Transportation tray vehicle for flight cases

A carrier car and air box technology, which is applied in the directions of transporting objects, transportation and packaging, and vehicles for freight transportation, etc., can solve the problems of low ease of use, cumbersome operation steps for positioning the air box, and poor positioning and fixing effect of the air box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

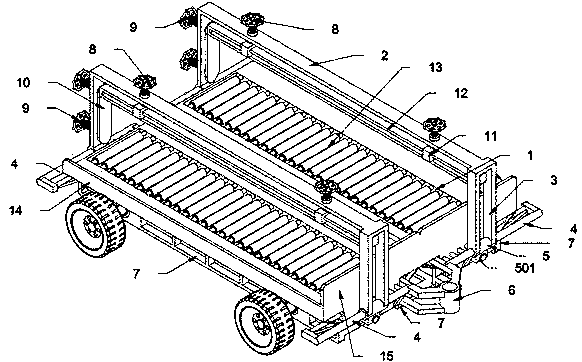

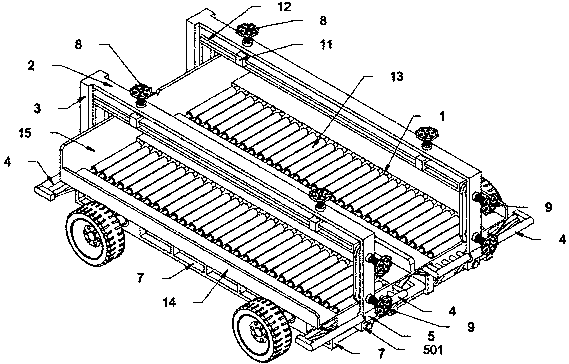

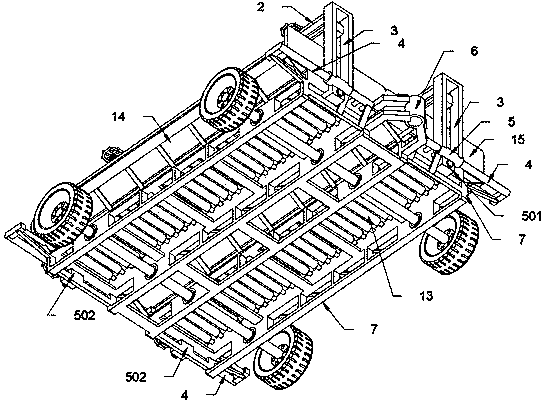

[0038] as attached figure 1 To attach Figure 8 Shown:

[0039] The present invention provides an air box transportation bracket vehicle, which includes a bracket body 1, a frame connecting support plate 101, a positioning frame 2, a front end support plate 3 of the positioning frame, a supporting sliding shaft 4, a sliding sleeve 5, and a sliding sleeve positioning plate 501, Positioning block 502, socket sleeve 6, supporting leg frame 7, jacking screw 8, pinching screw 9, pinching plate 10, jacking frame sliding sleeve 11, jacking frame 12, roller 13, limit side plate 14 And the front end top plate 15, the bracket car as a whole is formed by welding the two bracket bodies 1 on the left and right, and the bottoms of the two bracket bodies 1 are symmetrically supported and welded with two support leg frames 7, which are located on the inner side and adjacent to each other. A row of connecting plates are arranged equidistantly between the two supporting leg frames 7; the peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com