Exhaust gas system with thermoelectric generator

A technology of thermoelectric generators and exhaust devices, which is applied in the direction of exhaust devices, exhaust treatment, noise reduction devices, etc., and can solve problems such as material damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

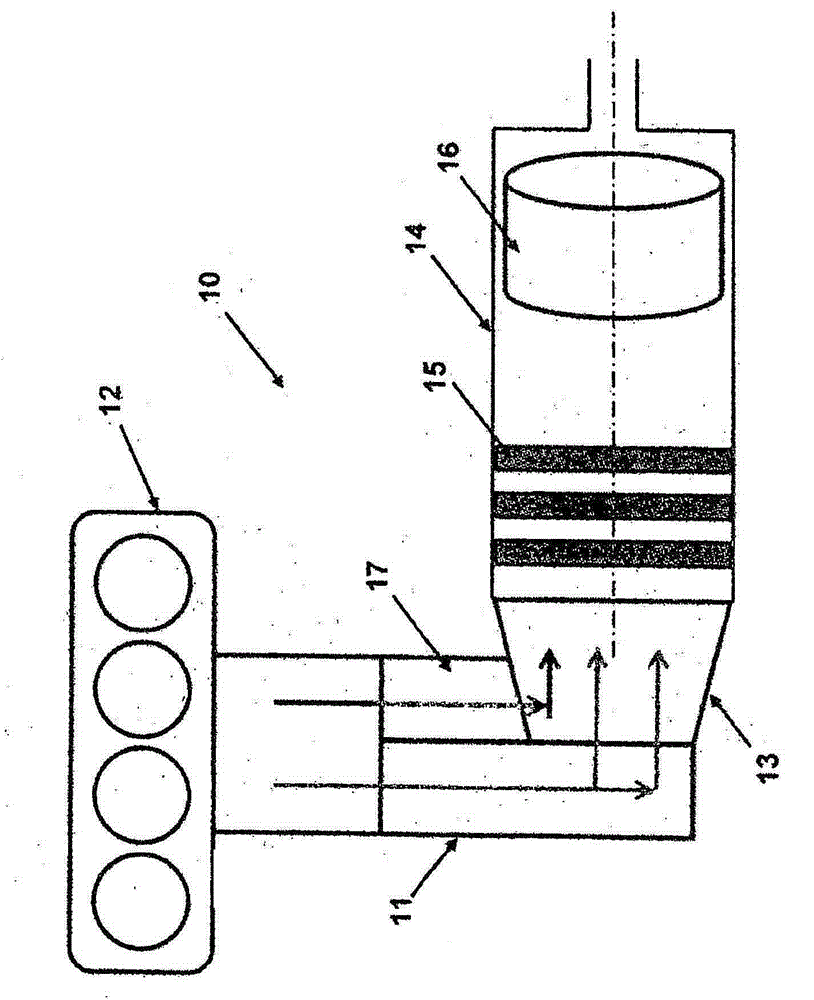

[0031] exist figure 1 An exhaust device 10 according to the prior art is shown in . The exhaust system 10 includes an exhaust pipe 11 with an elbow (manifold) 12 which can be connected, for example, to an internal combustion engine of a motor vehicle (not shown) for the purpose of discharging the exhaust gas. In addition, the exhaust gas pipe 11 comprises an exhaust gas turbocharger with a turbine 13 and a downstream flame pipe 14 with an integrated thermoelectric generator 15 and an exhaust gas catalytic converter arranged behind it in the flow direction. 16. The exhaust gas catalytic converter is designed as an axial catalytic converter, for example. Furthermore, the exhaust device 10 can be divided into a hot side (“Hot end”) and a cold side (“Cold End”), wherein the “Hot end” includes the following components: exhaust pipe 11 , elbow 12 , turbine 13 and bypass pipe 17. In this case, the "Cold End" includes the following components: the flame tube 14 and the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com