Crack detecting robot structure for outer wall surface of buildings and use method of same

A technology of robots and cracks, which is applied in the direction of instruments, manipulators, measuring devices, etc., can solve the problems of inconvenient crack detection and achieve the effect of reducing adsorption force and reducing impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

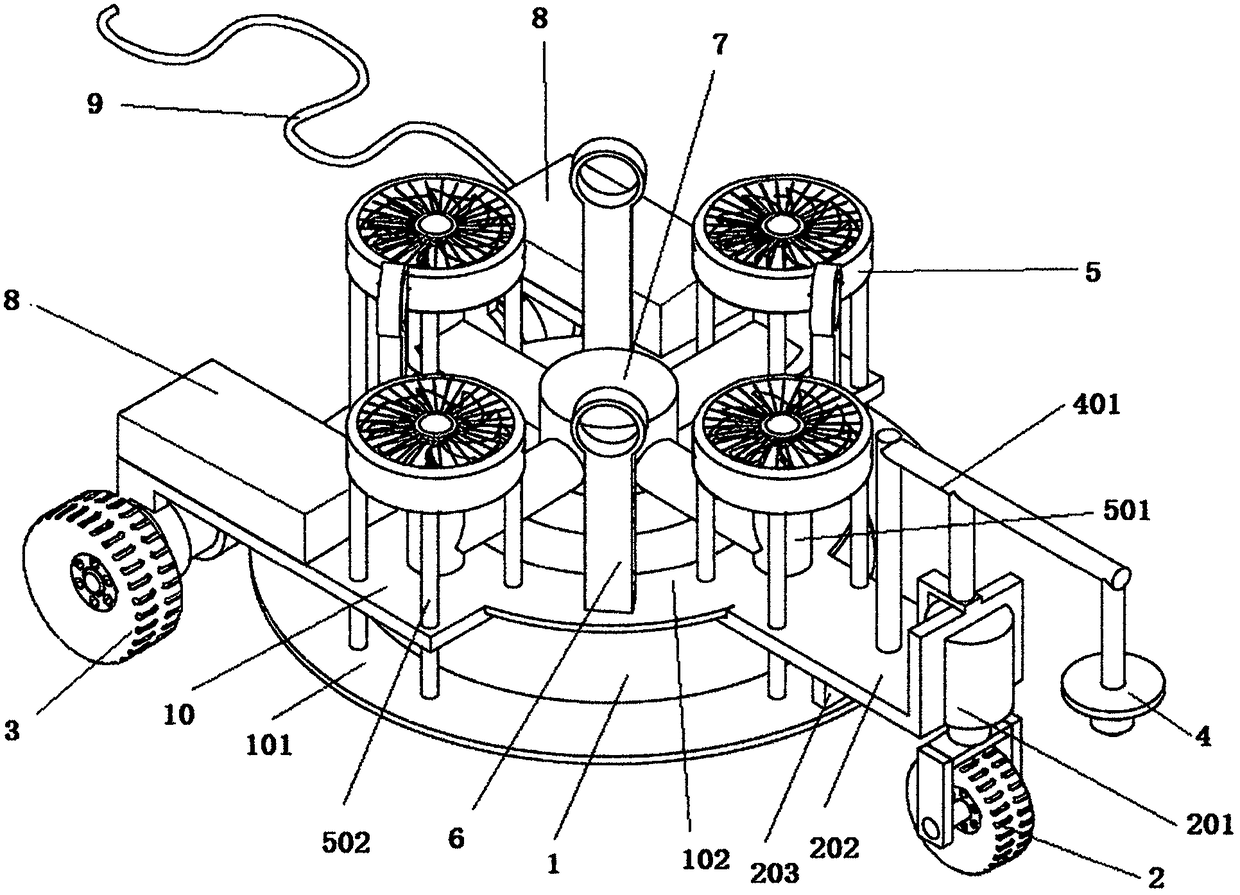

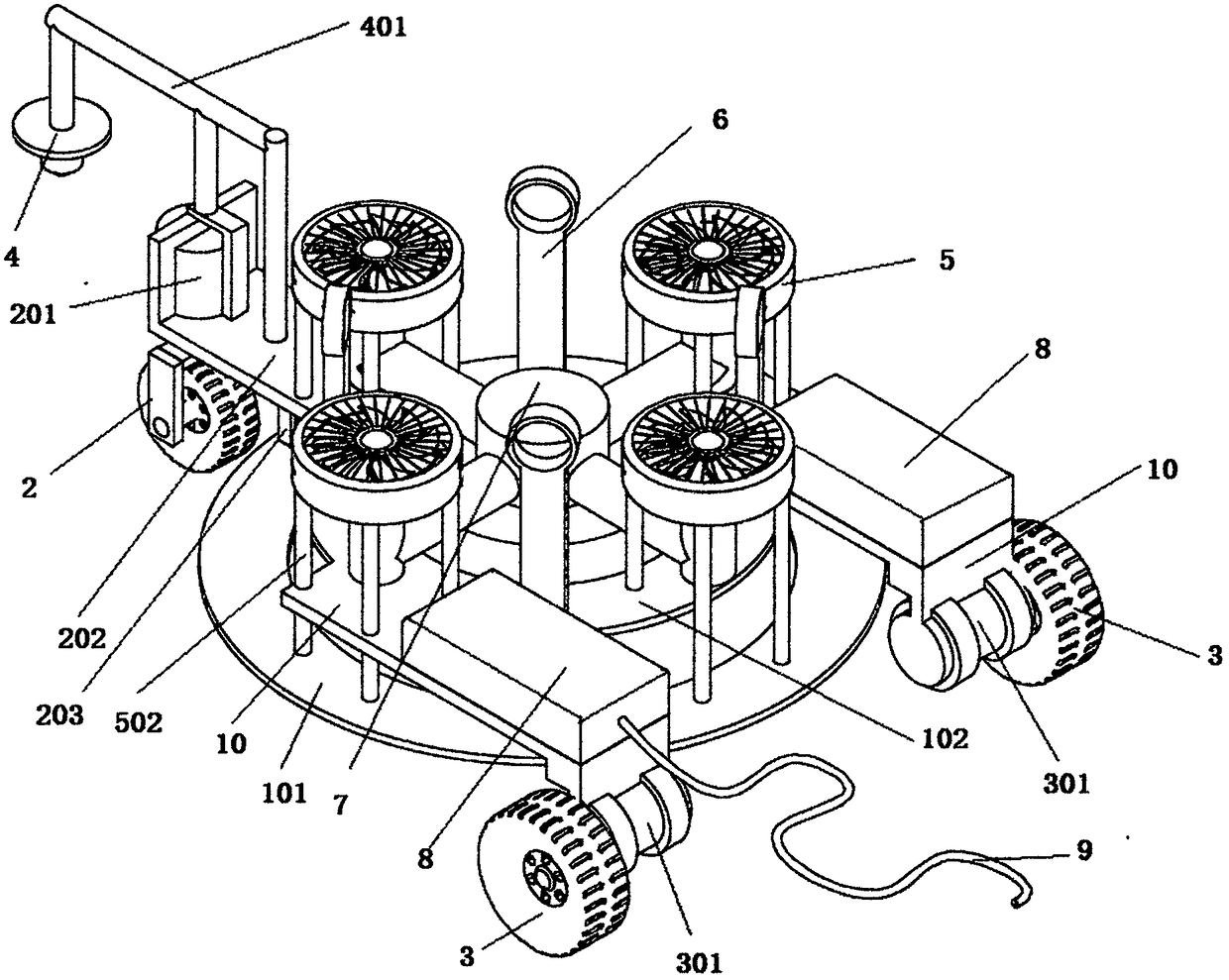

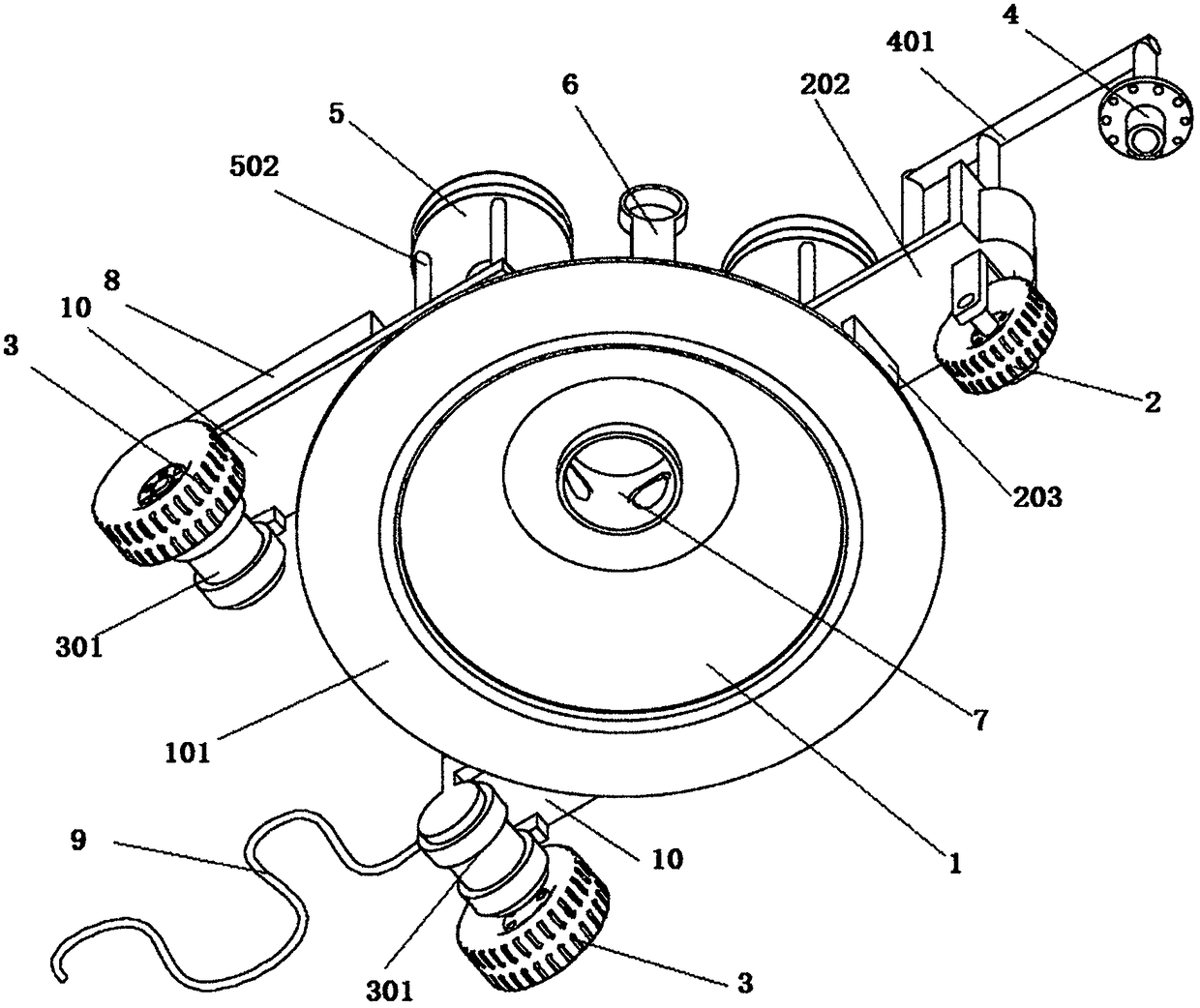

[0026] as attached figure 1 to attach image 3 Shown:

[0027] The present invention provides a crack detection robot structure on the exterior wall of a building and its use method, comprising a wind collecting hood 1, a circular ring mounting plate 101, a circular ring support plate 102, a steering wheel 2, a steering motor 201, and a steering wheel mounting plate 202 , reinforced support plate 203, rear wheel 3, rear wheel drive motor 301, camera 4, camera bracket 401, suction fan 5, ventilation duct 501, fan bracket 502, buffer plate 6, central air cylinder 7, component box 8, power supply line 9 and the rear wheel mounting plate 10, a central air cylinder 7 is vertically connected to the top end surface of the wind collecting hood 1; the four supporting rods of the fan bracket 502 are divided into two groups and respectively supported and fixed on the ring mounting plate 101 and the ring support plate 102, and the fan bracket 502 is arranged in four places in an annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com