Labview-based control valve performance evaluation system

A technology for evaluating systems and control valves, applied in the direction of general control systems, control/regulation systems, program control, etc., capable of solving problems such as failure performance, wear, and decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

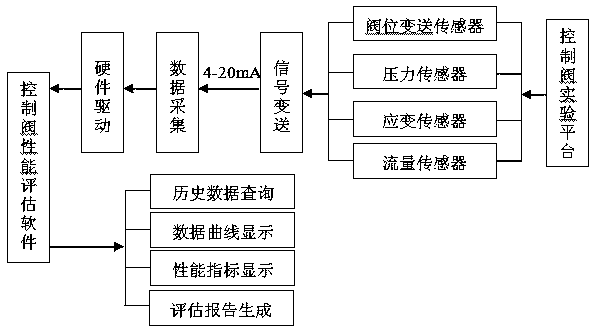

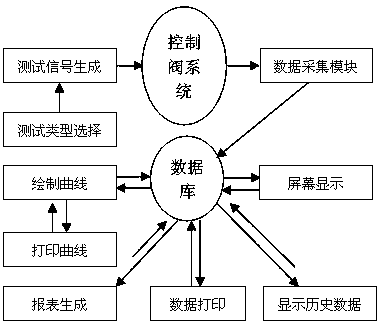

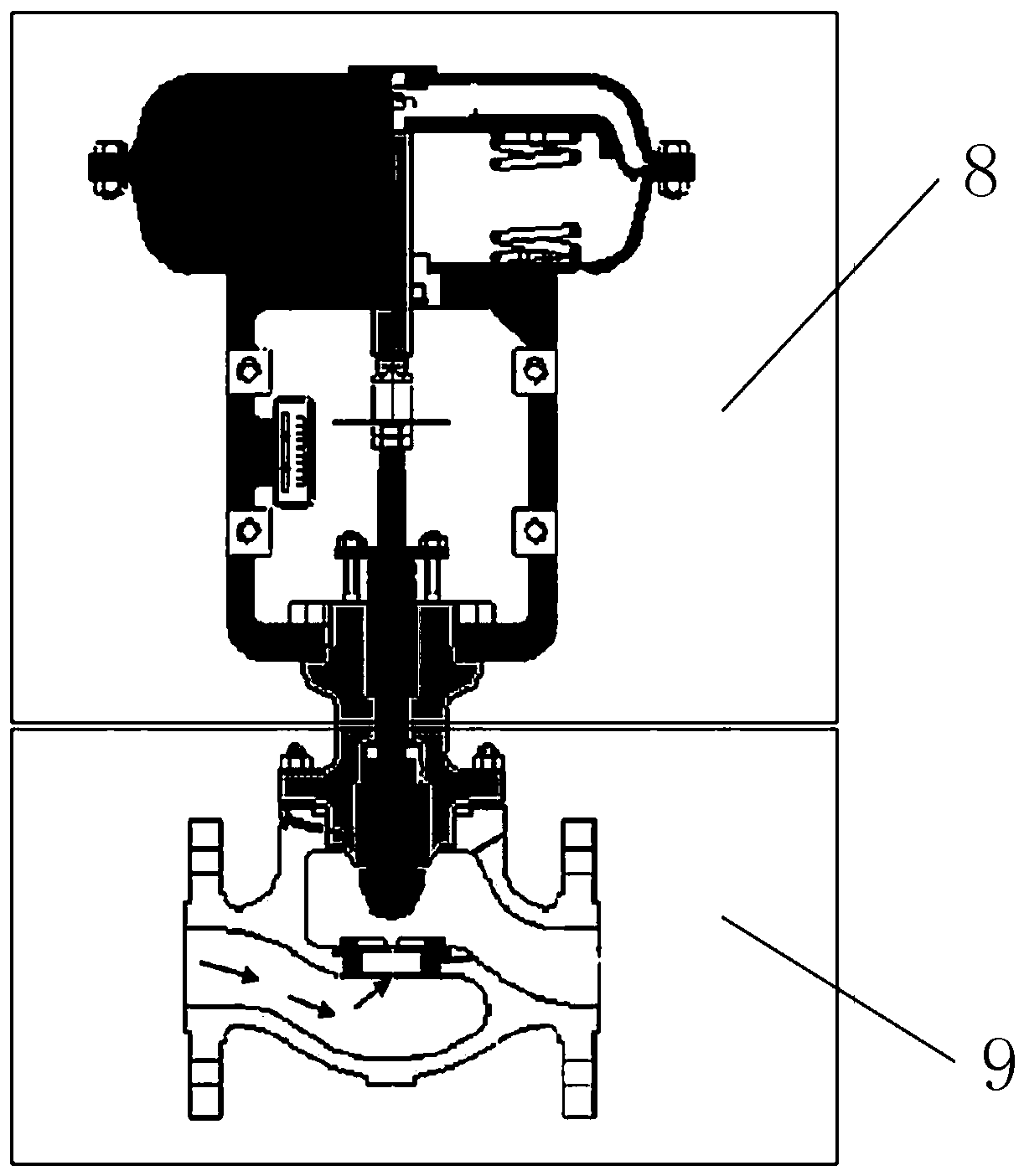

[0016] The control valve performance evaluation system based on Labview of the present invention is composed of a hardware test bench and a host computer program part based on LabVIEW software; the hardware test bench includes a gas circuit system, a circuit system and a liquid circuit system, and the test valve body 9 and The hydraulic system is connected, the membrane actuator 8 is connected to the gas system, and the circuit system is connected through the electric valve positioner and various sensors. The host computer applies excitation signals to the electric valve positioner through different test standards, and embedded in key parts Corresponding sensors collect parameter information and feed it back to the host computer through Ethernet, and the host computer conducts comprehensive analysis on the data.

[0017] The air circuit system of the hardware test bench wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com