Vertical rod press folding mechanism of scooter and scooter

A technology for folding mechanisms and scooters, which is applied to foldable bicycles, steering mechanisms, motor vehicles, etc., can solve the problems of inconvenient folding of scooters, and achieve the effects of ingenious design, safe and reliable structure, and convenient storage and carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

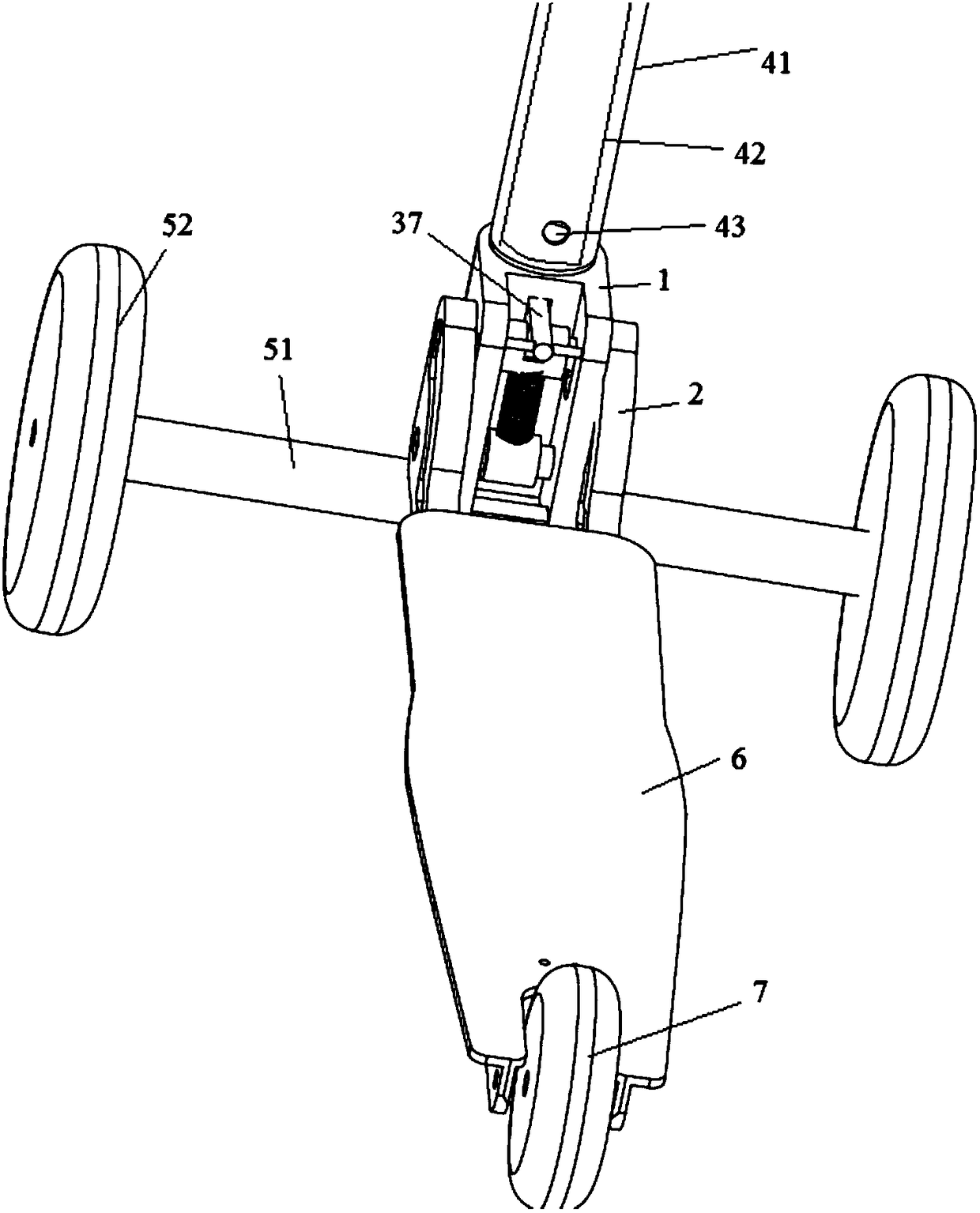

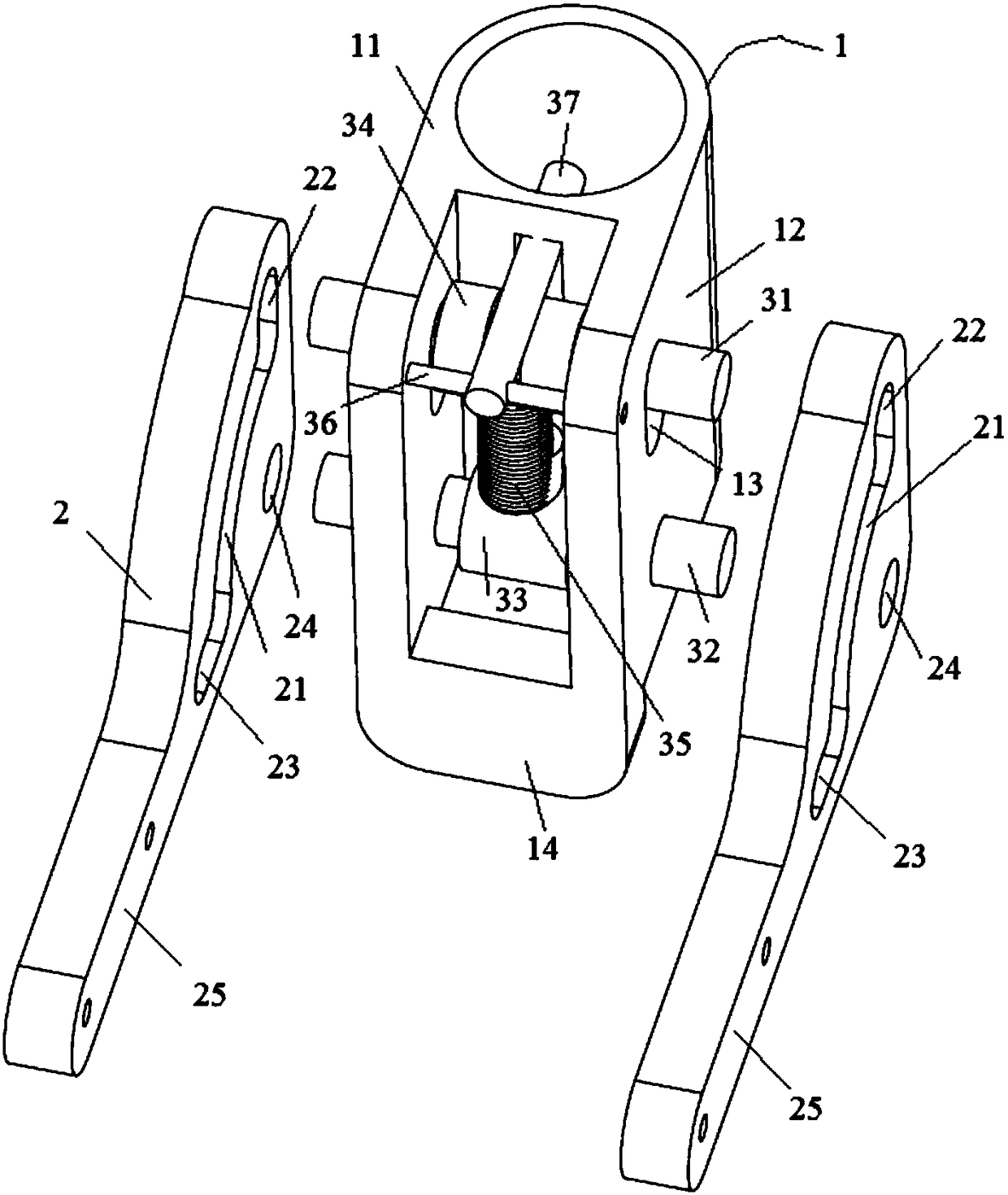

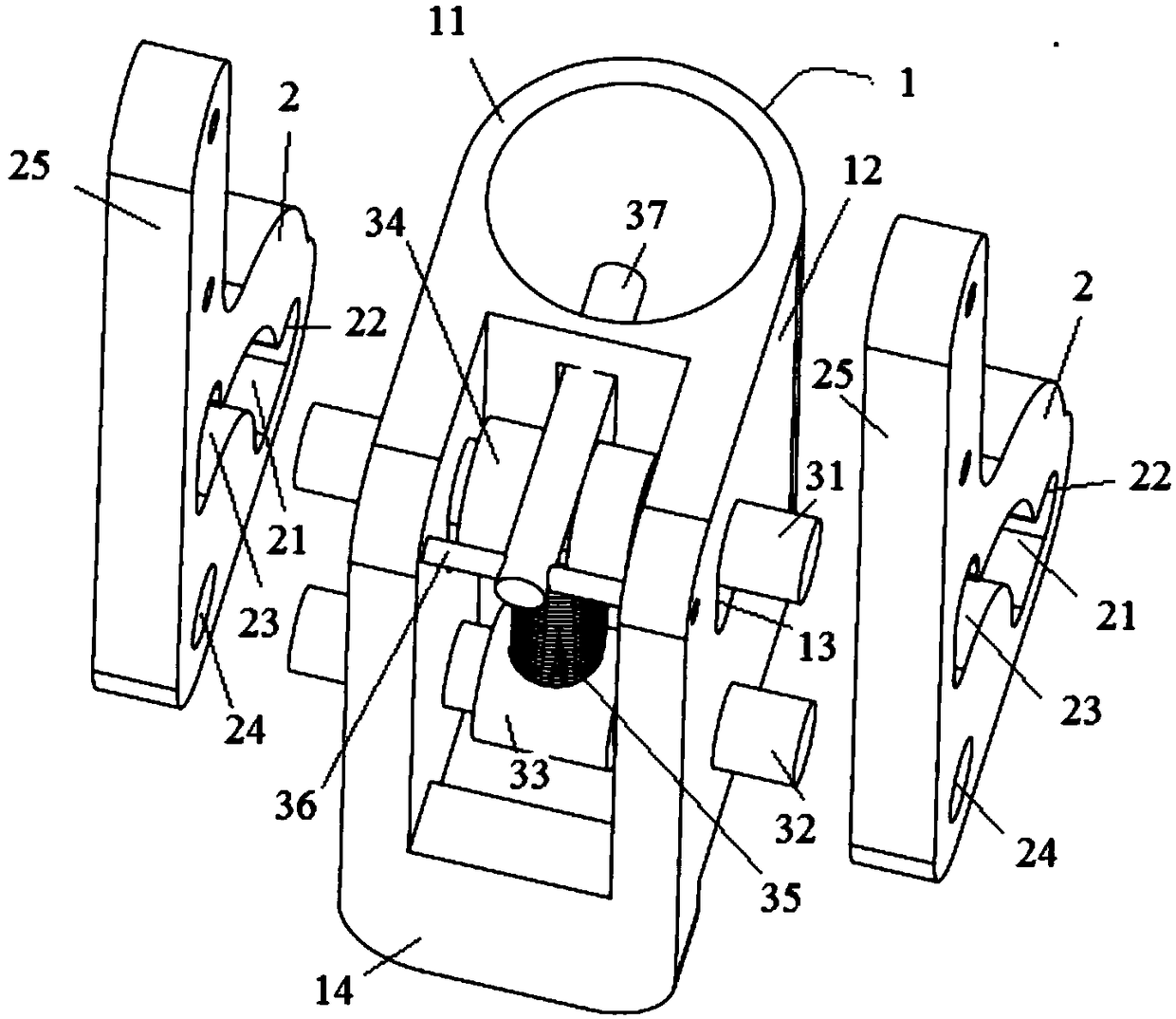

[0026] like Figures 1 to 9 As shown, the present invention discloses a vertical rod pressing and folding mechanism of a scooter, including a vertical rod 4, a bowl assembly 1 and a connecting piece 2, and the bowl assembly 1 includes a sleeve main body 11 and a fixed connection with the sleeve. The wing plate 12, the wing plate 12 is hinged with the connecting member 2 through the rotating pin 32, the connecting member 2 is provided with a sliding guide rail, and the two ends of the sliding guide rail are respectively provided with an unfolding groove 22 and a folding groove 23. The wing plate 12 is also provided with a limit pin 31 adapted to the sliding guide rail, the wing plate 12 is provided with a strip-shaped folding hole 13, and the limit pin 31 is installed in the strip-shaped folding hole 13, so The limiting pin 31 is provided with a return spring 35, the bowl assembly 1 further includes a folding pressure rod 37, one end of the folding pressure rod 37 is hinged wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com