Marine knuckle crane

A crane and marine technology, applied in cranes and other directions, can solve the problems of small load capacity, large space occupation, affecting work efficiency, etc., and achieve the effect of small bearing capacity requirements, small oil cylinder bearing capacity, and improved hull inclination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

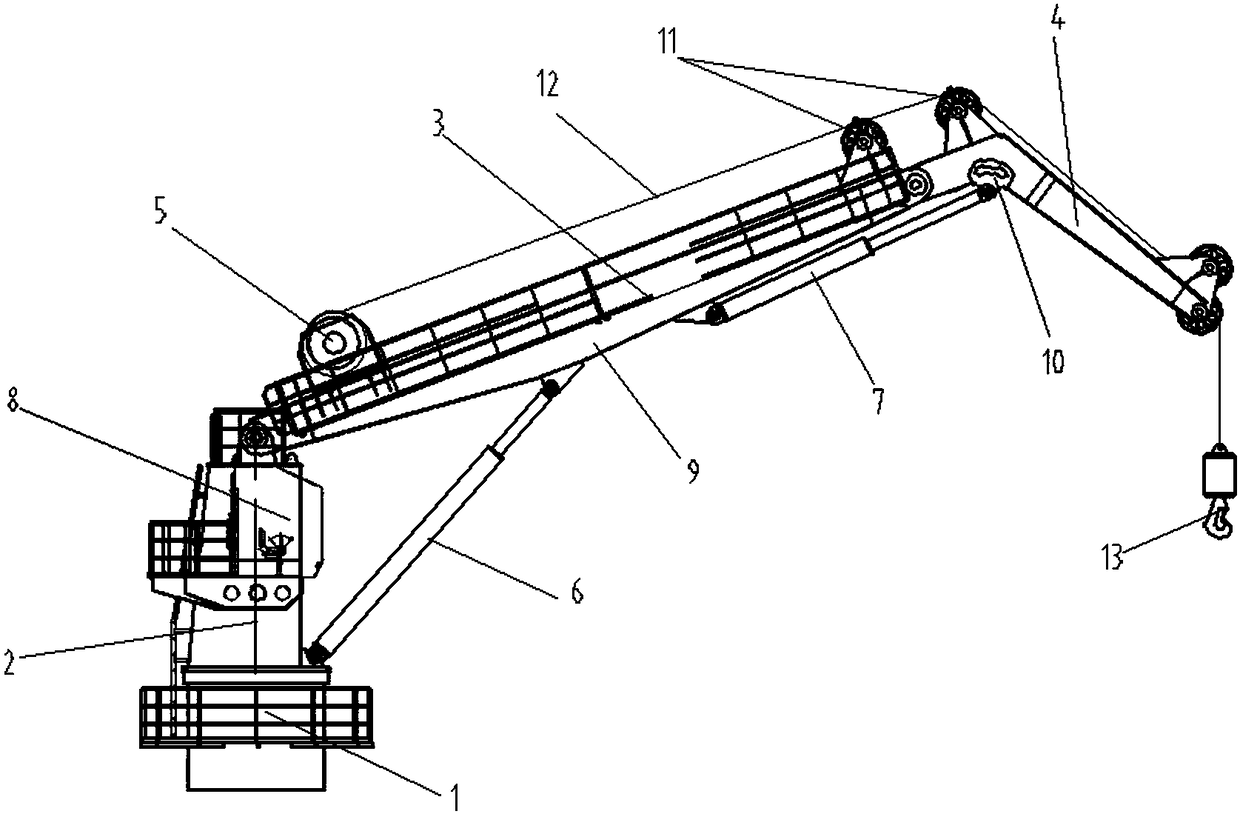

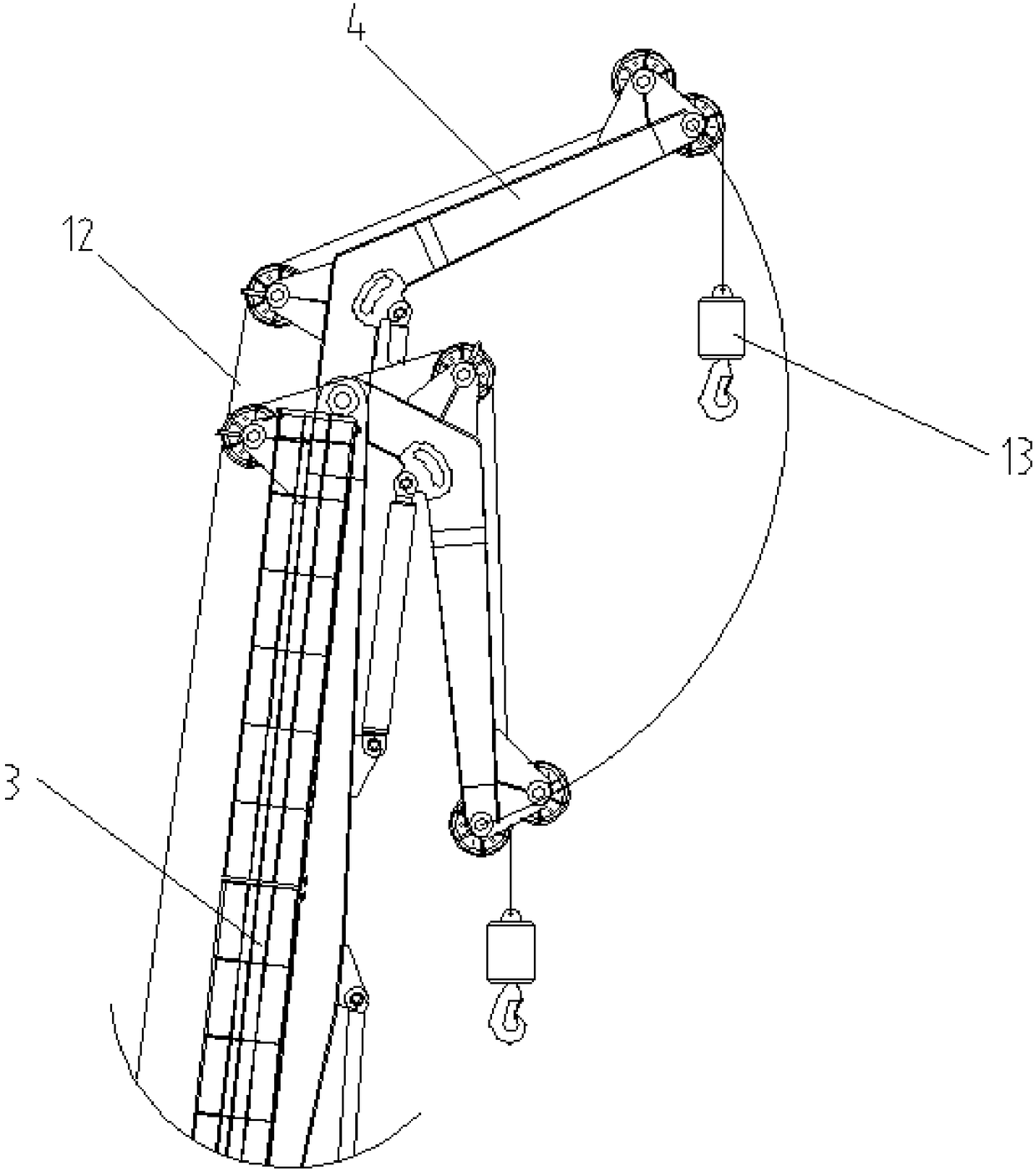

[0017] Such as Figure 1~2 As shown, a marine folding arm crane disclosed in the present invention includes a base 1, a tower body 2, a main boom 3, an auxiliary boom 4, a hoisting winch 5, a first oil cylinder 6 and a second oil cylinder 7, The base 1 is fixed on the side of the ship, and the tower body 2 is fixed on the base 1, and the front end of the tower body is provided with a cab 8, the main boom is hinged on the top of the tower body, and its bottom surface has a triangular mounting plate 9. The cylinder body end of the first oil cylinder 6 is hinged to the tower body below the cab, and the telescopic rod is hinged to the triangular vertex of the triangular plate. The first oil cylinder controls the folding of the main boom, and the auxiliary boom 4 is a folding The bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com