Detergent feeding device with siphon structure and washing machine

A detergent dispensing and detergent box technology, applied in the field of washing machines, can solve the problems of complicated assembly of a siphon structure, inaccurate positioning of the siphon structure, complicated structure of a siphon device, etc., and achieves material saving, is not easy to loosen, and has an effective siphon effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

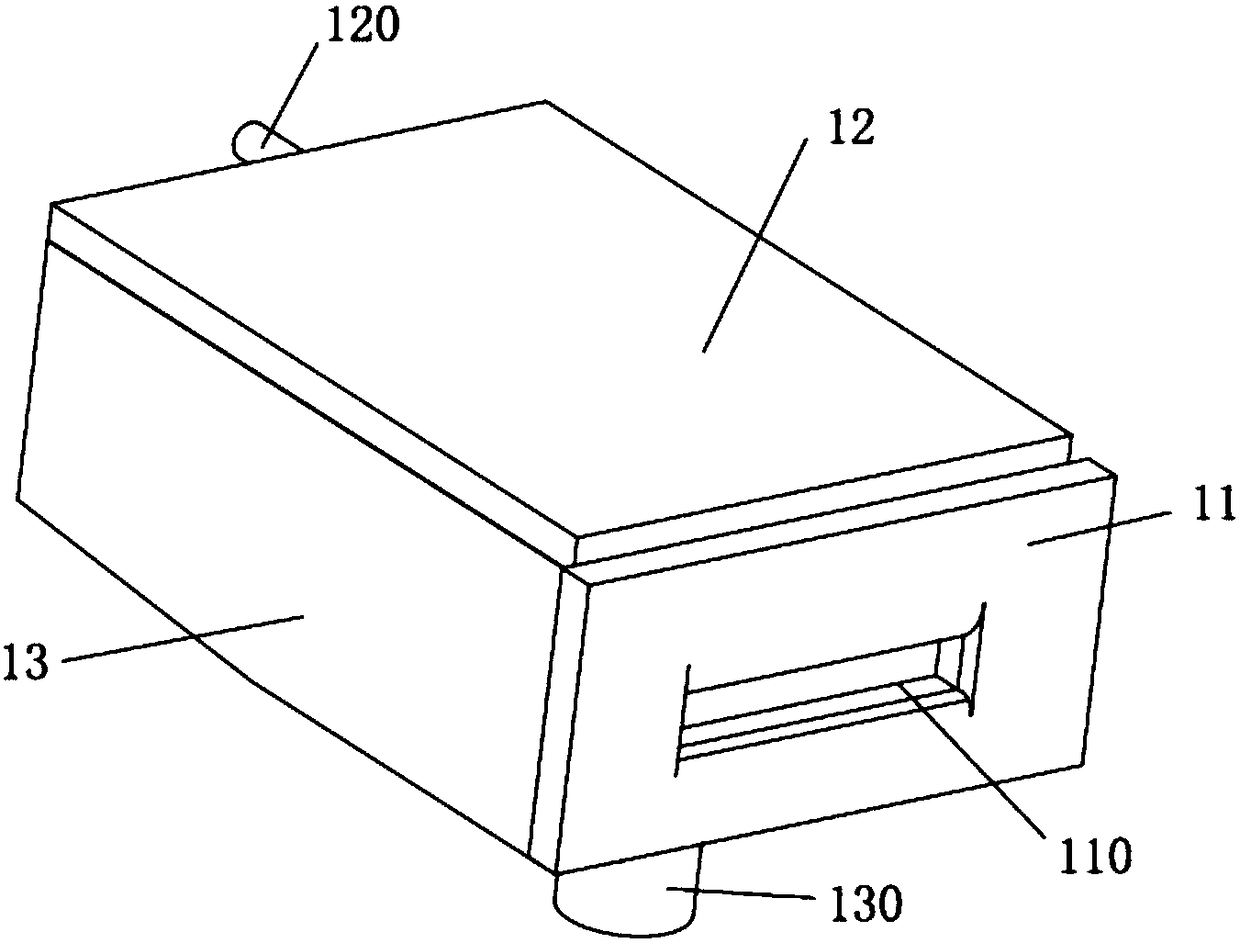

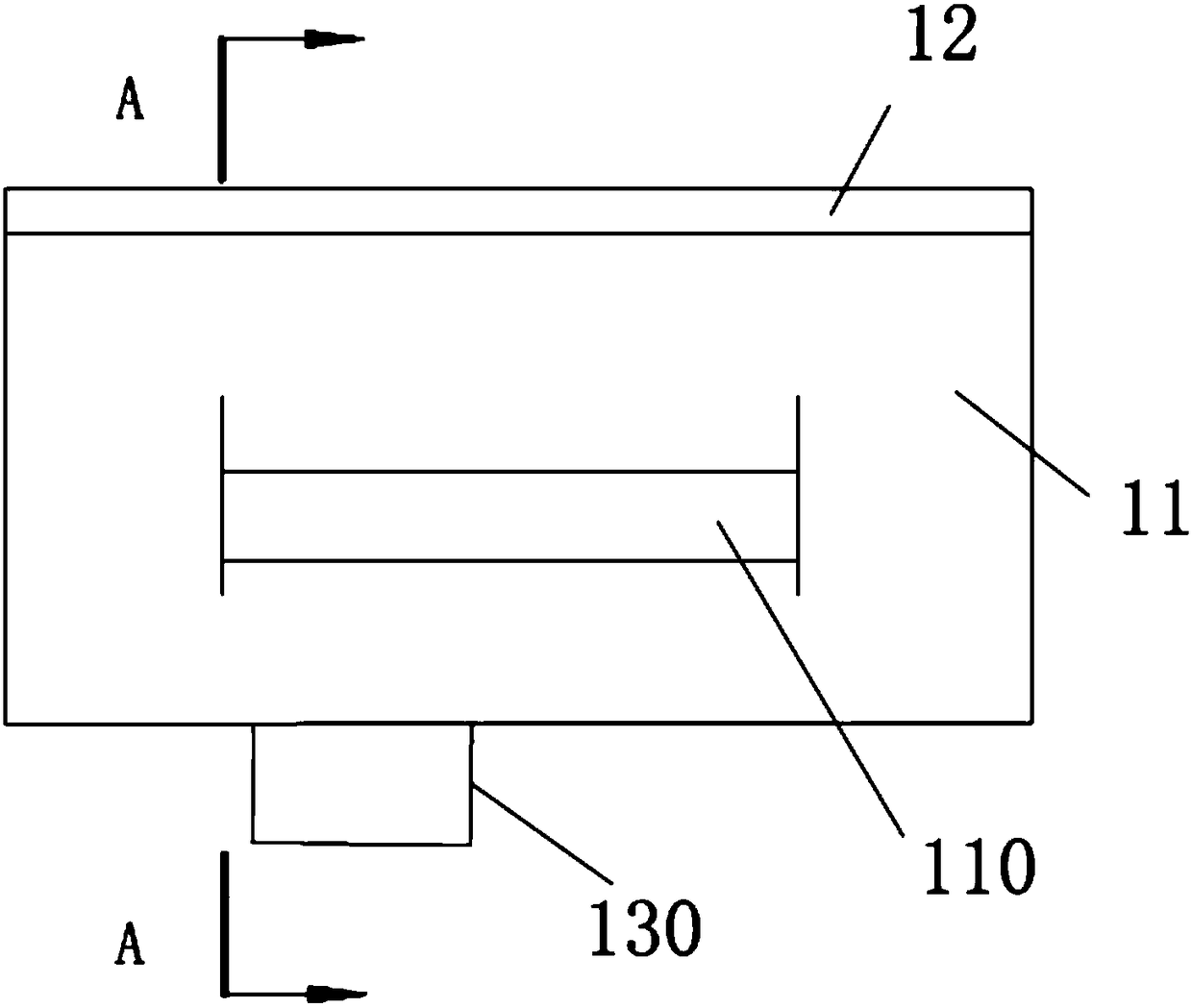

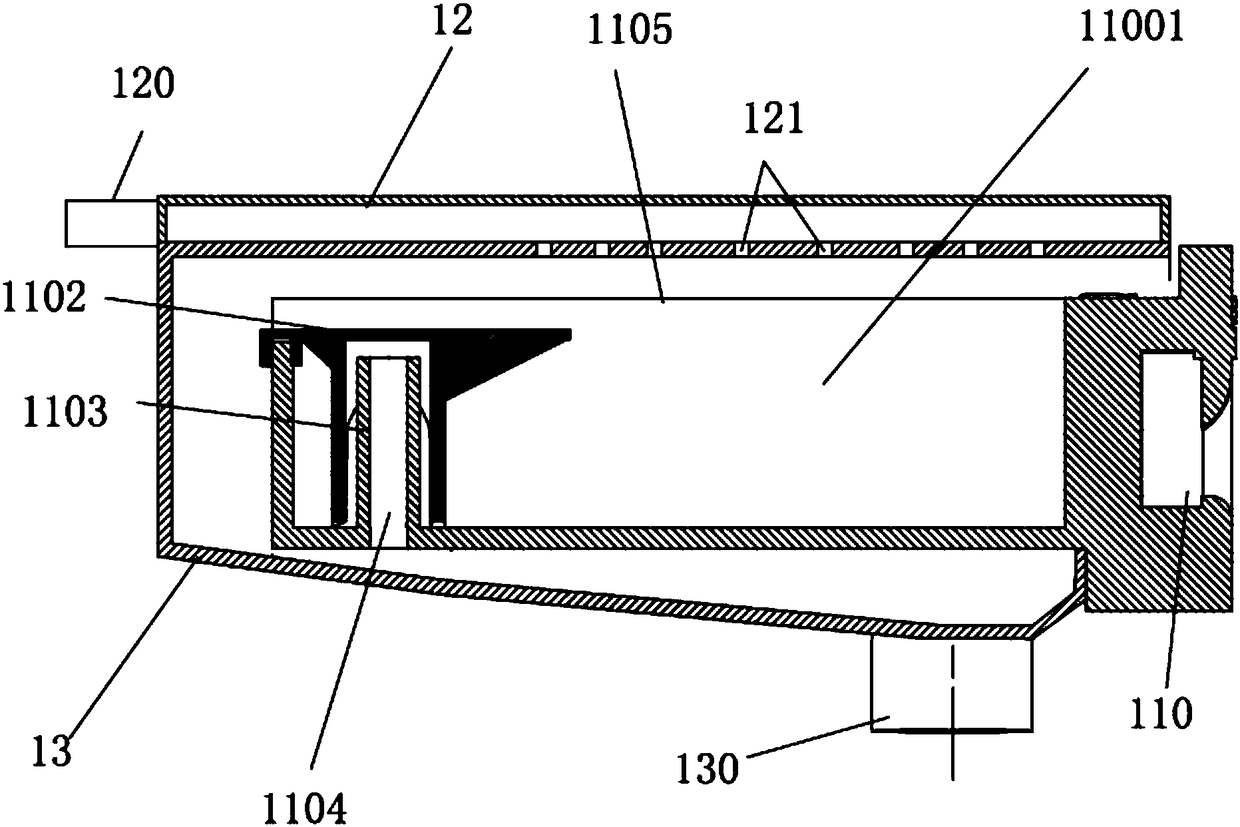

[0057] A detergent dispensing device with a siphon structure, comprising a detergent box 11 with a handle 110, the detergent box 11 is divided into three detergent or additive dispensing boxes, namely: softener dispensing box 11001, detergent dispensing box 11002, pre-wash delivery box 11003.

