Spiral linear motor

A linear motor and screw technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of electromagnetic thrust, efficiency, low power factor, unbalanced winding current, large magnetizing current, etc. Enhanced electromagnetic thrust, easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

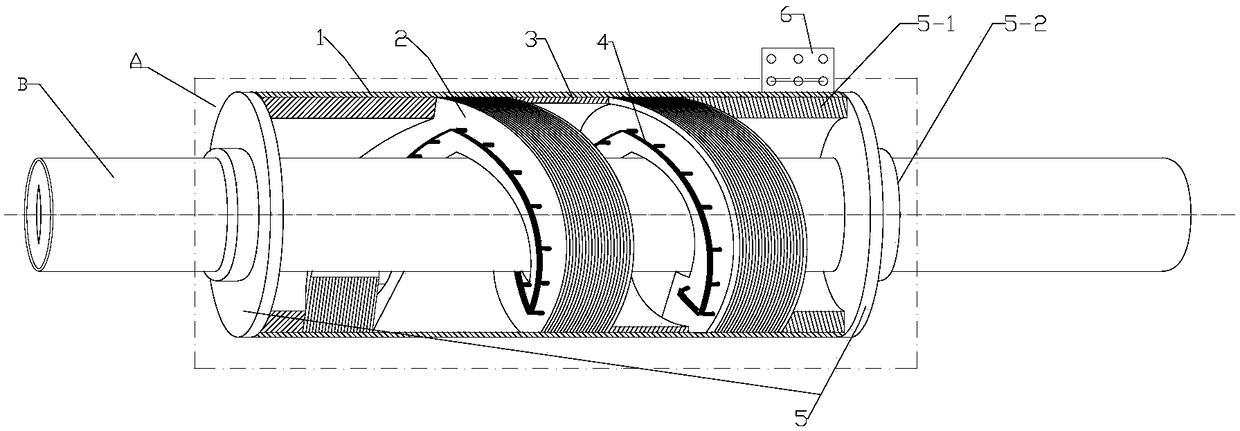

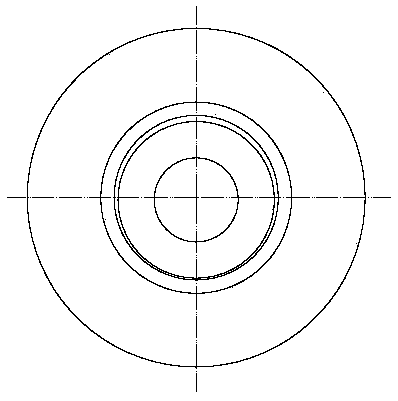

[0020] Such as figure 1 , 2 Shown: a helical linear motor, including: a stator A, a mover B set with the stator A; the stator A is composed of a shell 1, a spiral iron core 2 and a spiral spacer 3 set in the shell 1, The windings 4 distributed in several notches of the spiral core 2 are composed of two end caps 5 connected to the two ends of the housing 1; the characteristic is that the spiral core 2 is composed of inner circles or outer circles of several annular silicon steel sheets. Punch evenly distributed notches, and break a gap at the same position of several annular silicon steel sheets; pull several annular silicon steel sheets axially from the gap to form spiral silicon steel sheets with equal pitch, and several spiral silicon steel sheets After the two sides are coated with an insulating layer, they are stacked together in the axial direction, and the notches of several spiral silicon steel sheets are aligned, and the axes of the notches must be perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com