Reserved hole forming composite pattern plate of shear wall used for outrigger, shear wall, reserved hole plugging block and method thereof

A technology of reserving openings and combining formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc. It can solve the problems of falling objects from high altitude and troublesome installation of external formwork, so as to prevent falling objects from high altitude , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

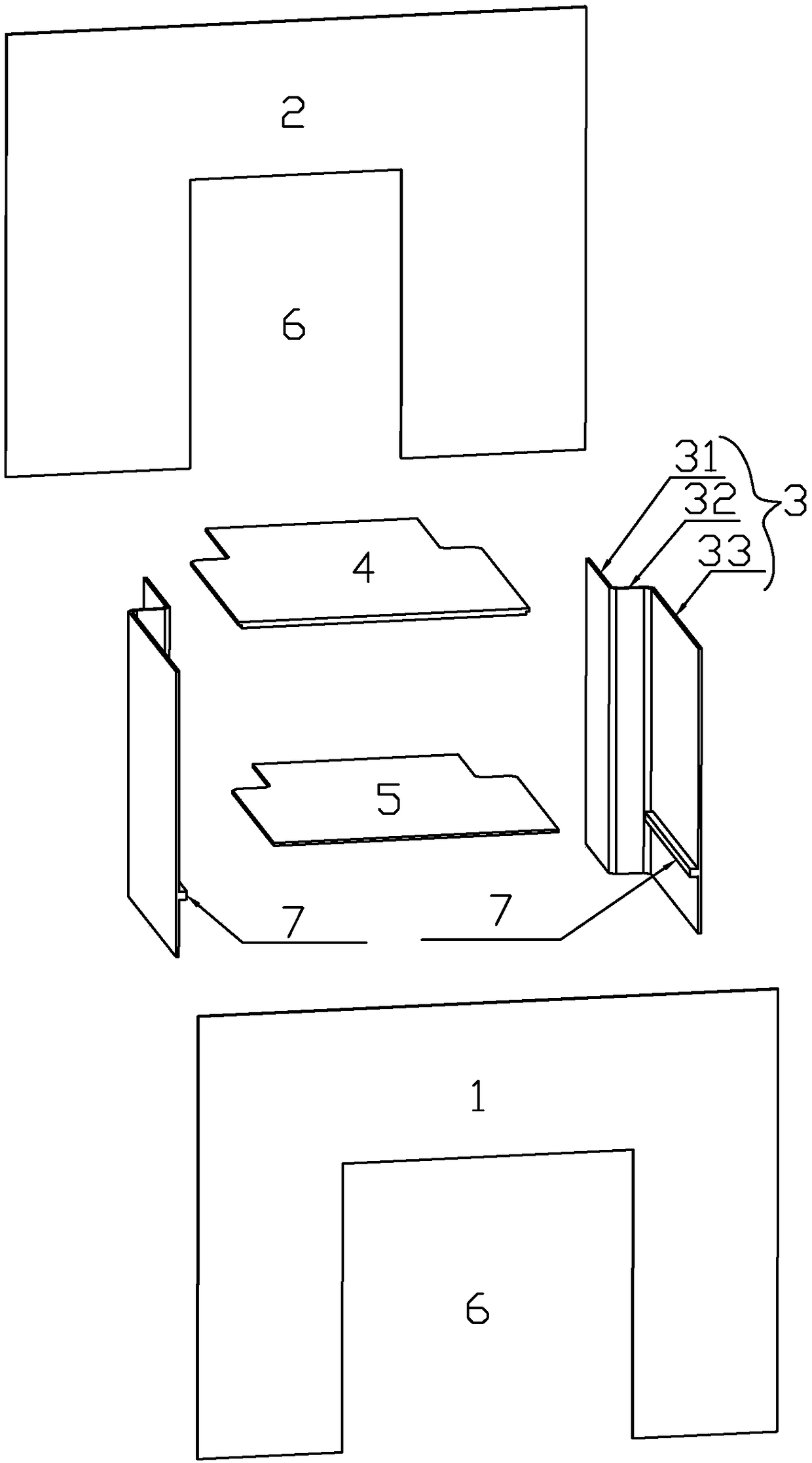

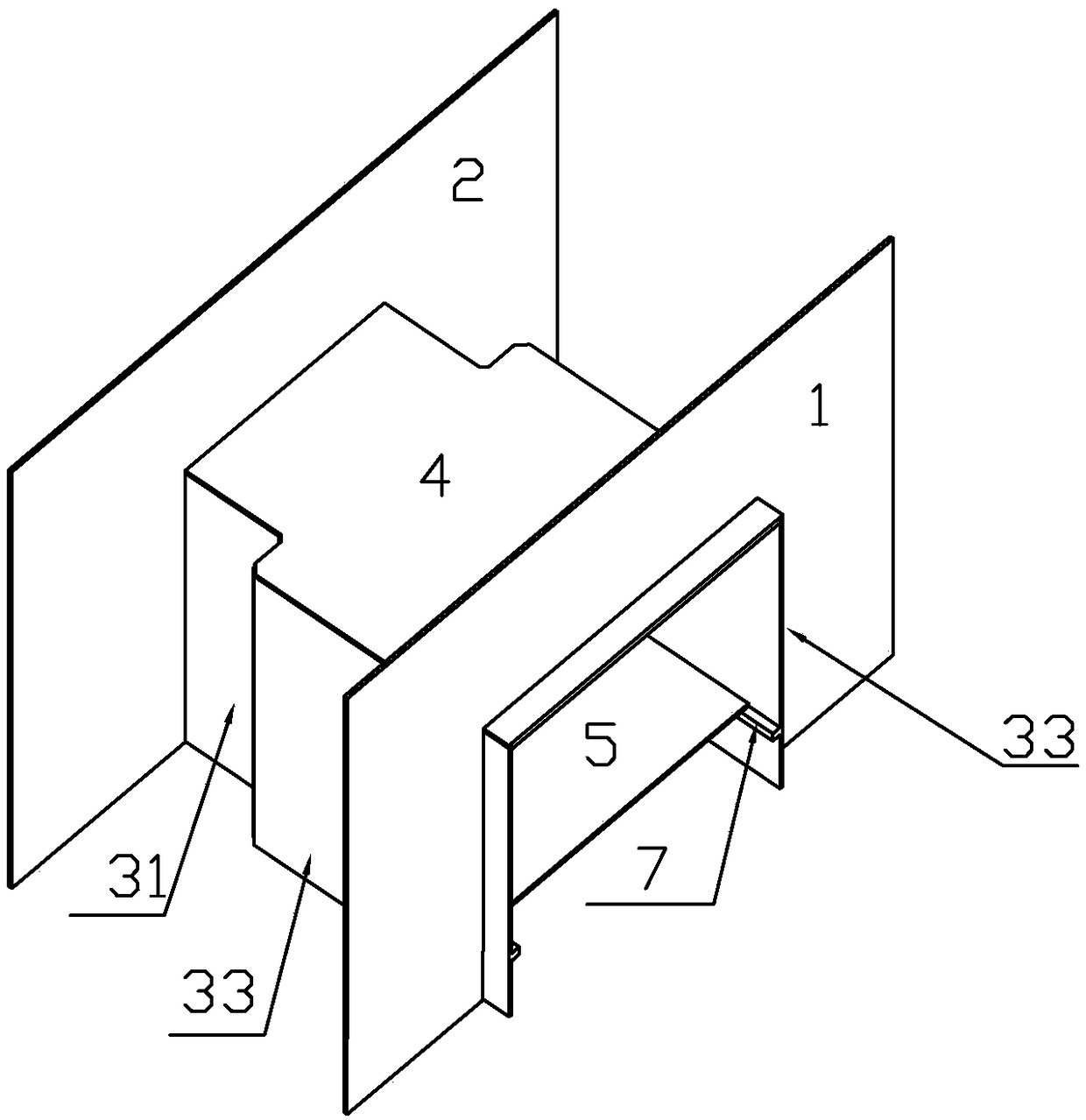