[0058] A siphon structure is provided in the softener dispensing box 11001, and the siphon structure includes a siphon column 1103 with a siphon hole 1104 and a siphon cap 1102 covering the siphon column 1103;

[0059] The bottom of the siphon cap 1102 has a part with an interference fit with the siphon column 1103. The siphon column 1103 and the siphon cap 1102 have an interference fit and form a flow channel A. The flow channel A communicates with the siphon hole 1104, and the liquid passes through the flow channel A and the siphon hole in turn. 1104 into the washing tub;

[0060] The rear side end of the siphon cap 1102 has a slot 1102a that engages with the rear wall of the liquid ...

Embodiment 2

[0089] The difference between this embodiment and Embodiment 1 is that: the left and right side edges of the top of the siphon cap 1102 are provided with a plurality of protrusions distributed at intervals, and the two side walls 1105 of the liquid detergent dispensing box body are correspondingly provided with a plurality of grooves 1105a, The groove 1105a engages with the protrusion correspondingly, and fixes the side 1102c of the siphon cap 1102 with the side wall 1105 of the liquid detergent dispensing box.

[0090]The siphon cap 1102 and the body of the liquid detergent box are made of materials with a certain degree of elasticity. During the installation process, only the top of the siphon cap 1102 needs to be pressed, and the side 1102c of the siphon cap 1102 and the side of the softener dispensing box 11001 are used. The wall 1105 itself is deformed and pressed down. When the side 1102c of the siphon cap 1102 reaches the groove 1105a of the side wall 1105, both of them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com