A Software Reliability Evaluation Method for Electromechanical Products Based on Environmental Fault Injection

A fault injection, electromechanical product technology, applied in software testing/debugging, electrical digital data processing, instruments, etc., can solve the problem that there is no fault reliability evaluation method based on external environment, achieve accurate reliability evaluation, ingenious design, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

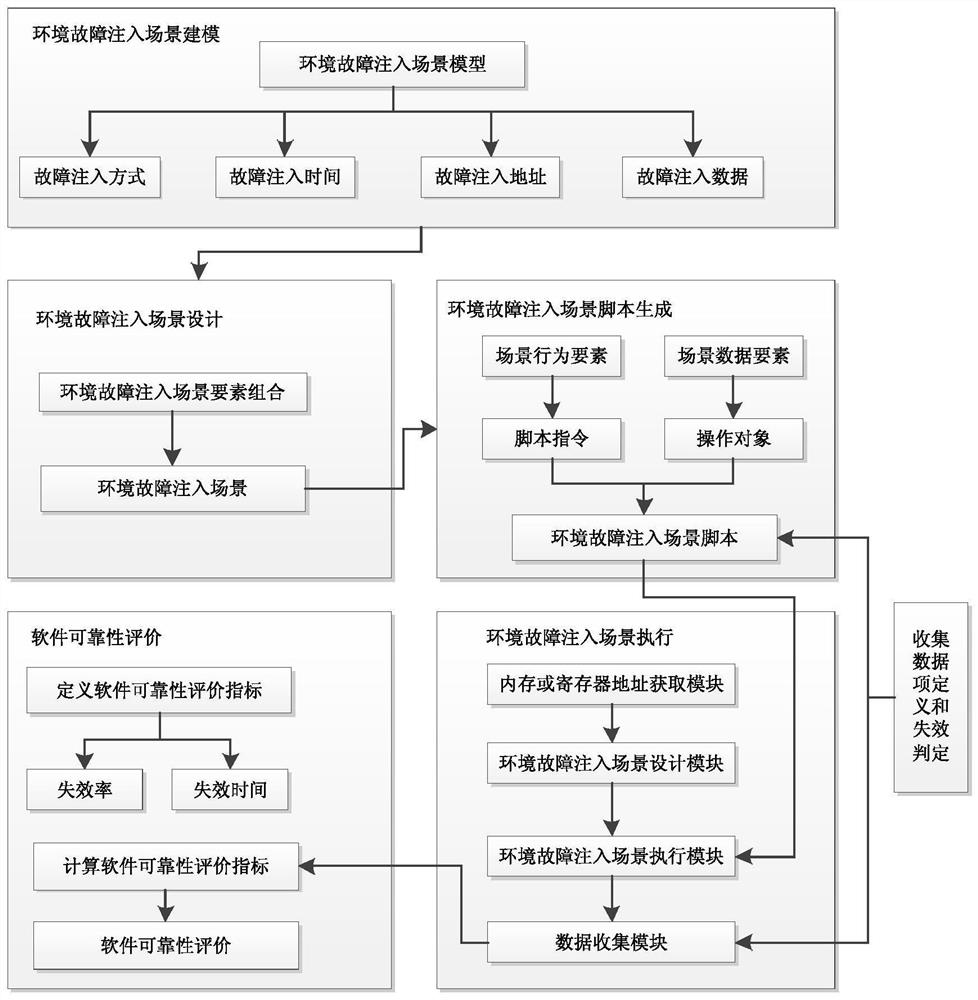

[0035] A method for evaluating the reliability of electromechanical product software based on environmental fault injection, is characterized in that, comprises the following steps:

