Calibration Method for Multidimensional Polyline Segment Measurement

A polyline segment and calibration method technology is applied in the field of multi-dimensional polyline segment measurement and calibration method, which can solve the problems of difficulty of two-dimensional calibration of sample data, problems in the use of polyline segment calibration method, etc., so as to improve measurement accuracy and achieve good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

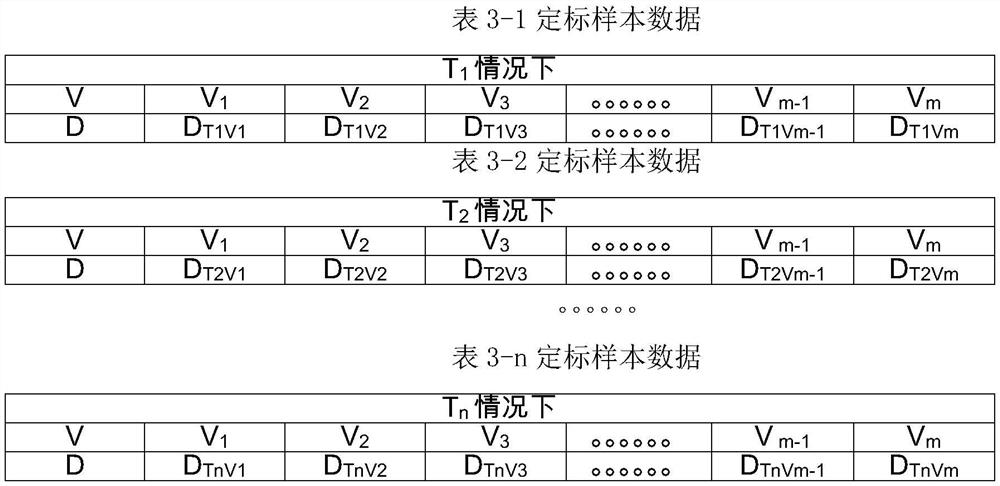

[0051] The measured audio voltage is denoted as v, the direct measurement parameter is ADC sampling data, denoted as d, and the temperature is a factor affecting the measurement, denoted as t.

[0052] The first step is to determine the measurand, the directly measured parameters and all factors affecting the measurement. In this example, the audio voltage v is measured, the direct measurement parameter is ADC sampling data d, and the factor affecting the measurement is temperature t.

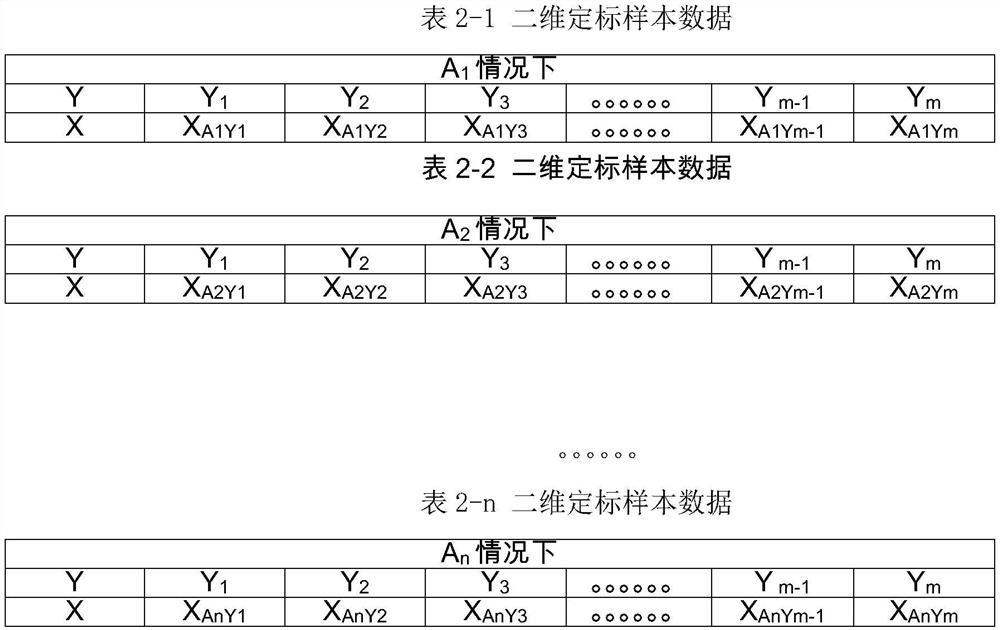

[0053] The second step is to determine the number of measurement points for each influencing factor and the number of direct measurement parameters, and measure the value of the direct measurement parameter through the standard measured value, that is, the calibration sample data. In this example, the number of measurement points affecting the measurement factor t is n, that is, T 1 , T 2 ...T n , the number of measurement points for direct measurement of parameter d is m, and since there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com