Door plank compressing mechanism and pipe expander with same

A technology of pressing mechanism and door panel, which is applied in the direction of manufacturing tools, heat exchange equipment, metal processing equipment, etc., can solve the problems of low efficiency, achieve the effect of ensuring the positioning effect and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

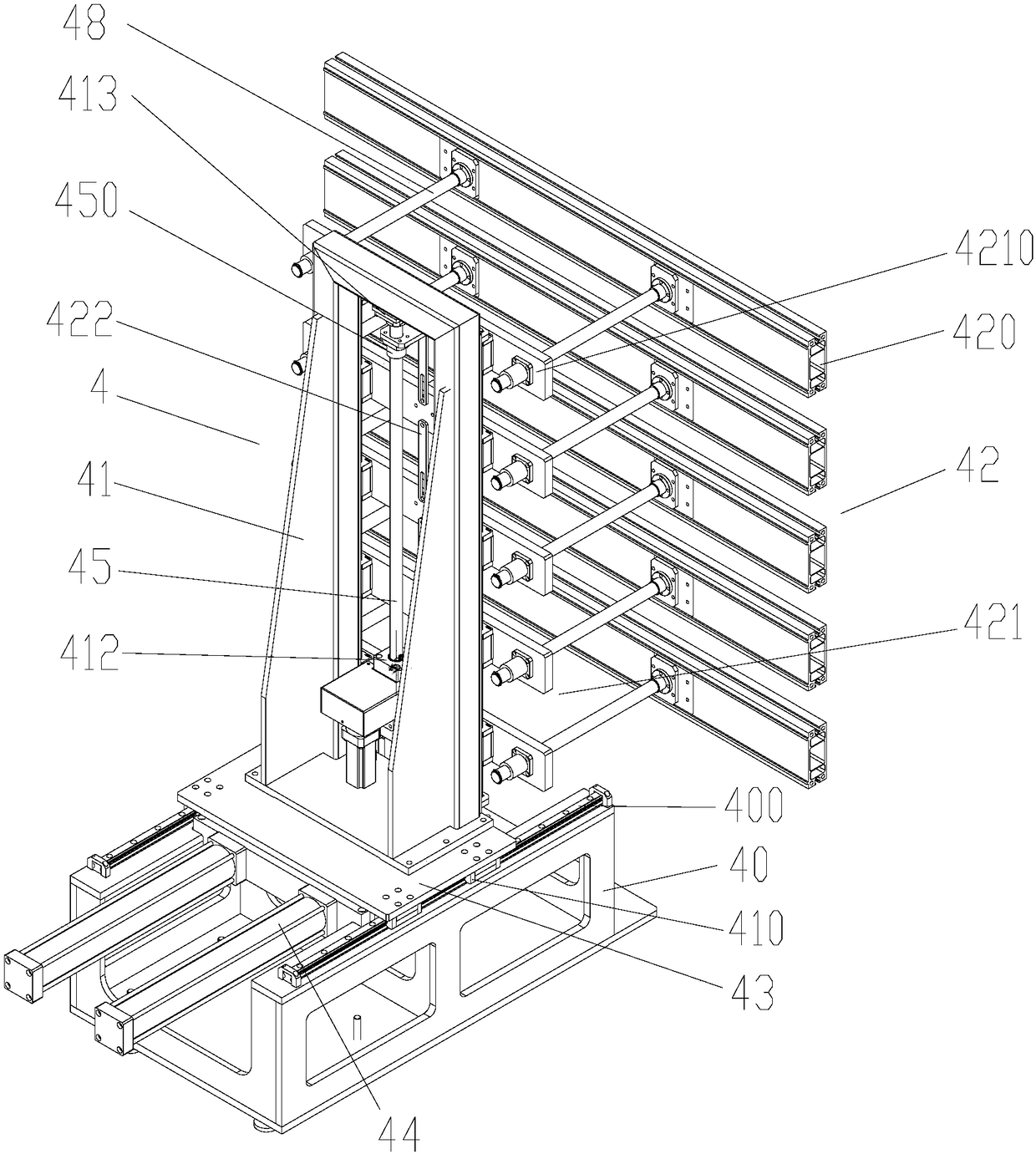

