Drawing space purifying device

A technology for purifying devices and spaces, applied in chemical instruments and methods, removing smoke and dust, cleaning methods and utensils, etc., can solve problems such as reduced air quality in workshops, uneven film thickness, rust on extrusion die lips, etc., and achieves a degree of automation. High, workshop environment improvement, the effect of reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

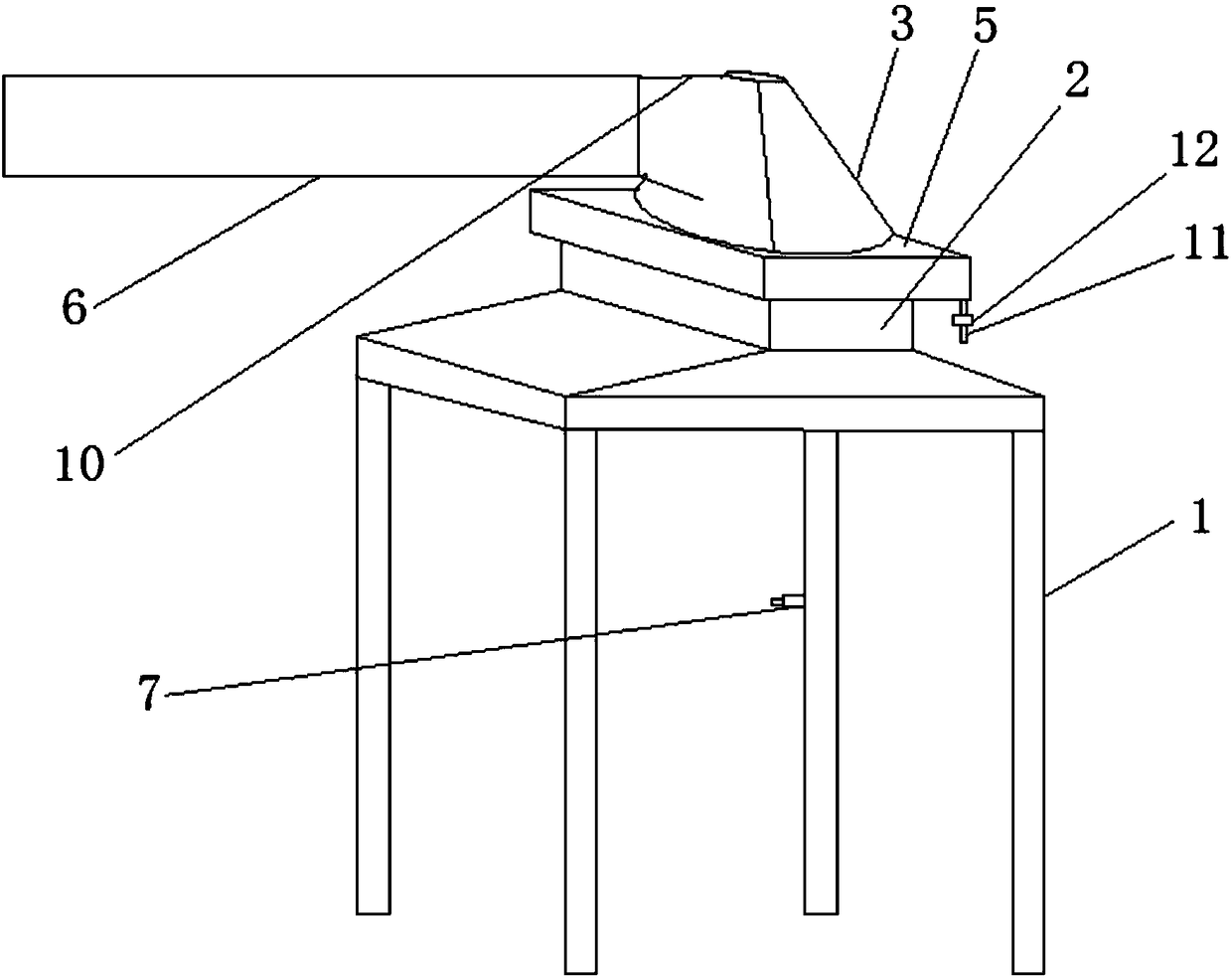

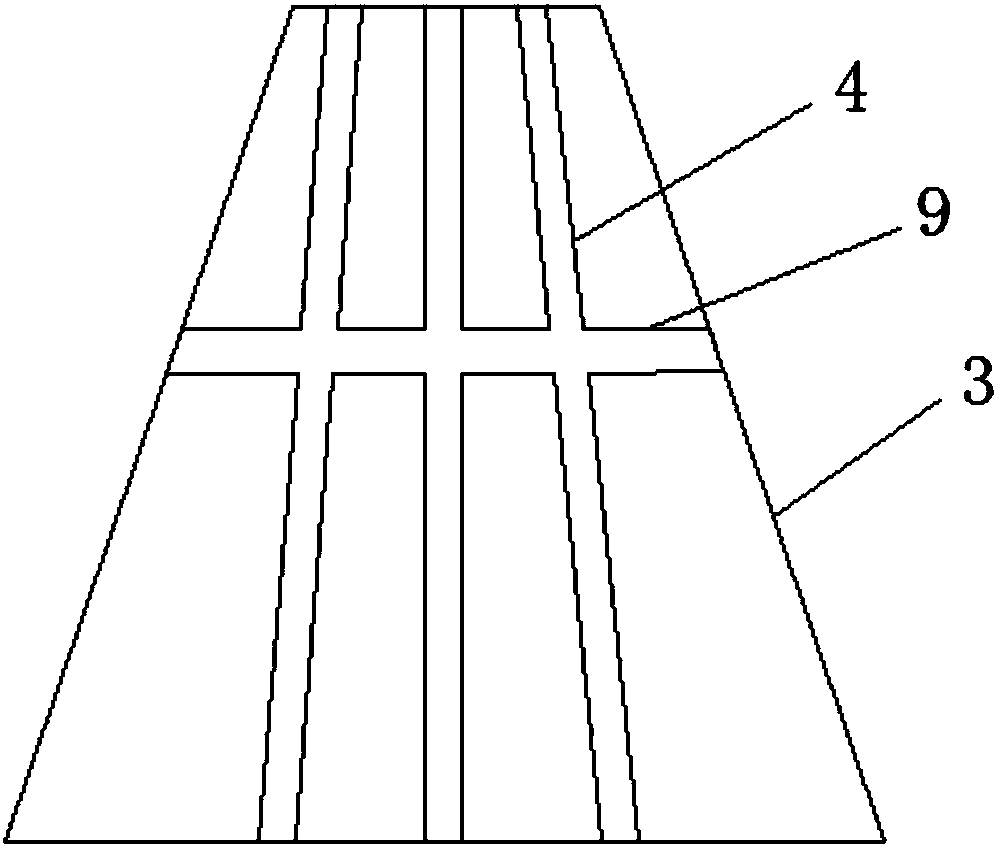

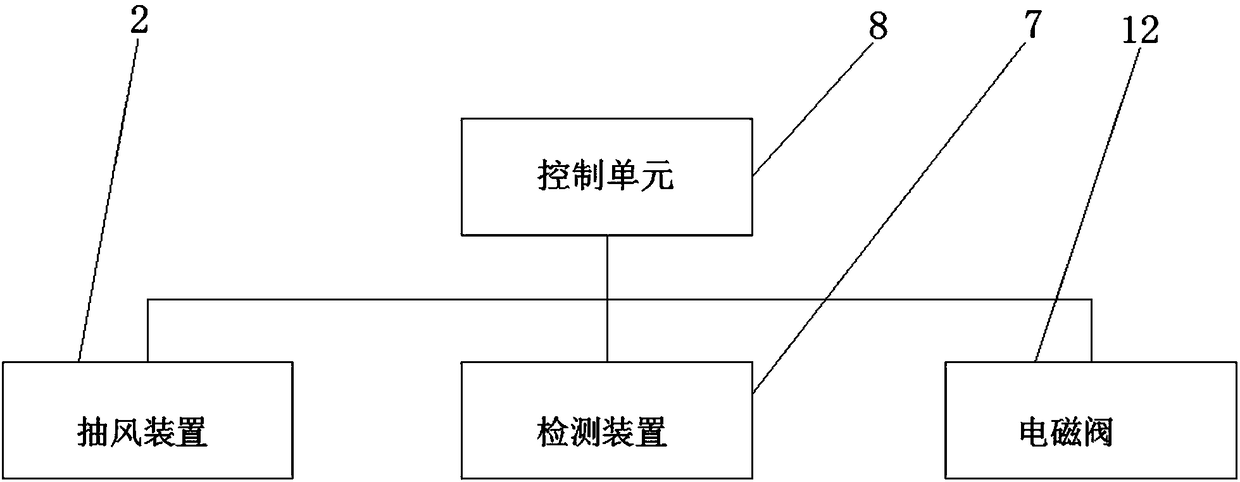

[0018] The specific embodiment of the present invention is like this: as Figure 1-3 As shown, a drawing space purification device includes a support frame 1 erected on a water cooling device. The top of the support frame 1 is provided with an exhaust device 2 that draws water vapor upward. The outlet of the exhaust device 2 is connected to a fairing 3, and the fairing 3 is provided with an arc surface structure, the fairing 3 can turn the water vapor into a liquid state, and facilitate the export of air flow, the inner wall of the fairing 3 is provided with a diversion groove 4 extending from top to bottom, and the bottom of the fairing 3 is provided with The water collection and drainage structure 5, the water flows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com