Flushing double-sided plough tooth for dredging rake head

A flushing and harrowing head technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of insufficient soil breaking capacity, high cost, and high labor intensity, and achieve improved The effect of breaking ground, strengthening the ability of breaking ground, and increasing the amount of ground breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

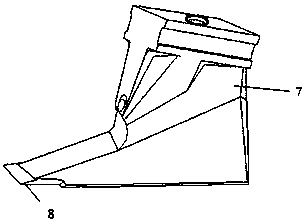

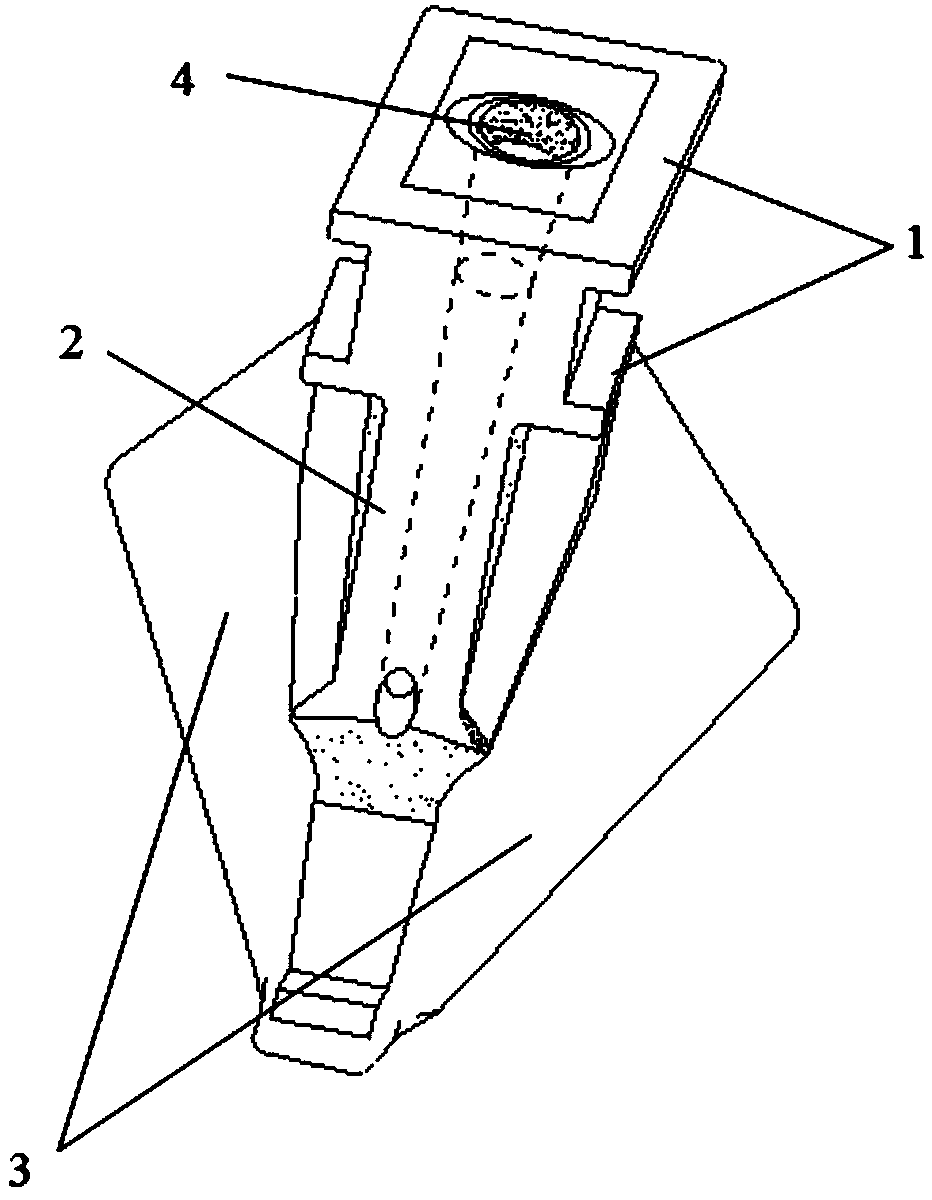

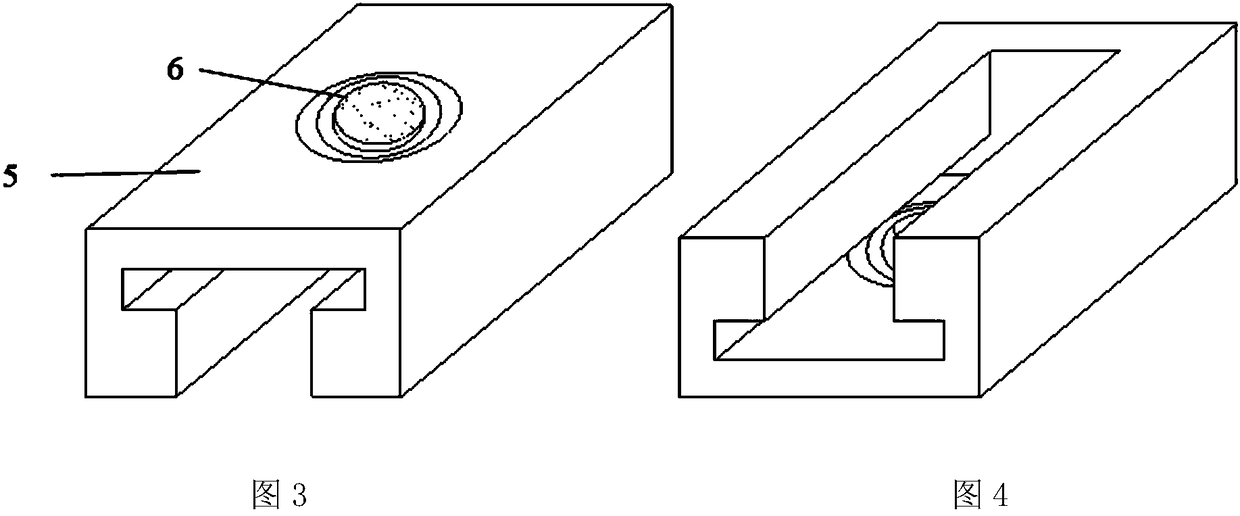

[0031] A double-sided plow tooth with flushing for a dredging rake head, which is composed of a tooth seat and teeth. The tooth seat is installed at the position of the wear-resistant block of the rake head, and the teeth are installed on the tooth seat; The tooth wings are extended backwards; there is a flushing channel in the middle of the tooth stem. The cross-section of the tooth seat is an inverted concave structure; the teeth are divided into three parts: the tooth top, the tooth stem and the tooth wing. Both sides are mutually symmetrical structures.

[0032] See attached picture. The double-sided plow teeth with flushing for the dredging rake head are composed of tooth base 5 and tooth 7. The tooth base 5 is installed at the position of the wear-resistant block of the rake head, and the tooth 7 is installed on the tooth base 5; On both sides of the lower end of the stem 2, the tooth wings 3 are in an extended structure backward. The tooth seat 5 is an inverted conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com