Forming method of PVB film for HUD and PVB film prepared through same

A molding method and imaging technology, applied in the field of glass, can solve problems such as hidden dangers of safe driving, ghosting in HUD imaging, and changes in imaging clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

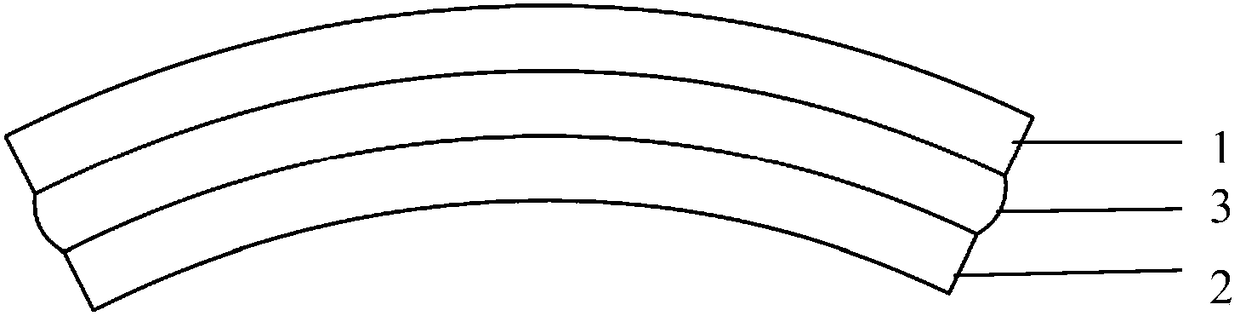

[0040] figure 1 Be the sectional view of common windshield in the prior art, refer to figure 1 It can be seen that a common windshield includes an outer glass 1 , an inner glass 2 and a common PVB film 3 with uniform thickness. The ordinary PVB film 3 has good cohesiveness, toughness and elasticity. When the windshield is violently impacted by an external force, the ordinary PVB film 3 will absorb a large amount of energy, and glass fragments will firmly adhere to the ordinary PVB film. Glass shards will not fly, thereby minimizing possible injuries. But the common PVB film 3 in the prior art is not suitable for HUD imaging, and reason is: common windshield is generally the form of laminated glass, and common windshield has the inclination angle, and under the situation of uniform PVB film thickness, the whole Ordinary windshields are generally uniform in thickness, so two reflected images that are staggered from each other will be formed during HUD imaging, so that two over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com