Spring pack assembly for torque transmitting device

A spring group and component technology, applied in the direction of spring components, springs, springs/shock absorbers, etc. composed of several springs, can solve problems such as instability of clutch components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

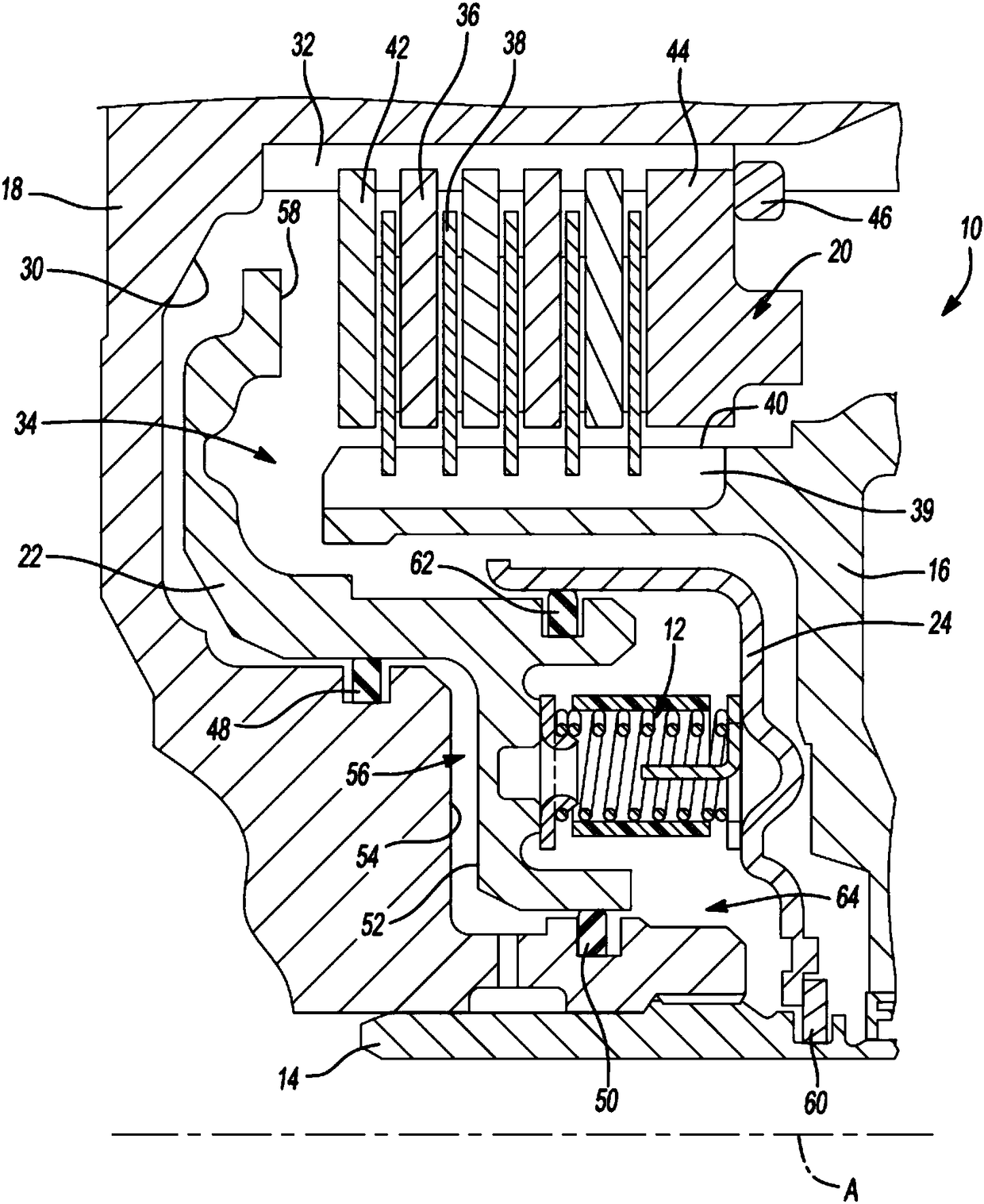

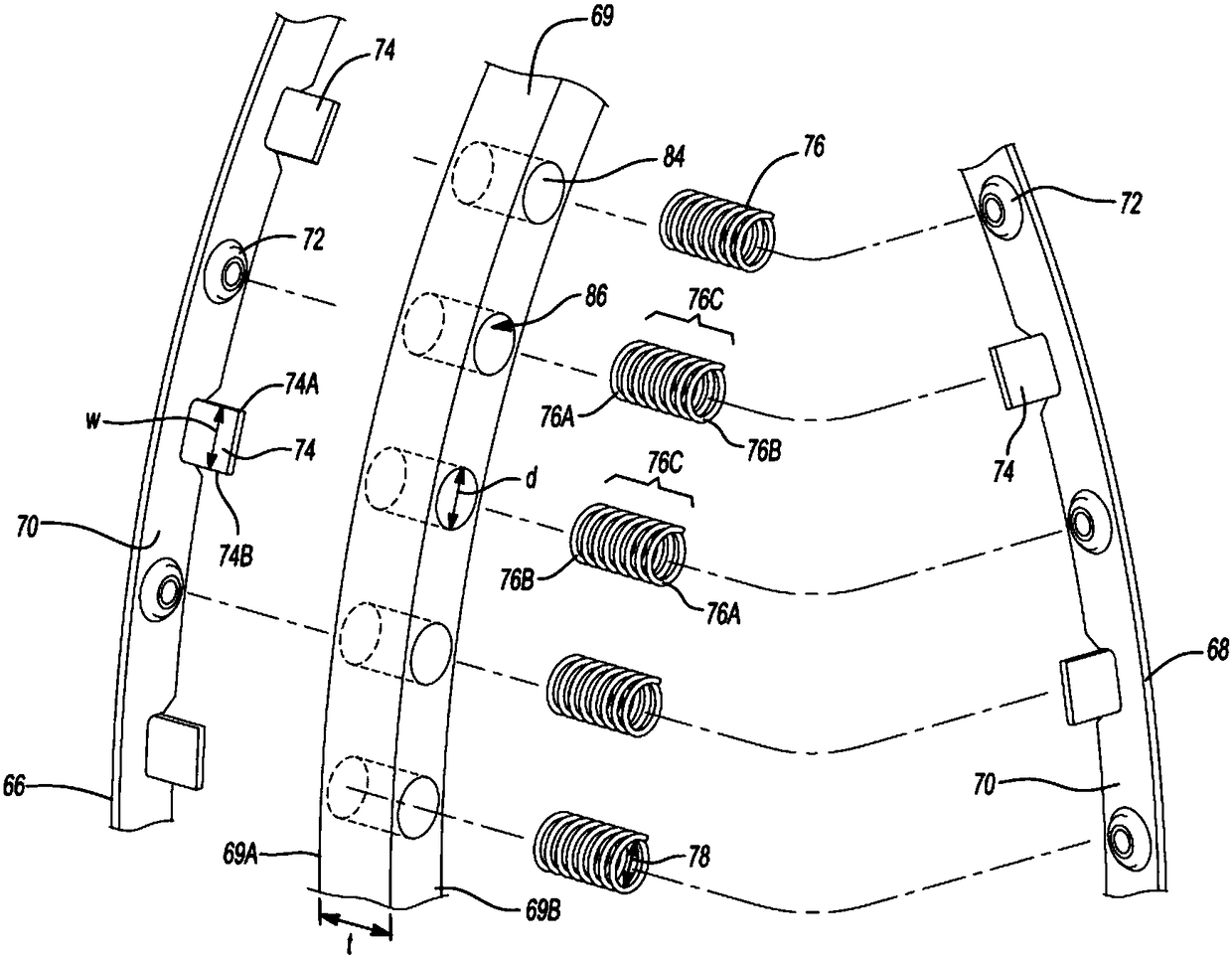

[0023] Referring to the drawings, wherein like reference numerals refer to like parts, figure 1 A cross-sectional view of the torque transmitting device 10 with a return spring pack assembly 12 for a transmission (not shown) of a motor vehicle is shown. The transmission may be a variable diameter pulley or sheave driven continuously variable transmission (CVT), a multi-speed planetary gear set automatic transmission or a manual transmission without departing from the scope of the present invention. The depicted exemplary torque transmitting device 10 is a hydraulically actuated piston multi-plate friction clutch. It should be understood that the torque transmitting device 10 may be a hydraulically actuated piston dog clutch, a cone clutch, a plate clutch or other torque transmitting device having a return spring pack assembly 12 without departing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com