Design method and system for industrial robot based on four-axis iterative learning control

An iterative learning control, industrial robot technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as ILC can no longer be effectively applied, control information cannot be effectively used, and three-dimensional parts cannot be processed. Achieve the effect of increasing diversity, speeding up learning, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

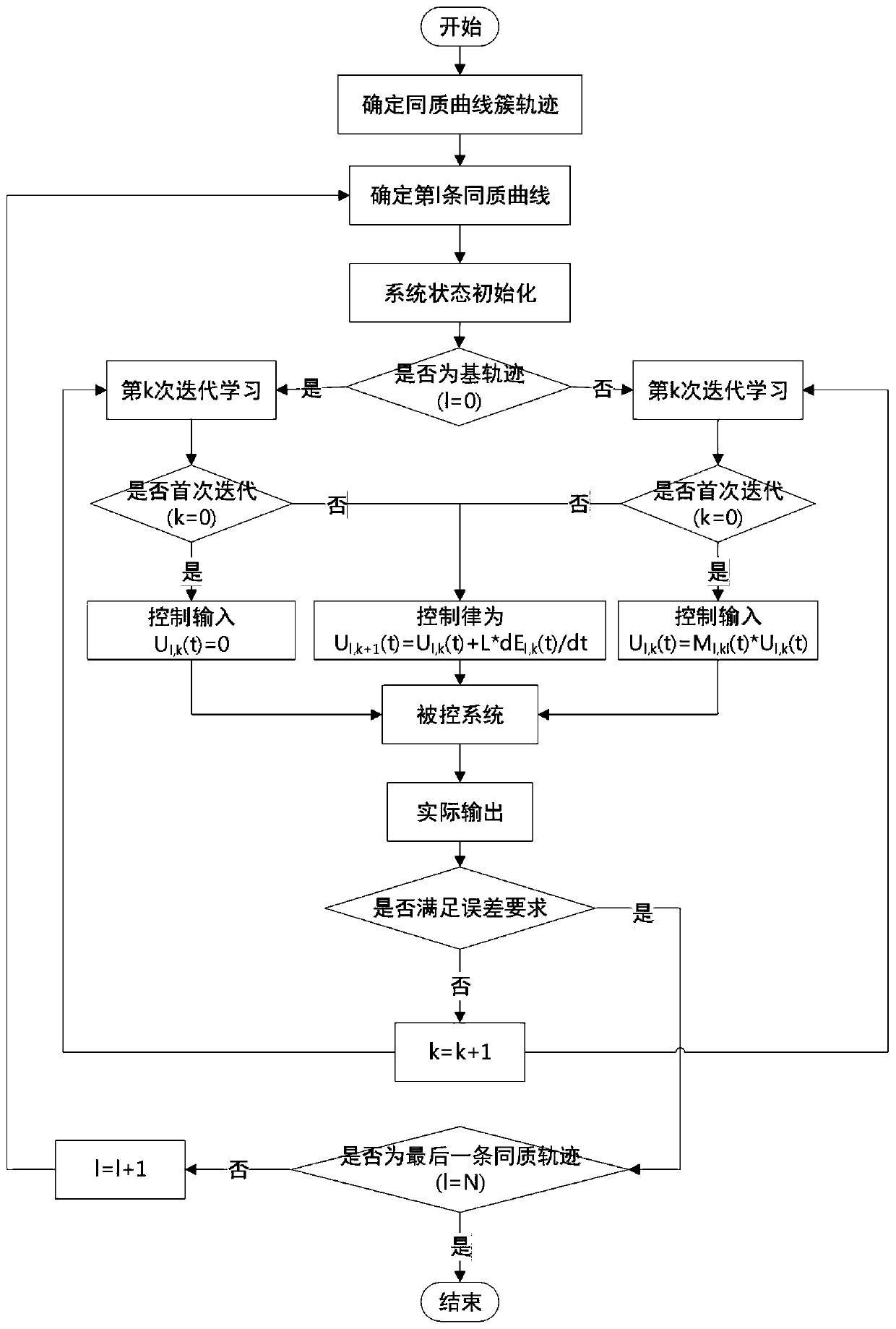

[0028] The industrial robot design method of four-axis iterative learning control provided by the invention (see figure 1 ), including:

[0029] Step 1: Establish the corresponding homogeneous curve cluster trajectory according to the three-dimensional parts that the industrial robot needs to process.

