Rail top derusting device for railway track maintenance

A railway track and rail technology, which is applied in the field of rail top rust removal devices for railway track maintenance, can solve the problems of reducing the tightness of positioning and fixing, wear of contact points, and failure of fastening components, so as to improve work continuity and reduce The effect of labor input and improvement of derusting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

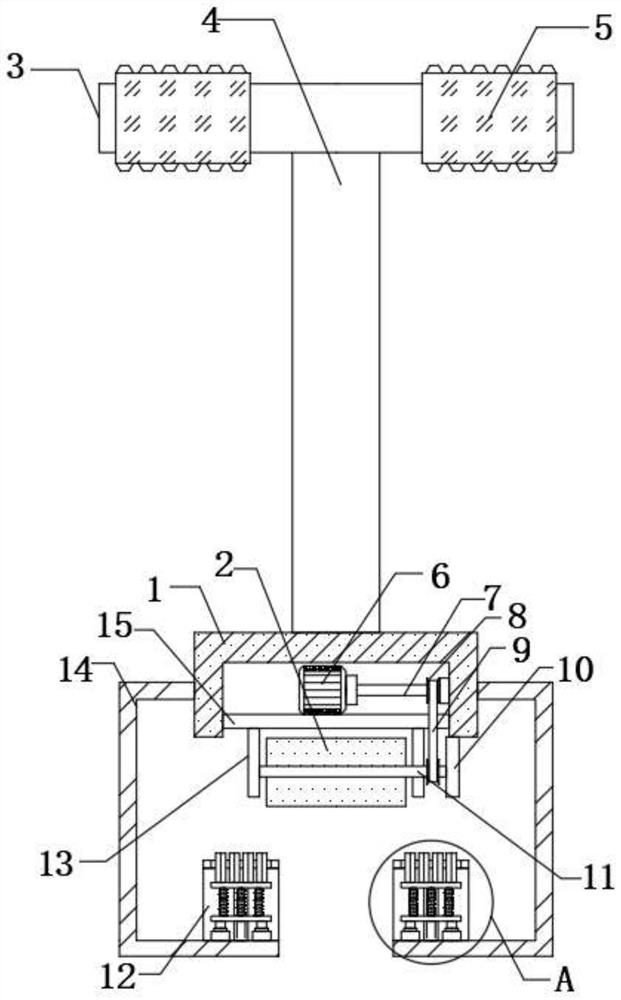

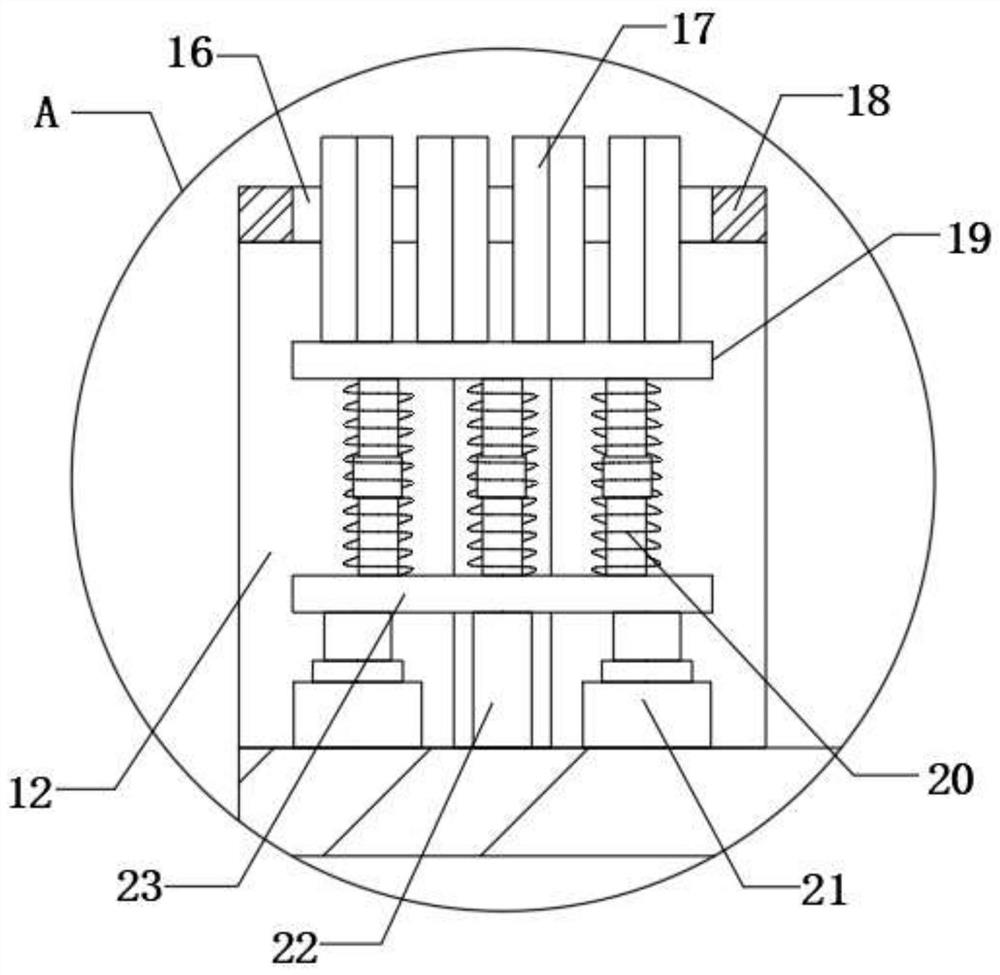

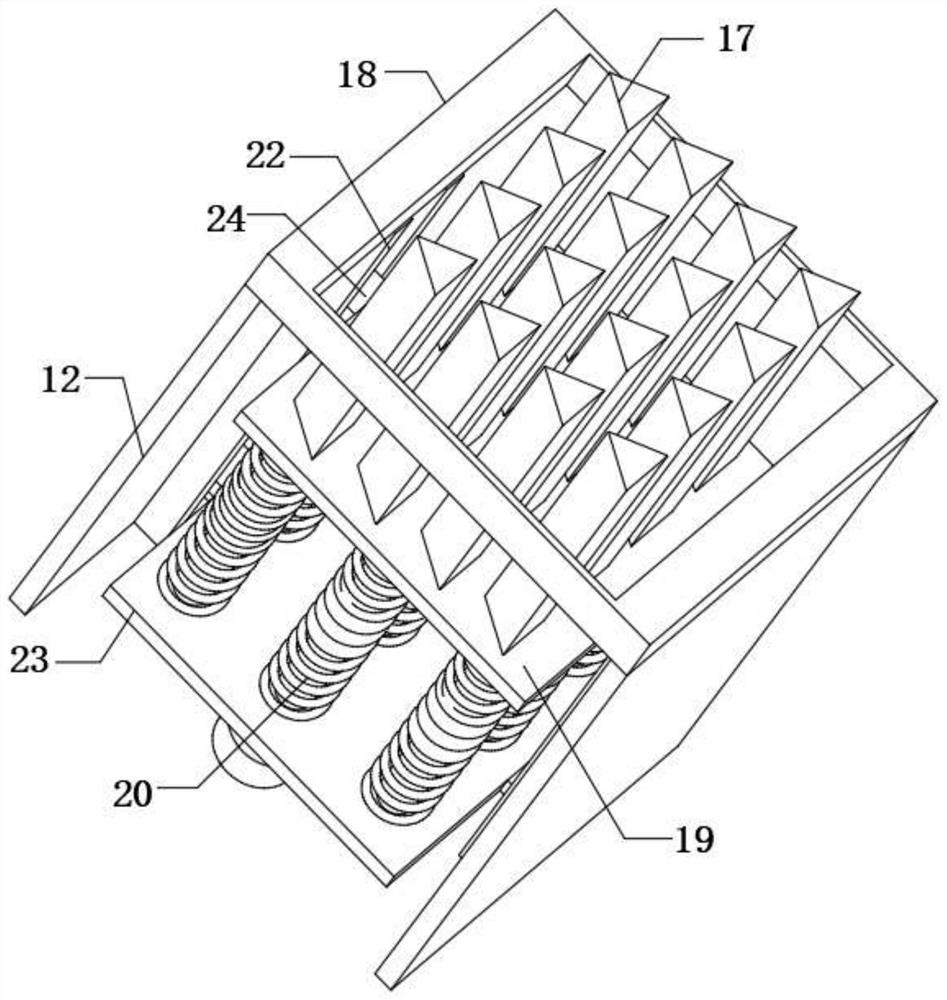

[0028] refer to Figure 1-3 , a rail top derusting device for railway track maintenance, comprising a mounting frame 1, the outer walls on both sides of the mounting frame 1 are fixedly connected with connecting frames 14, and the bottom inner walls of the two connecting frames 14 are fixedly connected with two fixing plates 12. The top outer walls of the two fixed plates 12 are fixedly connected with the same fixed frame 18, and the top outer walls of the fixed frame 18 are provided with ejection holes 16, and the opposite sides of the two fixed plates 12 on the bottom inner wall of each connecting frame 14 The outer walls are fixedly connected to the limiting groove 22, and the inner walls of the two limiting grooves 22 are slidably connected with two sliders 24, and the outer walls on the opposite side of the two sliders 24 on different limiting grooves 22 above are fixedly connected. There is the same upper adjustment plate 19, and the opposite side outer walls of the two ...

Embodiment 2

[0036] refer to Figure 1-5 , a rail top derusting device for railway track maintenance, comprising a mounting frame 1, the outer walls on both sides of the mounting frame 1 are fixedly connected with connecting frames 14, and the bottom inner walls of the two connecting frames 14 are fixedly connected with two fixing plates 12. The top outer walls of the two fixed plates 12 are fixedly connected with the same fixed frame 18, and the top outer walls of the fixed frame 18 are provided with ejection holes 16, and the opposite sides of the two fixed plates 12 on the bottom inner wall of each connecting frame 14 The outer walls are fixedly connected to the limiting groove 22, and the inner walls of the two limiting grooves 22 are slidably connected with two sliders 24, and the outer walls on the opposite side of the two sliders 24 on different limiting grooves 22 above are fixedly connected. There is the same upper adjustment plate 19, and the opposite side outer walls of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com