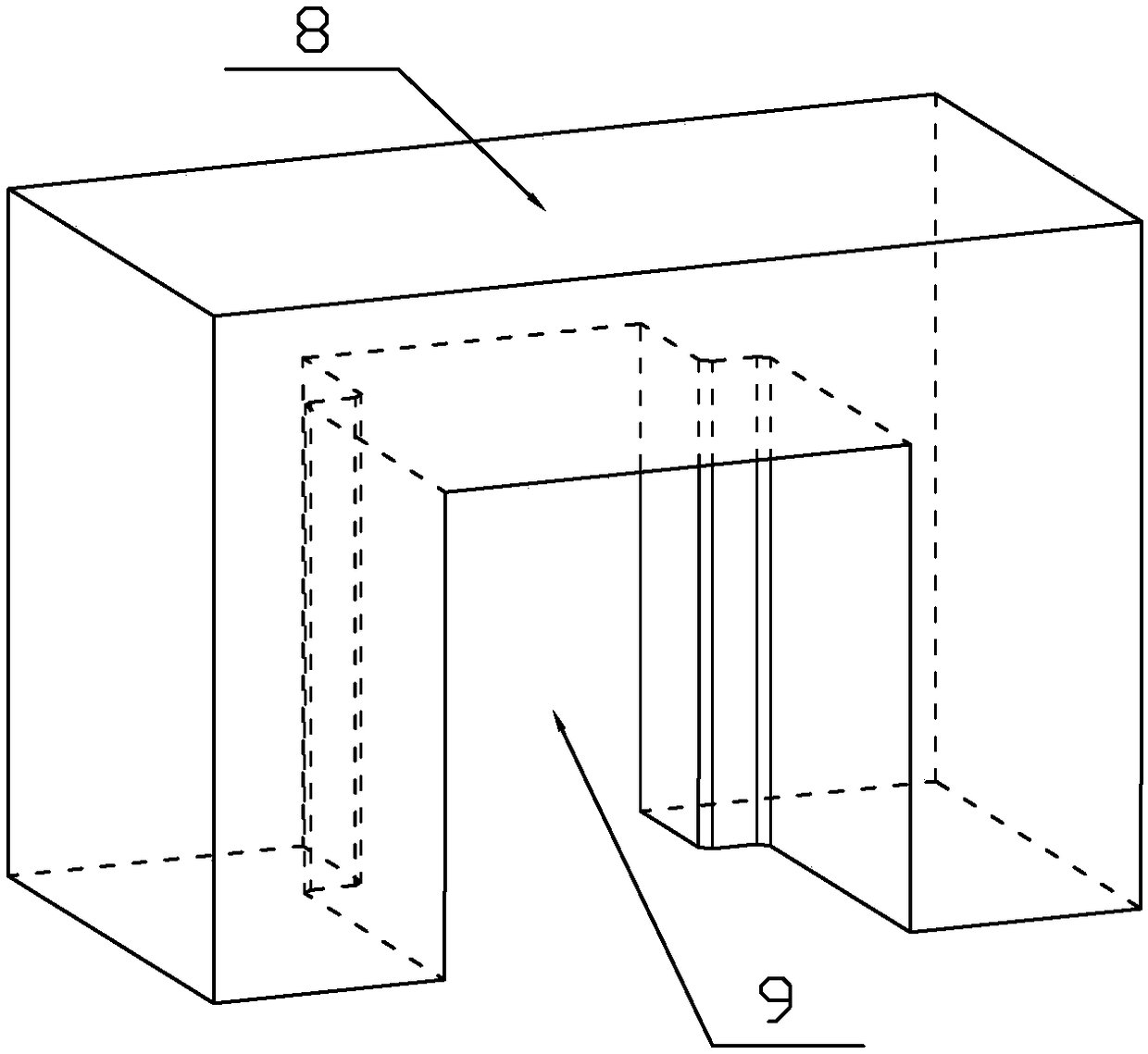

[0038] Implementation mode one: if Figure 1-2 As shown, the cantilever uses a shear wall reserved opening to form a combined formwork, including an inner formwork 1, an outer formwork 2, two vertical side panels 3, a roof 4 and a support plate 5, and the inner formwork 1 and the outer formwork 2 are provided with Opposed to the square notch 6, the upper surfaces of the front and rear ends of the top plate 4 are respectively attached to the upper edges of the two square notches 6, and the left and right sides of the top plate 4 are respectively pressed on the upper edges of the two vertical side plates 3, and the two vertical The side plates 3 abut against the side walls of the square notch 6 at the front and rear respectively, the support plate 5 is parallel to the top plate 4 , and its left and right ends respectively abut against the inner surfaces of the two vertical side plates 3 . The horizontal width of the square notch 6 of the inner template 1 is greater than the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com