Metal bipolar plate flow field configuration with high distribution consistency

A metal bipolar plate, consistent technology, applied in the direction of fuel cells, electrochemical generators, electrical components, etc., can solve the problems affecting the operation stability of fuel cells, small gas inlet and outlet areas, easy to generate local turbulence, etc., to achieve Avoid uneven gas distribution, improve gas distribution, and avoid local turbulent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

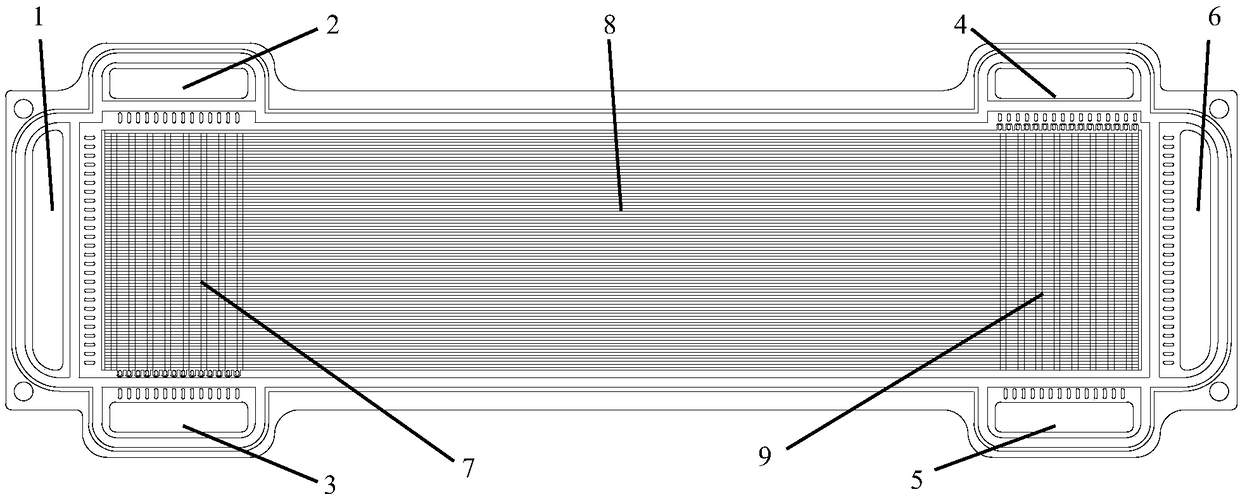

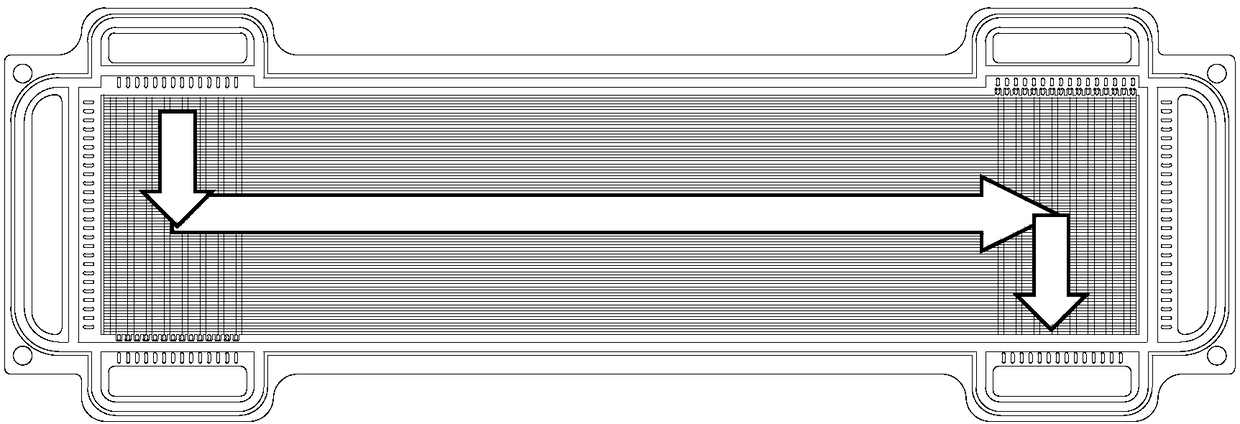

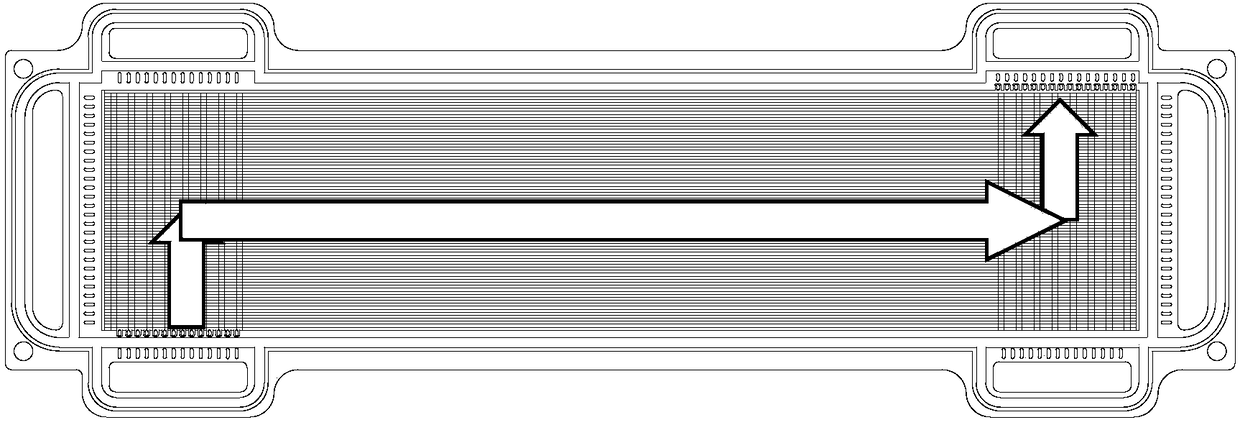

[0060] A metal bipolar plate flow field configuration with high distribution consistency, such as figure 1 As shown, it is formed by contact welding of the B side of the anode plate and the B side of the cathode plate. Both the anode plate and the cathode plate include a first fluid distribution area 7, a straight channel area 8 and a second fluid distribution area 9. , the coolant all flow through the first fluid distribution area 7, the straight channel area 8 and the second fluid distribution area 9 in sequence; A fluid channel is opened on the surface A, and a water passage is provided on the contact surface formed by the contact between the B surface of the anode plate and the B surface of the cathode plate, and the coolant flows in the water passage.

[0061] The anode plate and the cathode plate are located in the straight channel area 8. The fluid tank and the water passage are all linear. The inlet 3 of the combustion gas, the inlet 1 of the oxidant, and the inlet 2 o...

Embodiment 2

[0065] This embodiment is the same as Embodiment 1, the difference is that the thickness of the stainless steel plate is 0.2mm, and the A face of the anode plate is located in the fluid tank of the first fluid distribution area and the second fluid distribution area. Cylindrical protrusions on the A side of the cathode plate, the A side of the cathode plate is located in the fluid tank of the first fluid distribution area and the second fluid distribution area, and several cylindrical protrusions perpendicular to the A side of the cathode plate are provided; the cylindrical protrusions To enable the coolant to flow from the water channel into the hollow structure inside the protrusion. Wherein, the diameter of the cylindrical protrusion is 5mm, the height is 0.4mm, and the radius of the cross section of the water passage connecting the cylindrical protrusion is 2mm, such as Figure 5 shown. It can effectively improve the fluid distribution and reduce the fluid resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com