Double-column internal cascading type graphitization production method for ultrahigh-power graphite electrode

A production method and graphite electrode technology are applied in the production field of roasted graphite electrodes, which can solve the problems of furnace loading method and process parameter control differences, and achieve the effects of smooth production organization, high single furnace productivity and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment the present invention is further described.

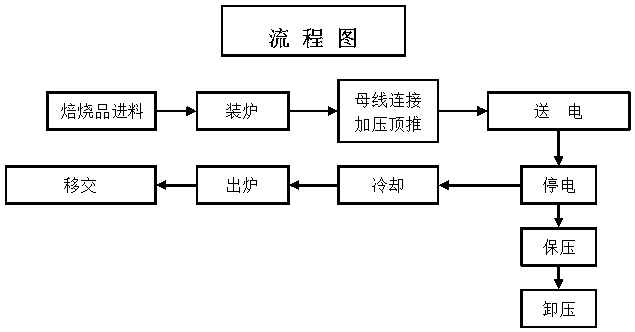

[0041] see Figure 1-Figure 3 , Embodiment 1, the equipment used in this embodiment is an inner string graphitization furnace, including charging of roasted products, furnace loading, busbar connection and pressurization and pushing, power failure, cooling, furnace release and handover, and is characterized in that: it also includes power transmission ,details as follows:

[0042] 1) Roasted product feed;

[0043] 2) Furnace loading;

[0044] 3) Bus connection and pressurized push;

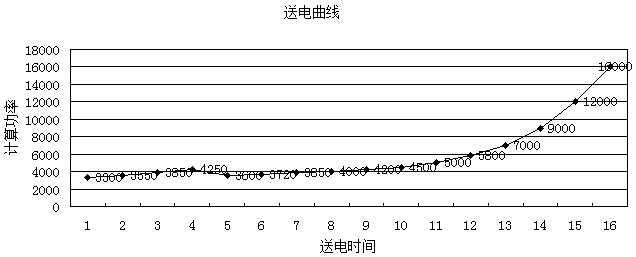

[0045] 4) Power transmission, through the control of the power curve to control the temperature rise;

[0046] 5) Power failure, pressure maintenance and pressure relief;

[0047] 6) cooling;

[0048] 7) out of the oven;

[0049] 8) Handover.

[0050] The pressure in the inner series graphitization furnace is 5.5MPa.

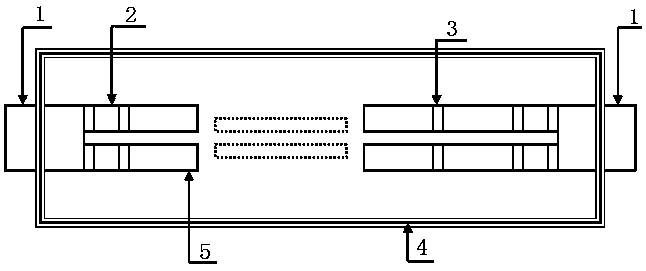

[0051] The furnace loading method of the step 2) is as follows: two conductive ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com