A kind of livestock and poultry breeding manure automatic treatment fermentation facility

An automatic treatment, livestock and poultry breeding technology, applied in the fields of animal husbandry wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

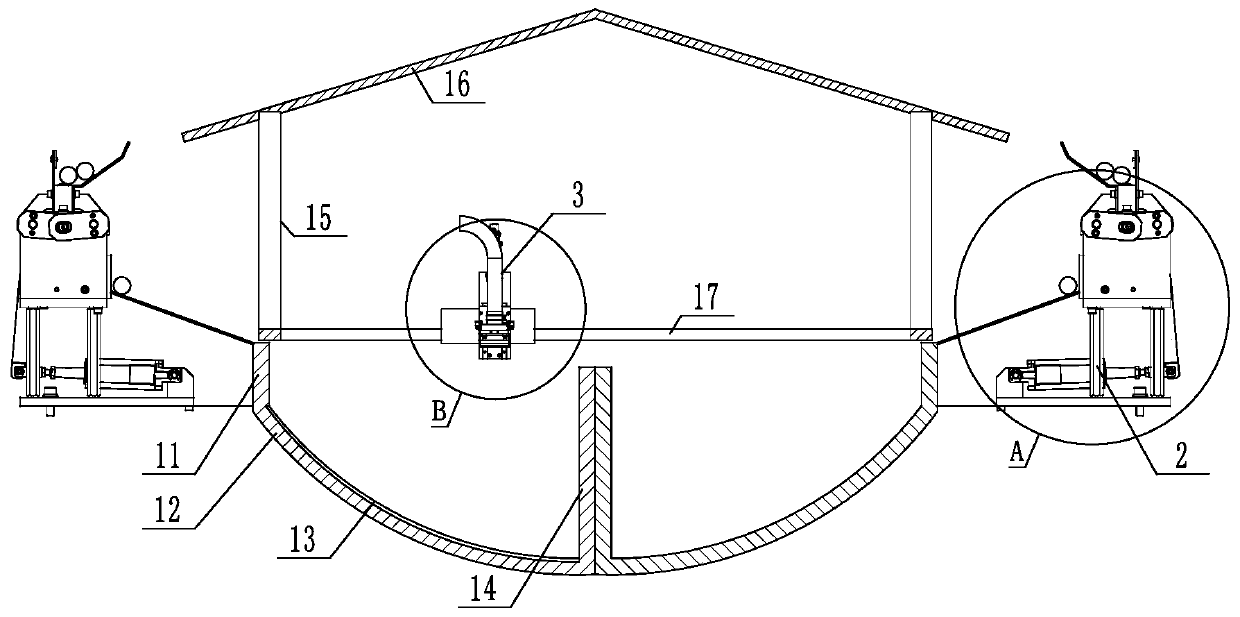

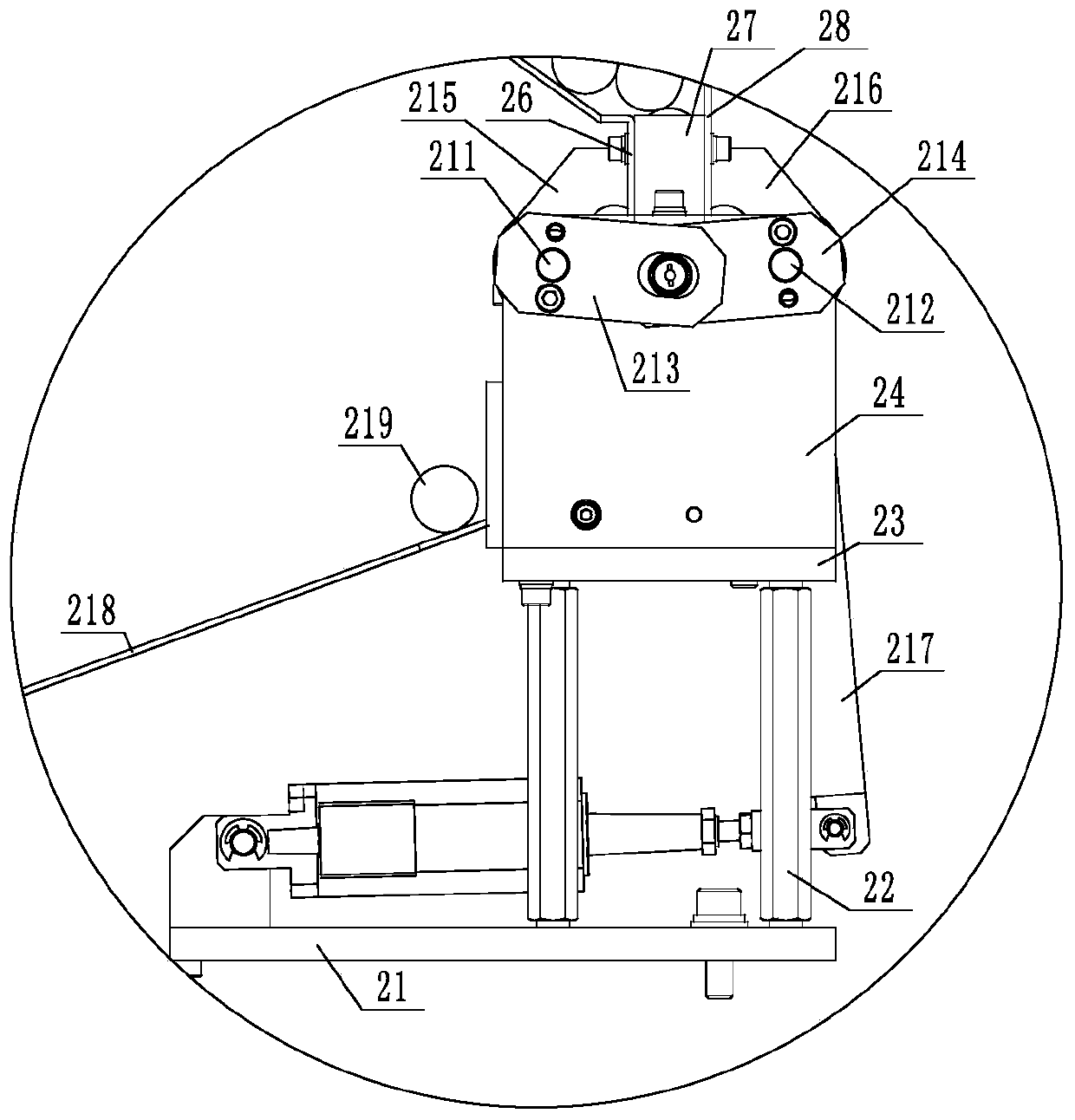

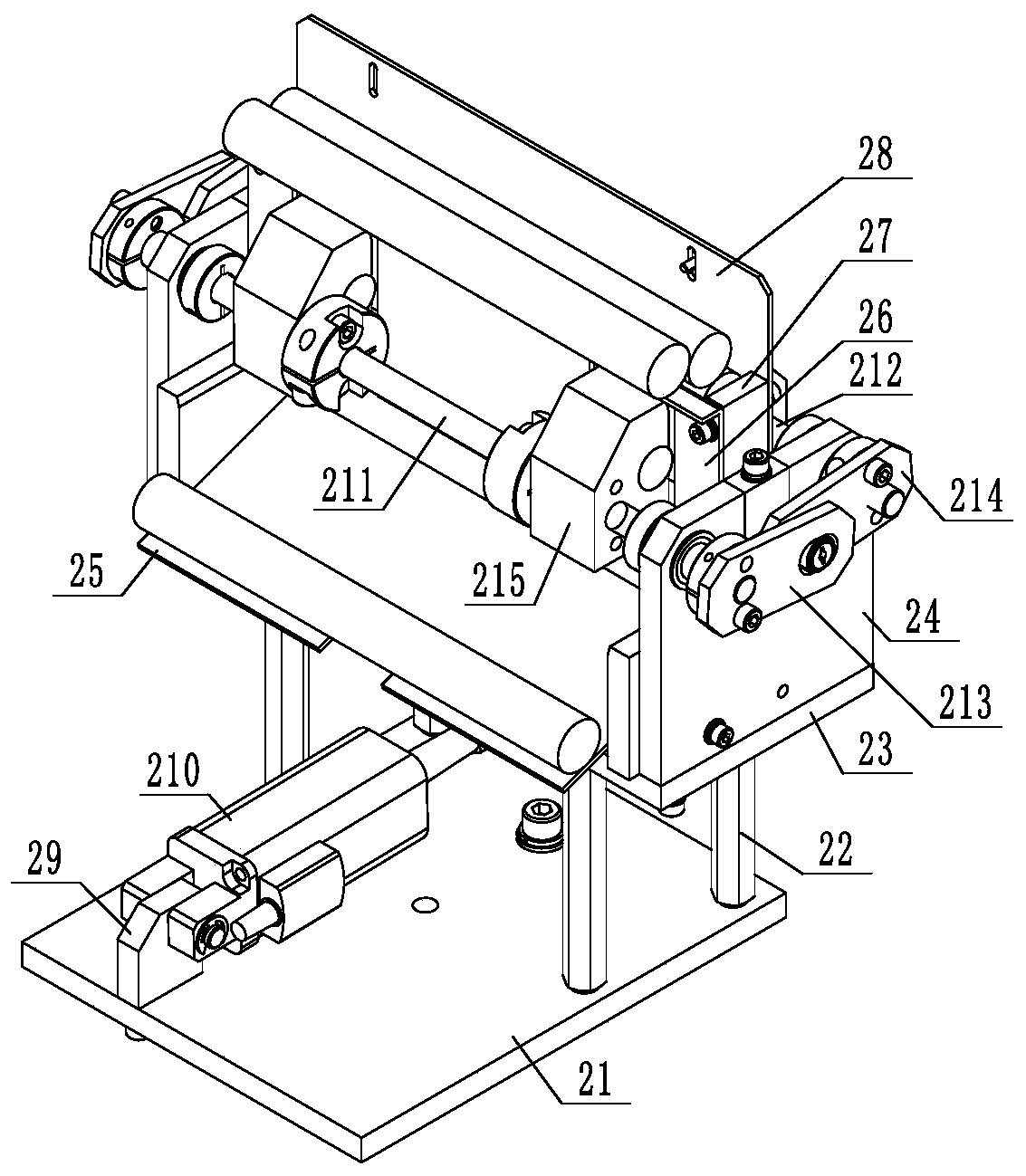

[0029] Such as figure 1 As shown, a kind of livestock and poultry breeding excrement automatic treatment fermentation facility comprises a first fermentation tank and a second fermentation tank composed of an outer plate 11, a curved plate 12 and an inner plate 14, the first fermentation tank and the second fermentation tank It can be located below the cement floor, and the middle part of the first fermentation tank and the second fermentation tank is separated by setting an inner plate,

[0030] The arc-shaped plate is provided with a plurality of diversion grooves 13 arranged in parallel.

[0031] A guide rod 17 is erected on both sides of the fermentation tank assembly composed of the first fermentation tank and the second fermentation tank, and the dung water injection mechanism 3 is slidingly fitted on the guide rod 17,

[0032] The ends of the guide rods are provided with support rods 15 , and ceilings 16 are installed on the upper sides of a plurality of the support ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap