Kitchen fresh air system

A technology for fresh air system and kitchen, applied in ventilation system, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of inability to deliver fresh and clean fresh air to the kitchen, and inability to improve the combustion efficiency of stoves, and achieve the improvement effect, The effect of stove combustion suppression and kitchen environment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

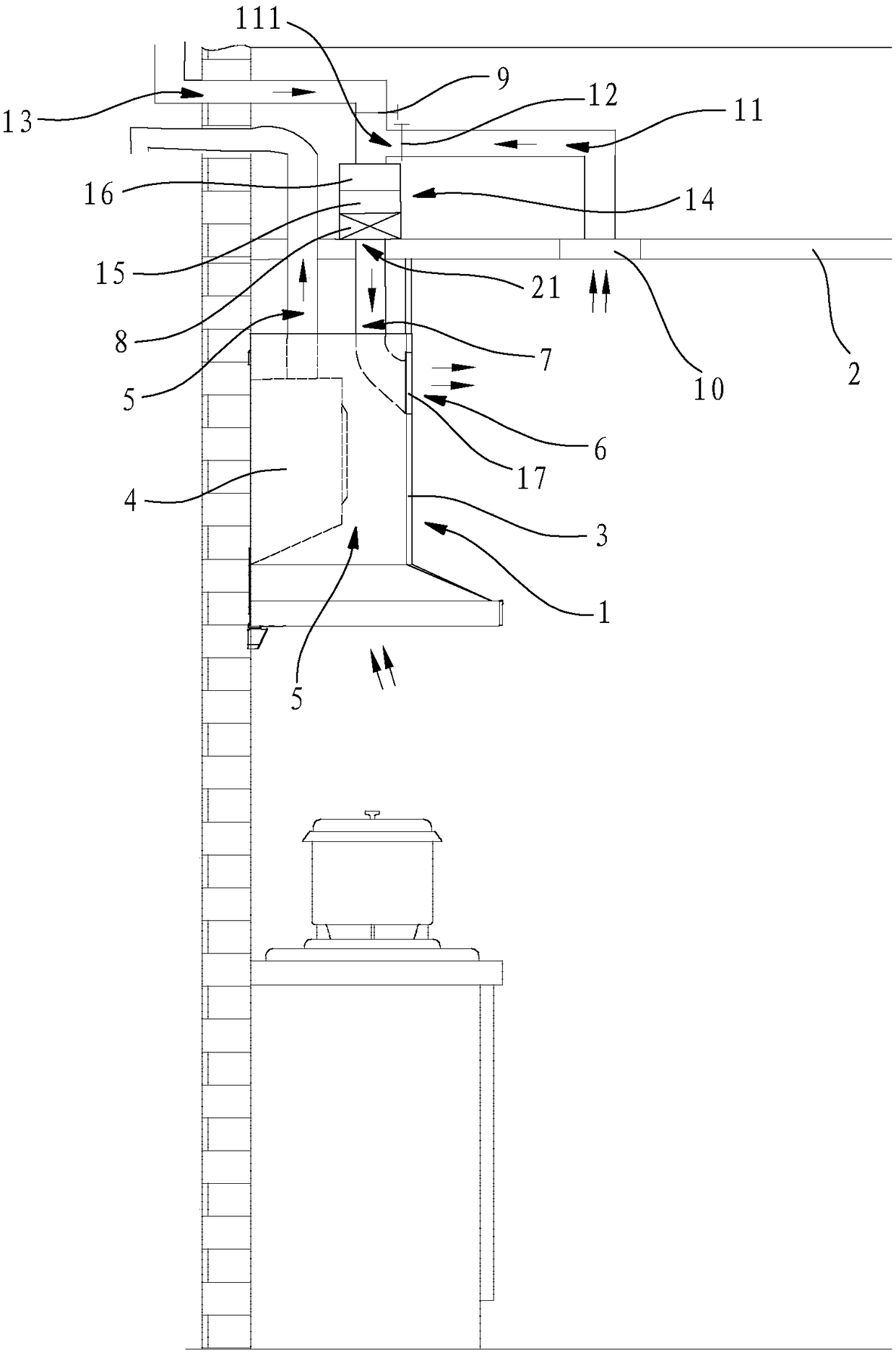

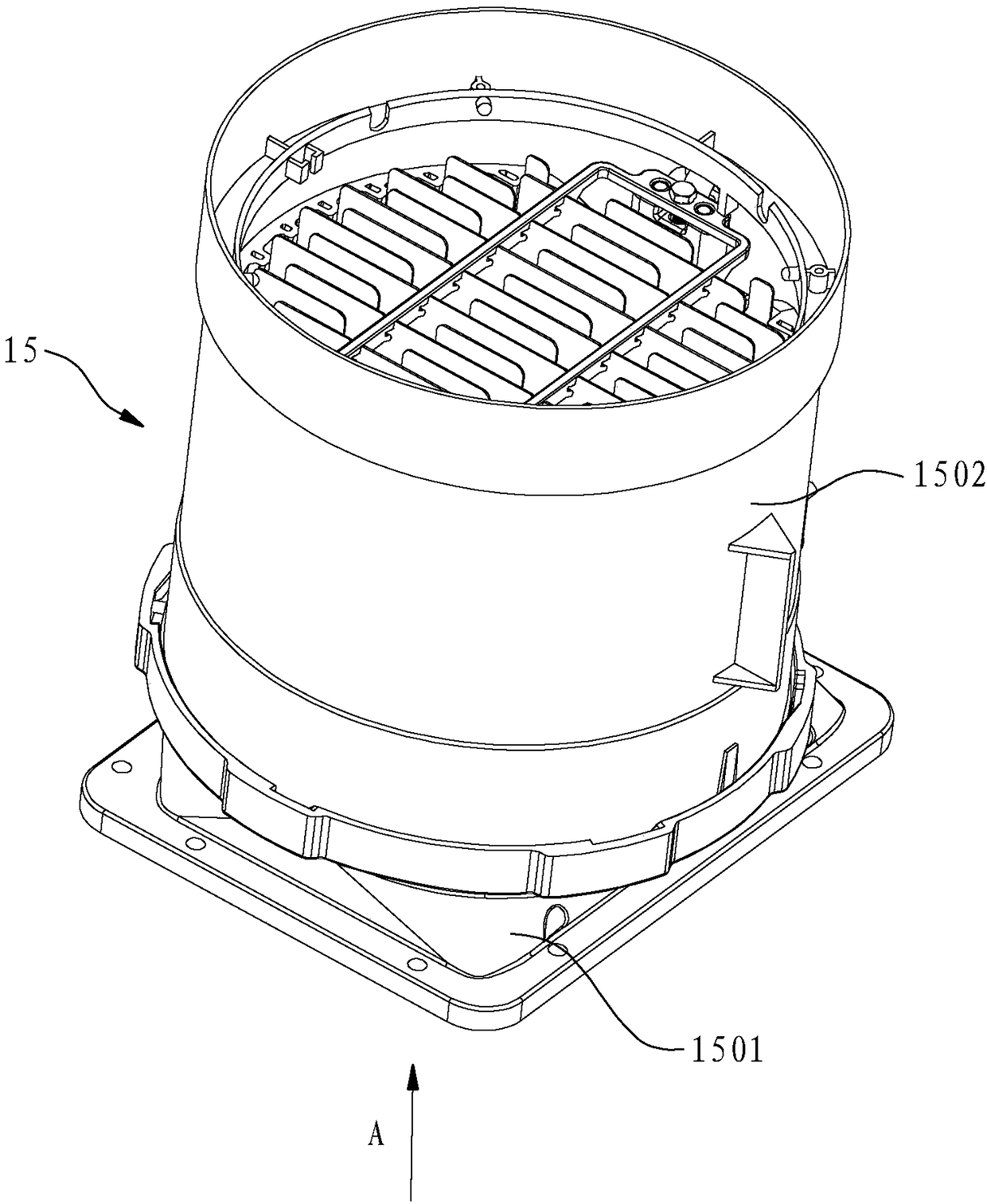

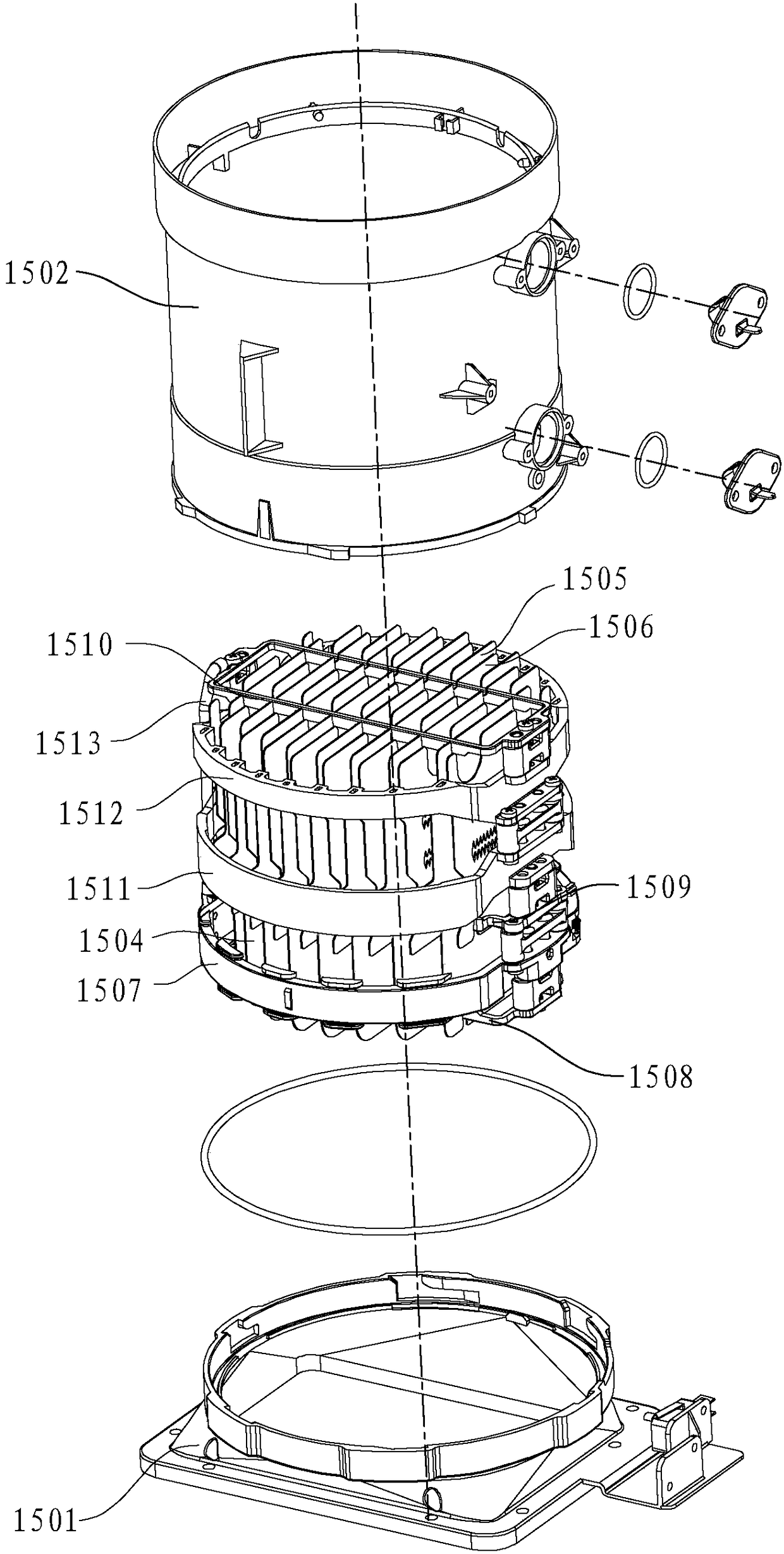

[0031] Such as figure 1 As shown, the kitchen fresh air system in this embodiment includes a range hood 1 , a range hood 5 and a ceiling 2 , and the range hood 1 includes a casing 3 and a range hood blower 4 inside the casing. The front of the casing 3 is provided with a fresh air outlet 6, and the casing 3 is provided with a fresh air inlet 21 and a fresh air outlet 6. The fresh air inlet 21 communicates with the outdoor, and the fresh air outlet 6 communicates with the room. 3. A first fresh air channel 7 connecting the fresh air inlet 21 and the fresh air outlet 6 is provided inside.

[0032]In this embodiment, the fresh air inlet 21 communicates with the outside through the second fresh air passage 13 , and the second fresh air passage 13 is located above the suspended ceiling 2 . A fresh air blower 8 , a fresh air purification device 14 and a first one-way valve 9 are installed in the second fresh air channel 13 . An air inlet 10 is provided on the suspended ceiling 2, ...

Embodiment 2

[0045] Such as Figure 6 As shown, the kitchen fresh air system in this embodiment is equipped with an oil fume purification device on the oil fume passage, and the oil fume purification device is a rear-end electrostatic purification device 20 arranged above the suspended ceiling 2 . The separation degree of grease is improved by setting the rear-end electrostatic purification device 20, thereby improving the cleanliness of exhausted oil fumes. The back-end electrostatic purification device 20 can adopt the structure of the electrostatic purification unit in the first embodiment, and the rest of the structure and working principle of this embodiment are the same as the fresh air system in the first embodiment, and will not be described here.

Embodiment 3

[0047] Such as Figure 7 As shown, the oil fume passage 5 of the kitchen fresh air system in this embodiment communicates with the second fresh air passage 13, a third check valve 18 is installed on the oil suction passage 5, and the oil fume outlet of the oil suction passage 5 It is located on the second fresh air channel 13 between the air inlet of the fresh air purification device 14 and the first one-way valve 9 . In addition, the oil fume purification device 14 is arranged on the oil fume passage between the air inlet of the range hood and the third check valve 18. In this embodiment, the oil fume purification device is integrated inside the casing 3 and located at the inlet of the range hood The front end electrostatic cleaning device 19 at the tuyere front end.

[0048] The working mode and principle of the fresh air system are as follows:

[0049] 1) When cooking, the range hood blower operates normally, the third one-way valve 18 is opened, the fresh air system is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com