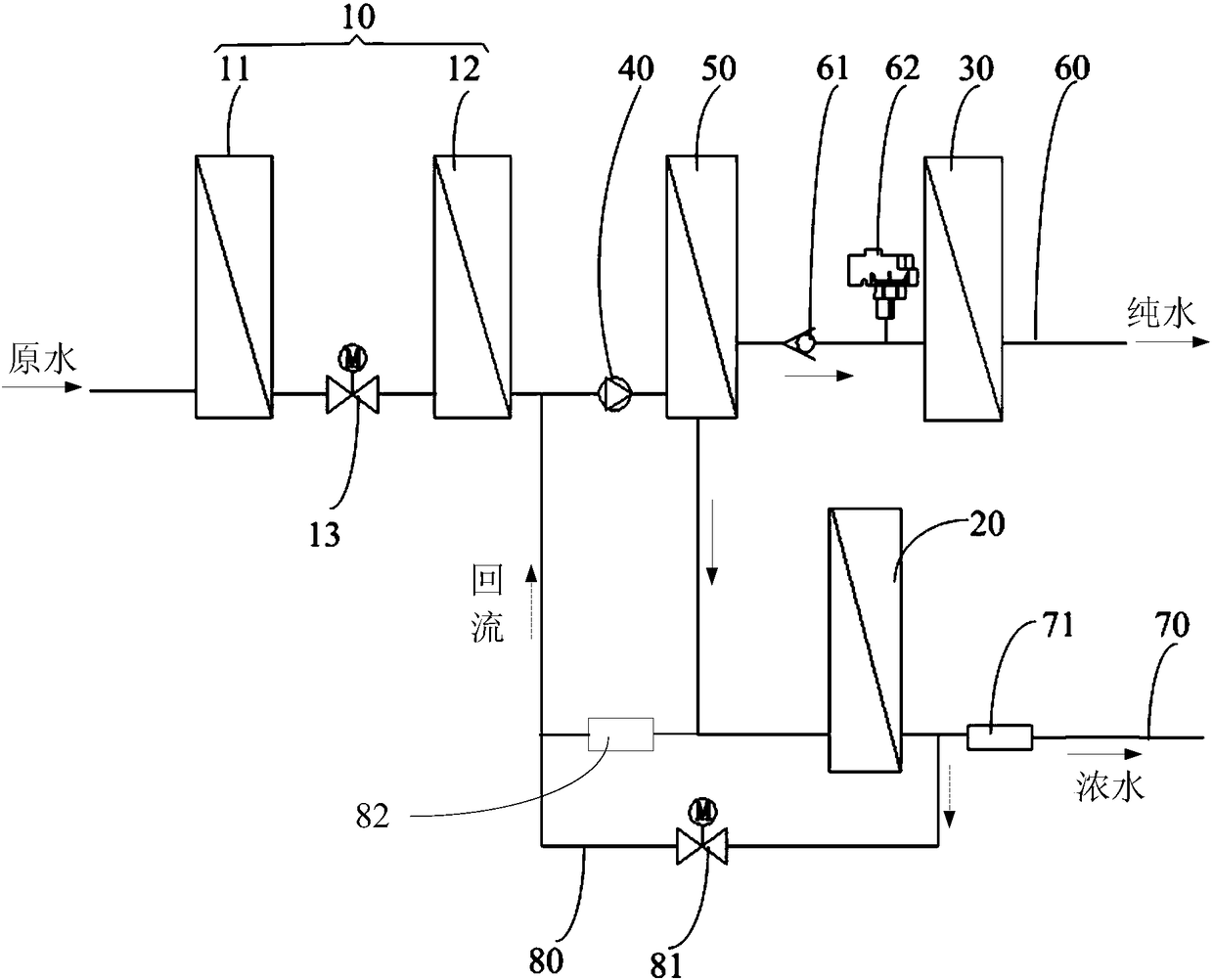

[0075] image 3 It is a schematic diagram of the block structure of the water purifier provided in Embodiment 2 of the present invention, wherein, the difference between this embodiment and the above-mentioned embodiment is: in this embodiment, such as image 3 As shown, it also includes: a waste water proportioner 82 (also known as waste water ratio), the water inlet end of the waste water proportioner 82 communicates with the discharge pipe 70 between the reverse osmosis membrane device 50 and the second filter unit 20, that is, the waste water proportion The water inlet end of the device 82 is connected with the concentrated water outlet of the reverse osmosis membrane device 50, and the water outlet end of the waste water proportional device 82 is connected with the return pipe 80 between the backflow control valve 81 and the pressurizing device 40, that is, the waste water ratio The water outlet end of the device 82 is connected with the water inlet end of the pressurizat...

Embodiment 3

[0078] Figure 4 It is a schematic flow chart of the water purification method of the water purifier provided in Embodiment 3 of the present invention. In this embodiment, the water purifier described in any of the above embodiments is used for water purification, specifically as Figure 4 and figure 2 Shown, water purification method comprises the steps:

[0079] Step 301, when the water pressure in the water inlet pipeline of the water purifier reaches the preset pressure value, start the booster device of the water purifier and the control valve on the water inlet pipeline, and close the combined flushing solenoid valve and return pipe of the water purifier On the control valve, so that the water purifier enters the water purification mode.

[0080] Wherein, in this embodiment, when the water purifier starts purifying water, when the pressure in the water inlet pipeline reaches the preset pressure value, specifically, when the pressure in the water inlet pipeline reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com