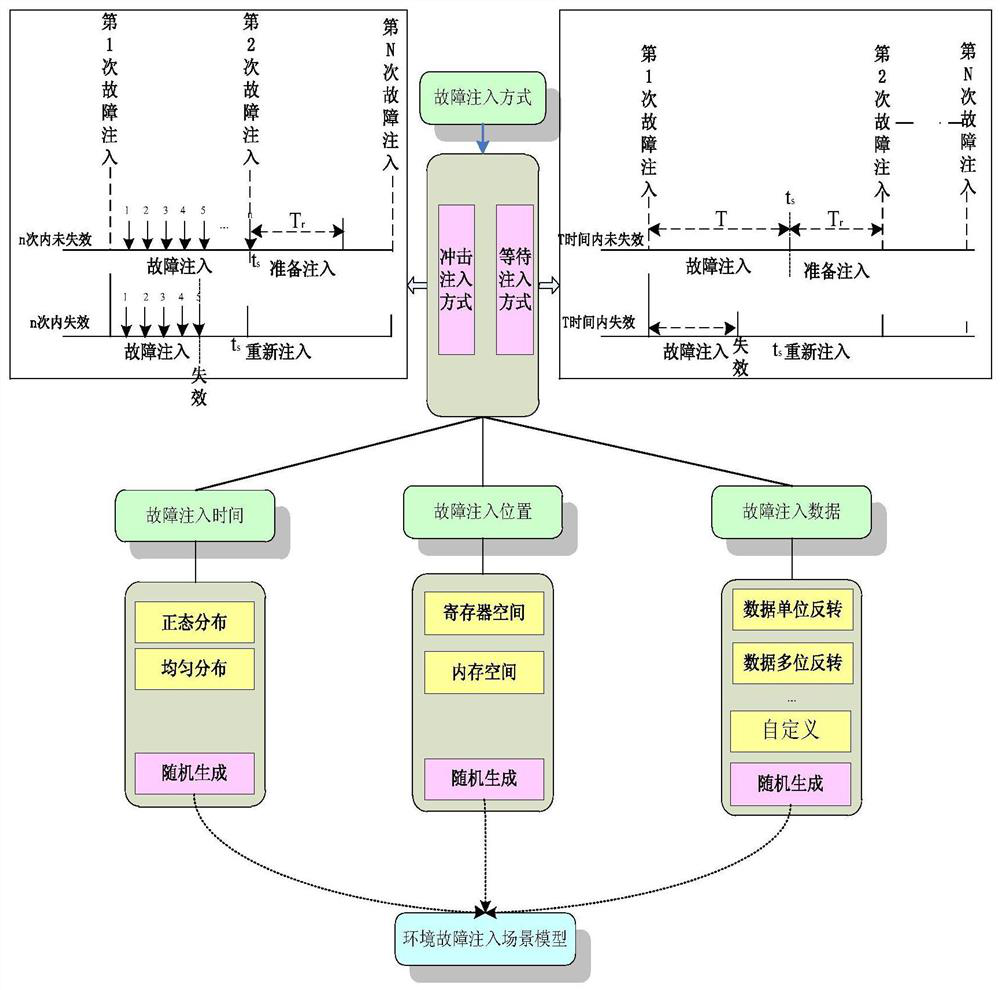

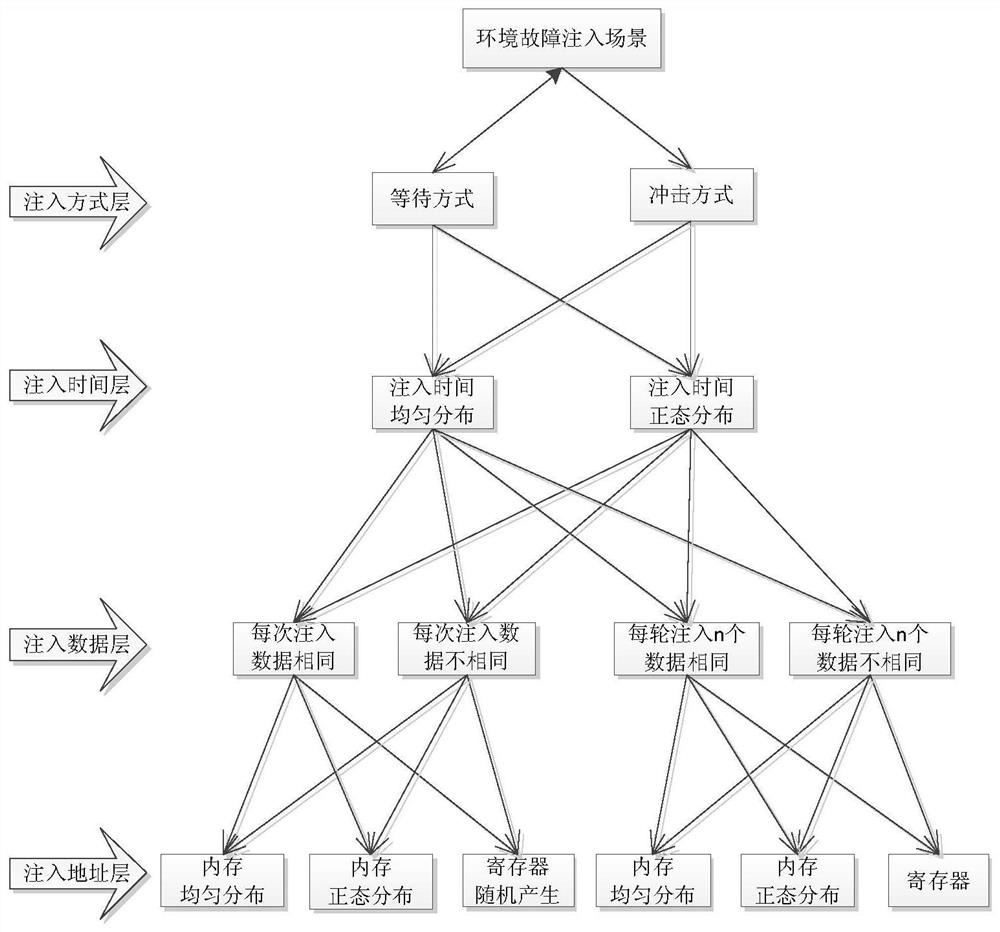

[0036]The first step is to determine the four scenario elements of environmental fault injection scenario modeling. Specifically, the environmental fault injection scenario model elements are represented by 4-tuples {IB, IT, IL, ID}; specifically include the fault injection method IB, Inject Behavior , fault injection time IT, Inject Time, fault injection location IL, Inject Location, fault injection data ID, Inject Data, wherein, the fault injection mode includes impact mode and waiting mode; the fault injection time is generated by uniform distribution or normal distribution; Fault injection locations include memory and registers, and the specific generation method is uniform distribution or normal distribution; fault injection data is automatically generated by using fault data generation rules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com