Automatic capillary water absorption measuring device and method for building porous material

A porous material and capillary water absorption technology, applied in the field of construction technology and science, can solve problems such as waste of manpower, small weighing results, and high professional requirements for operation, and achieve the effects of eliminating waste of manpower, accurate results, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

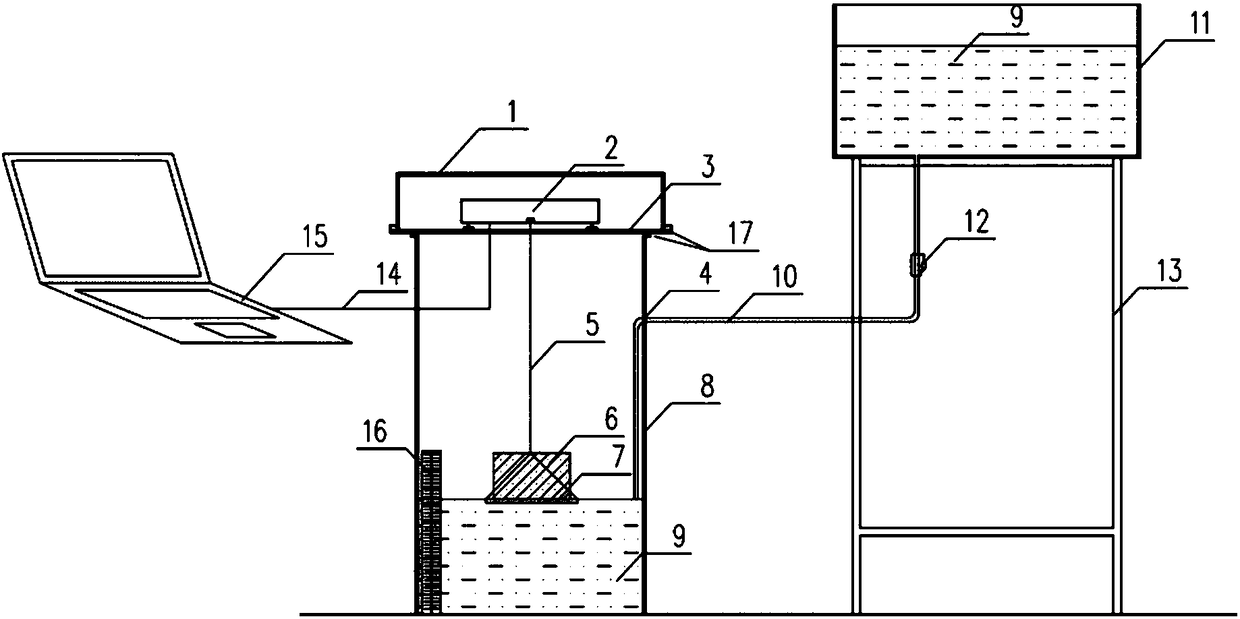

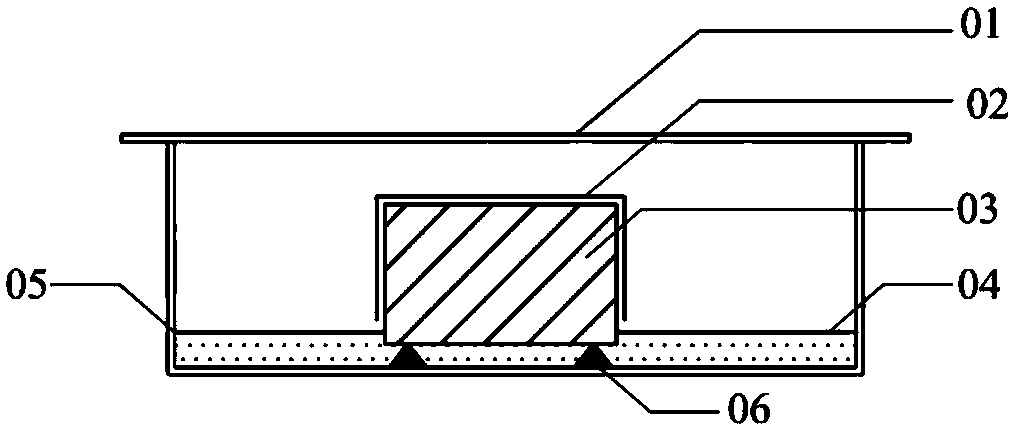

[0037] An automatic measuring device for capillary water absorption of building porous materials, comprising a windproof glass cover 1, an electronic balance 2, a glass platform 3, a metal hanger 5, a mesh metal gasket 7, a glass water tank 8, an infusion tube 10, a high-level water tank 11, Electronic computer 15, water level sticker 16, limit soft strip 17; The test piece 6 is placed on the mesh metal gasket 7, and the mesh metal gasket 7 is suspended directly below the electronic balance 2 through the metal hanger 5, and the electronic balance 2 is set on the glass platform 3, and the glass platform 3 is connected with the glass water tank 8 through the limit soft strip 17; the windshield 1 is covered above the electronic balance 2 and fixed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com