Friction braking device

A friction brake and brake cylinder technology, applied in the field of rail vehicle braking system, can solve the problems of difficult control, occupying vehicle space, complex structure, etc., and achieve the effects of reducing weight, improving service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The friction braking device of the present invention can be applied to maglev trains or light rail trains or trains. This embodiment takes the application of the friction braking device to maglev trains as an example.

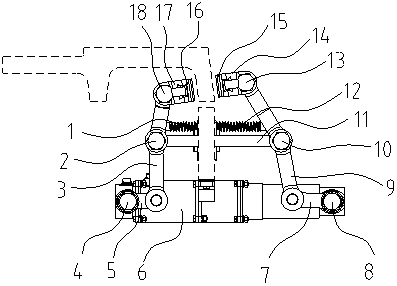

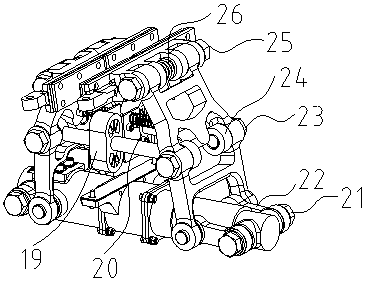

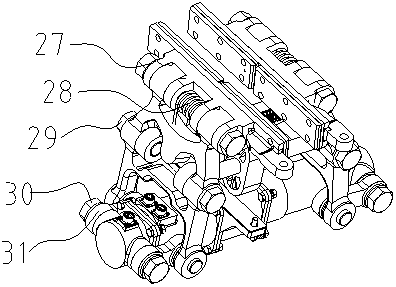

[0029] The friction braking device for maglev vehicles includes: return spring 1, bolt 2, lever 3, bolt 4, hinge lever 5, brake cylinder 6, hinge lever 7, bolt 8, lever 9, bolt 10, floating lever 11, return spring 12. Bolt 13, brake pad holder 14, brake pad 15, brake pad 16, brake pad holder 17, bolt 18, flexible block 19, flexible block 20, bolt 21, hinge rod 22, bolt 23, floating rod 24, nut 25 , Torsion spring 26, nut 27, torsion spring 28, bolt 29, bolt 30 and hinge lever 31 etc.

[0030] Among them, the hinge rod, lever, brake disc support and brake disc form the friction brake connector, and the floating rod, return spring and flexible block form the floating connector.

[0031] The brake cylinder is installed on the floating plate of the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com