Diesel engine pressurized air bypass device

A technology for supercharging air and diesel engine, which is applied in the device field of reducing the supercharging pressure of the scavenging air box of the diesel engine and the device field of optimizing the diesel engine load, can solve the problems of increasing the operating cost of the diesel engine, the electromagnetic valve is easily damaged, and the cost of the electromagnetic valve is high. Fewer parts, lower operating costs, and lower manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

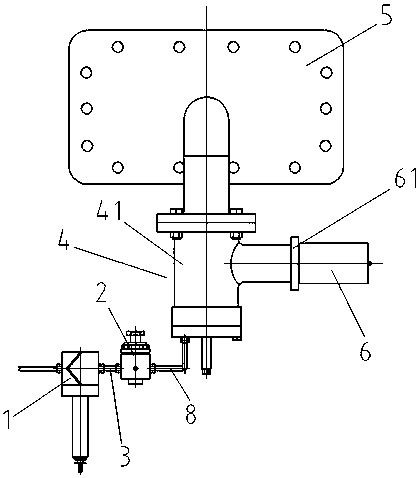

[0018] Such as figure 1 and figure 2 As shown, the present invention includes an air filter 1, a pressure reducing valve 2, a compressed air input pipe 3 and a bypass valve 4, the compressed air input pipe 3 is connected to the air filter 1 and the pressure reducing valve 2 in sequence, and the pressure reducing valve 2 can be used to set the desired pressure of compressed air entering the bypass valve. The upper end of the bypass valve 4 is connected with the cover plate 5 of the diesel engine scavenging air box.

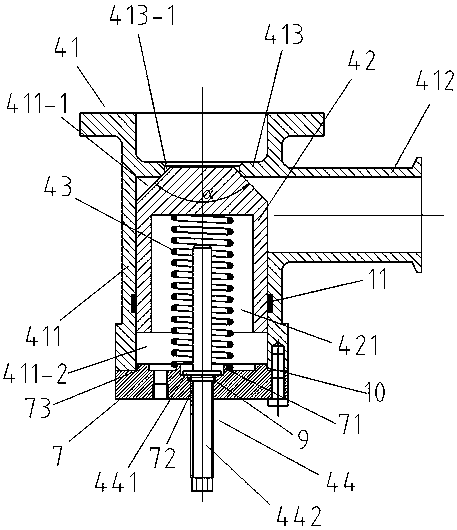

[0019] The bypass valve 4 includes a bypass valve body 41, a valve core 42, a spring 43 and a valve stem 44. The bypass valve body 41 is an inverted T-shaped cavity structure, including vertically connected longitudinal tubes 411 and bypass horizontal tubes 412. The upper end of the longitudinal tube 411 is provided with a transverse ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com