[0030] Among them, the homogeneous curve cluster trajectory is a kind of trajectory group with similar shape and different amplitude characteristics. The traditional iterative learning control has time axis, amplitude axis and iteration axis. However, compared with the traditional iterative learning control, the present invention includes the existing In addition to the three axes, this kind of trajectory group is also used as a unique fourth axis-the trajectory axis.

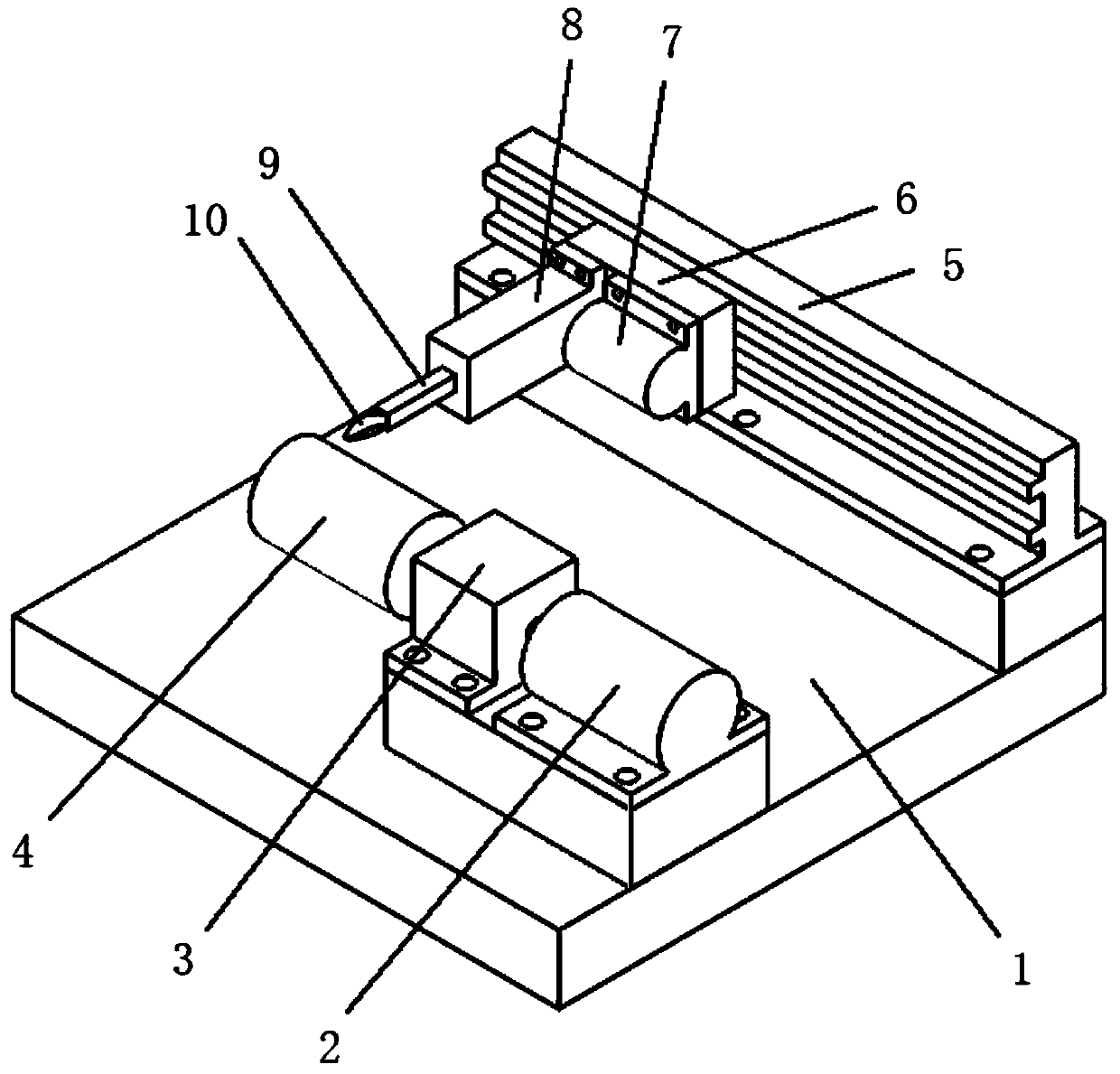

[0031] Step 2: Select the motion mechanism of the industrial robot as the analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com