Method of predicating internal corrosion degrees of on-service oil and gas pipelines

A technology for oil and gas transportation and internal corrosion, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., and can solve the problems of blind internal inspection work and perforation of long-distance oil and gas pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

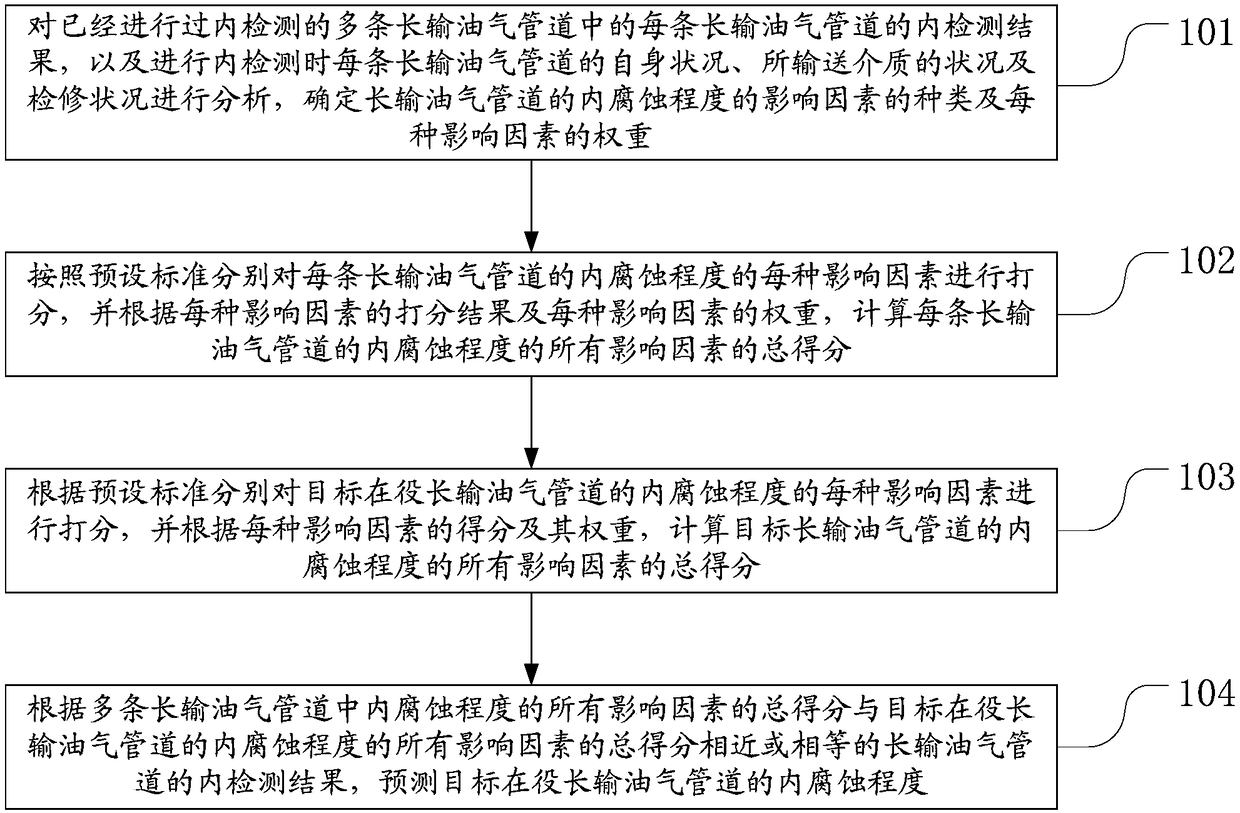

[0054] Such as figure 1 As shown, the embodiment of the present invention provides a method for predicting the internal corrosion degree of long-term oil and gas pipelines in service, the method comprising:

[0055] In step 101, the internal inspection results of each long oil and gas pipeline among the multiple long oil and gas pipelines that have been internally inspected, as well as the condition of each long oil and gas pipeline when the internal inspection is performed, and the transport medium The status and maintenance status are analyzed to determine the types of factors affecting the degree of internal corrosion of long-distance oil and gas pipelines and the weight of each factor.

[0056] In the embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com