Ventilation transport box equipment assembly

A technology for transportation boxes and equipment, which is applied in the direction of transportation and packaging, special packaging objects, bottle/can parts, etc., which can solve the problems of shortened shelf life, easy bumps, and perishability, etc., and achieve good shock absorption effect and shock absorption Good effect, good breathability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

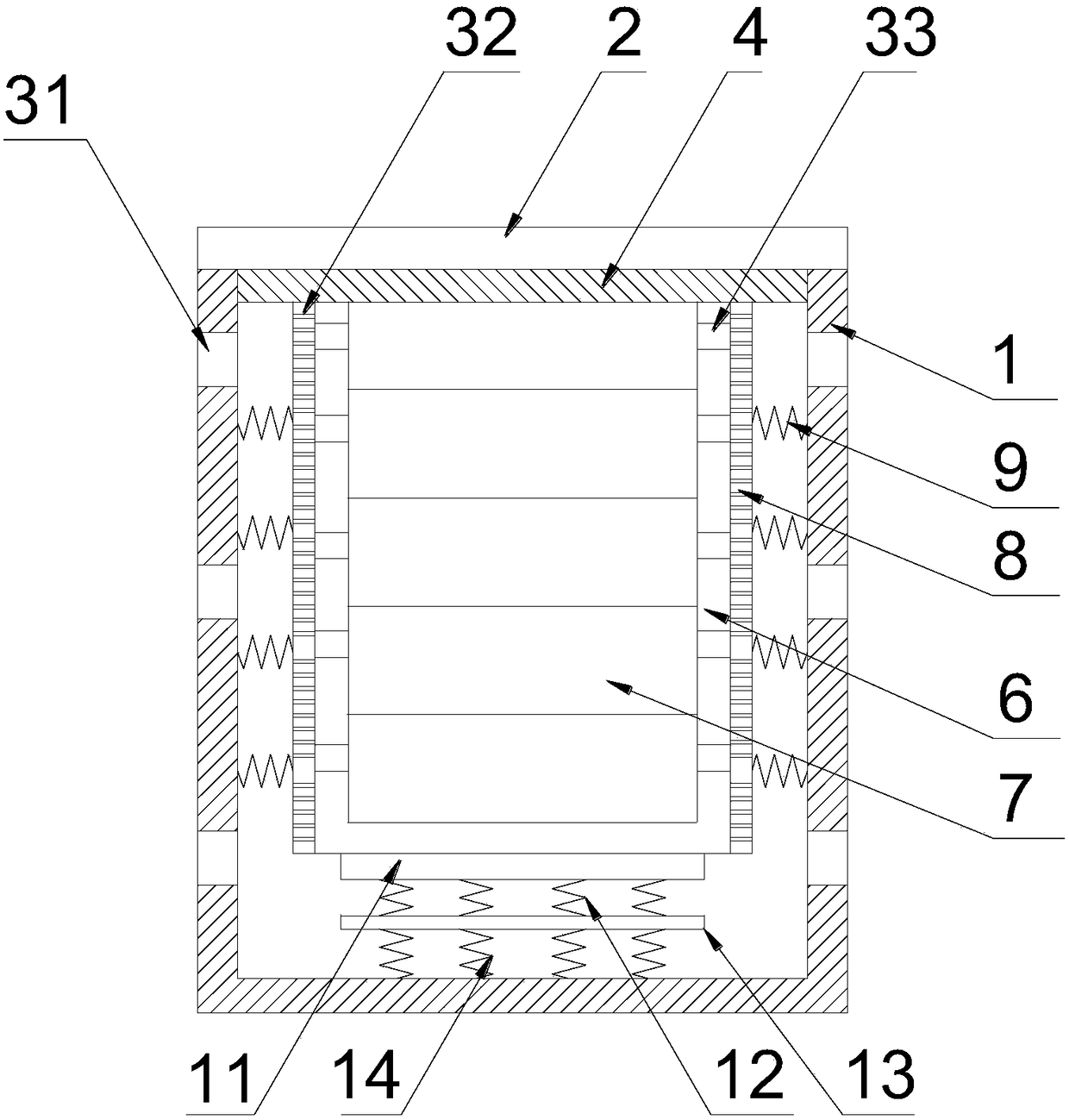

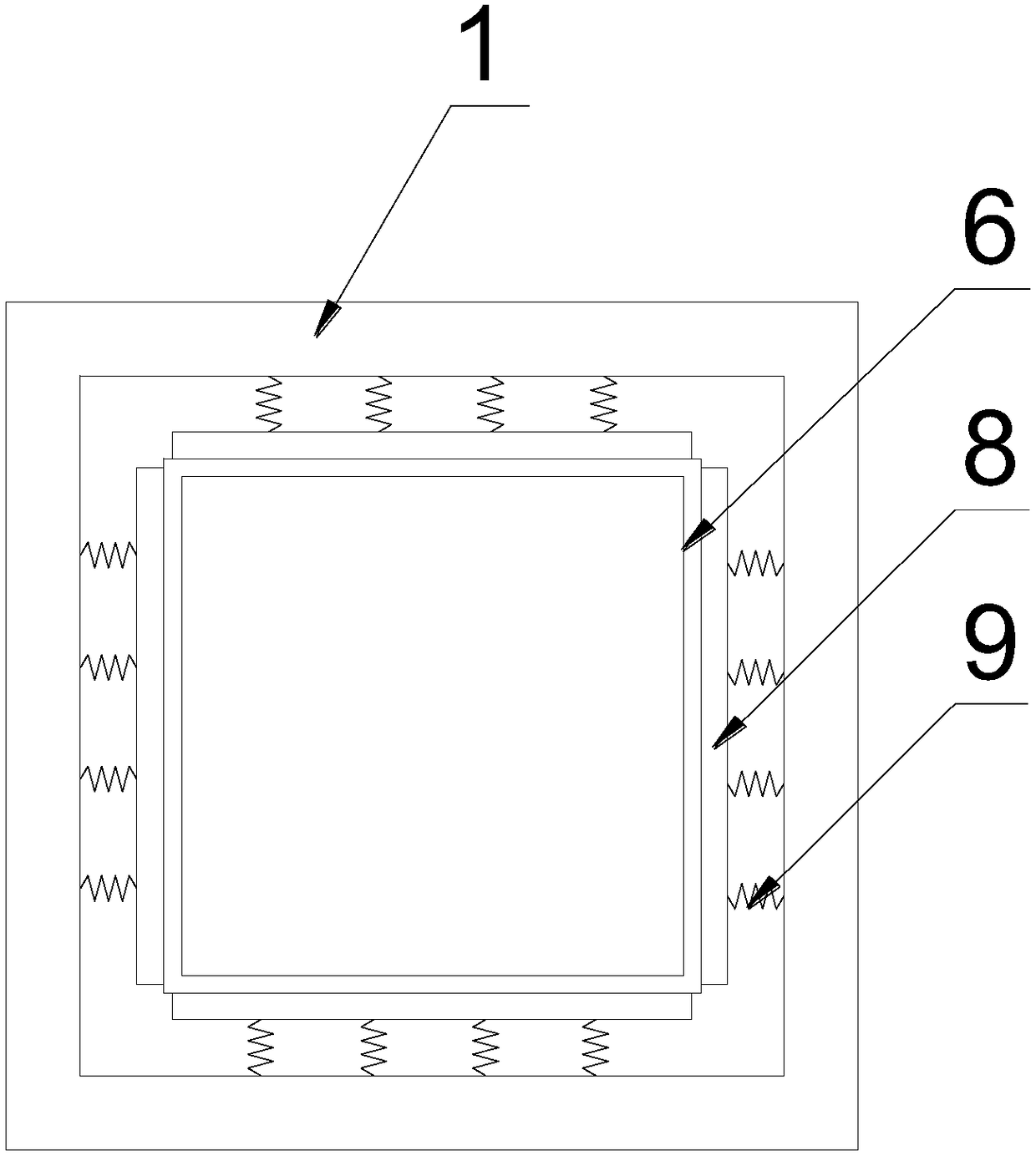

[0017] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of a ventilated transport box equipment assembly proposed by the present invention, figure 2 It is a schematic diagram of part of the structure of the air-permeable transport box equipment assembly proposed by the present invention.

[0018] refer to Figure 1-2 , a kind of air-permeable transport box equipment assembly that the present invention proposes, comprises outer box 1, box cover 2, inner box 6, transport box 7, baffle plate 8, spring 9, first bottom plate 11, first compression spring 12, second Base plate 13 and second compression spring 14;

[0019] The outer box 1 and the box cover 2 are set together, and the space between the outer box 1 and the box cover 2 is not sealed; the inner side of the box cover 2 is provided with a cushion 4; the inner box 6 is placed inside the outer box 1, and the inner box 6 is placed inside the transport box 7; A baffle plate 8 is arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com