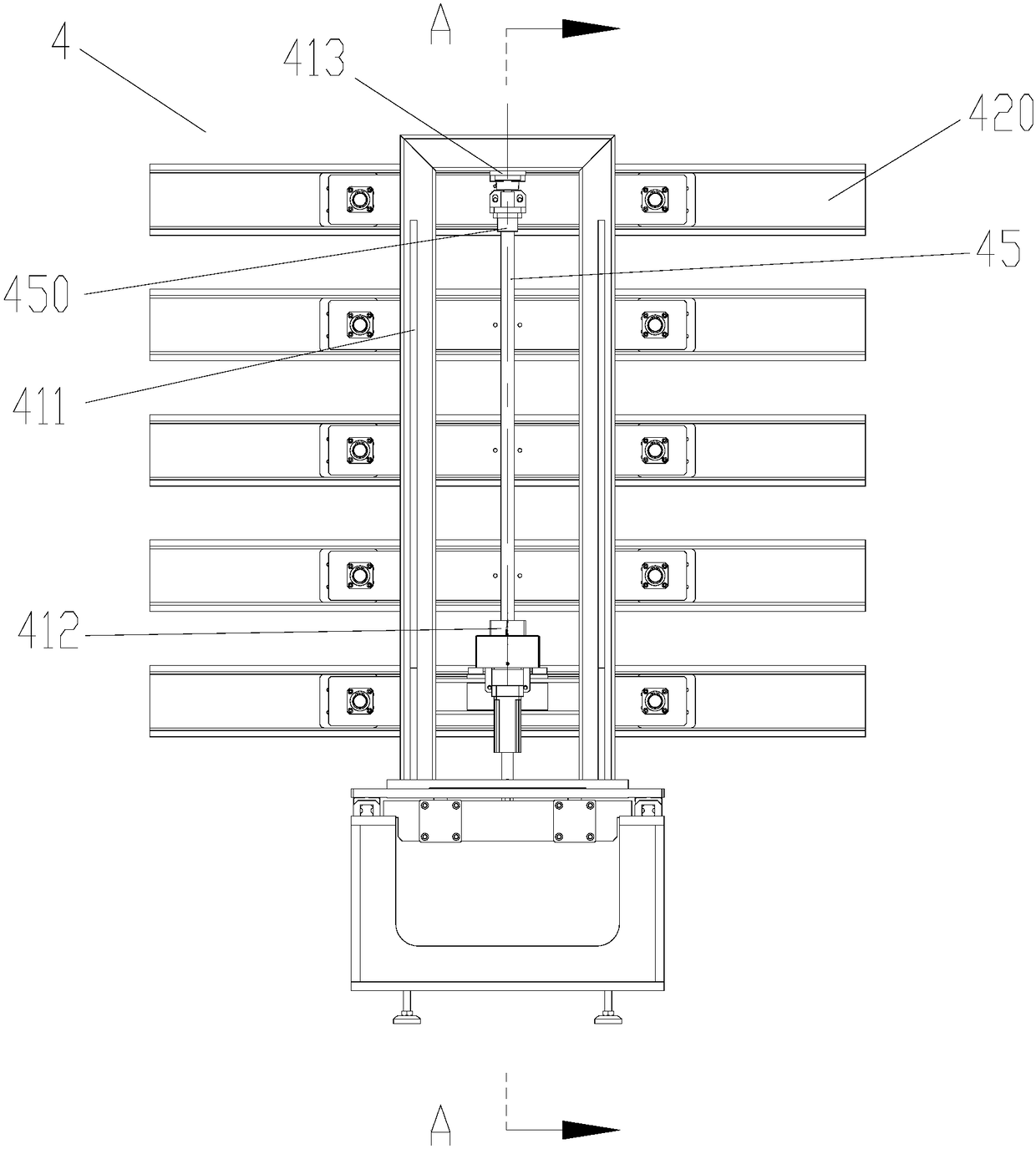

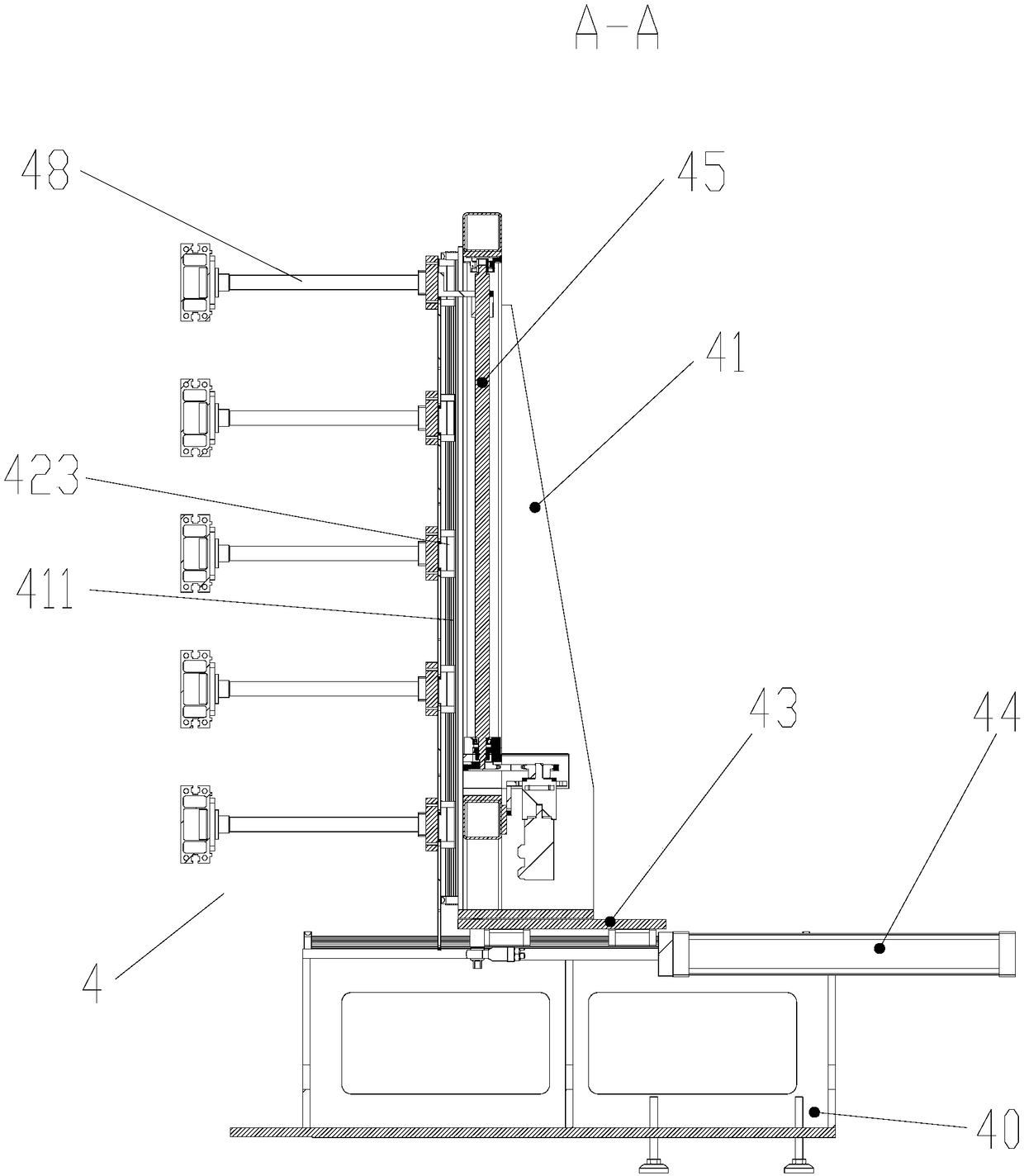

[0026] The present invention provides a door panel pressing mechanism, please refer to Figure 1 to Figure 4 , the door panel pressing mechanism includes: a fixed base 40; a door panel mounting bracket 41, an outer door panel assembly 42 for pressing the heat exchanger is installed on the door panel mounting bracket 41, and the door panel mounting bracket 41 is movably installed on the fixed base 40, to Drive the outer door panel assembly 42 to be pressed against the heat exchanger on the workbench.

[0027] The door panel pressing mechanism of the present invention includes a fixed base 40 and a door panel mounting bracket 41, wherein the door panel mounting bracket 41 is installed with an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com