PLC firmware fuzz testing system and method based on stain analysis

A technology of fuzzy testing and taint analysis, applied in software testing/debugging, transmission systems, digital transmission systems, etc., can solve problems such as low test efficiency and inaccurate test cases, and achieve high test efficiency, high accuracy, and high targeting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

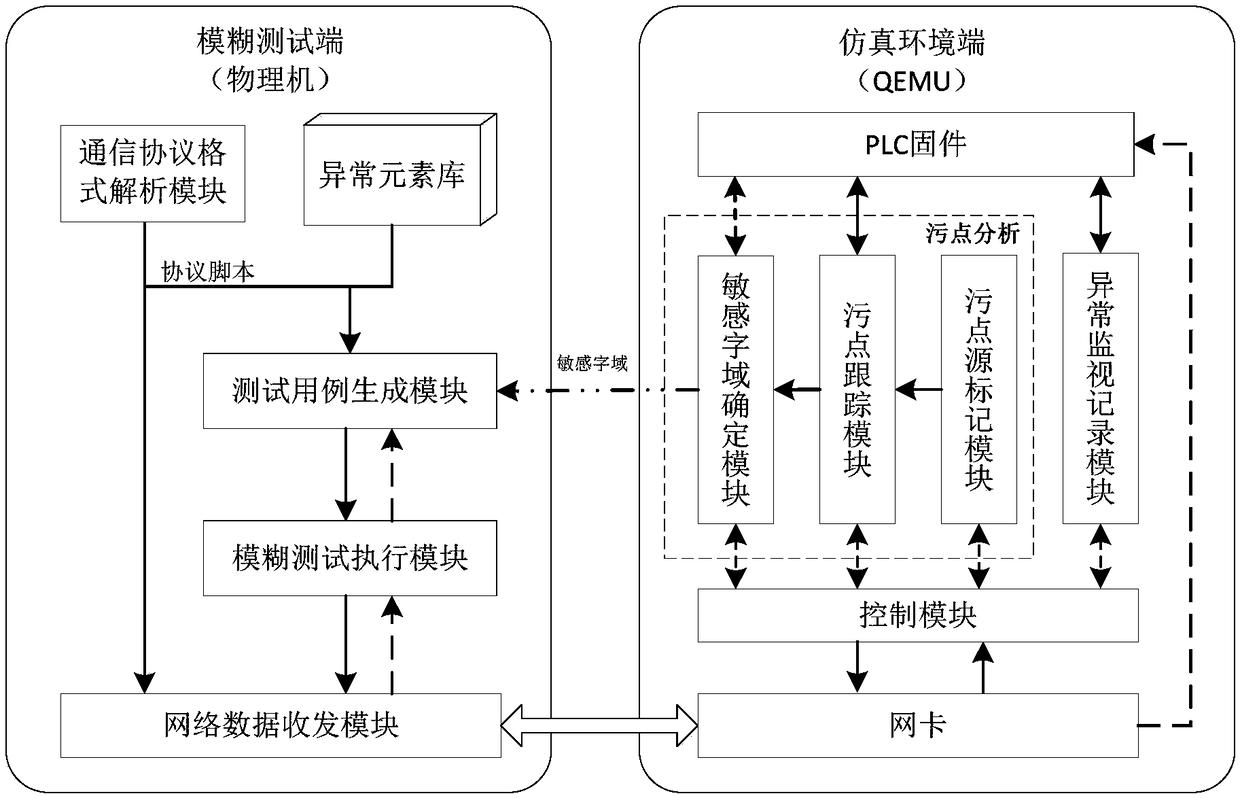

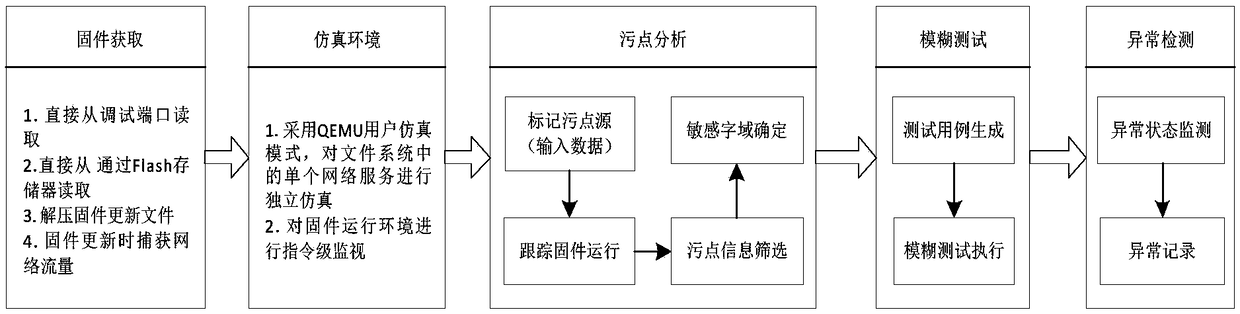

[0055] Embodiments of the present invention are as follows, with reference to figure 1 and figure 2 , a PLC firmware fuzz testing system based on taint analysis, including a simulation environment terminal and a fuzz testing terminal, the fuzz testing terminal can construct normal network data packets, and construct accurate The mutated fuzzy test case, and establishes a communication connection with the emulation environment end; the emulation environment end includes an emulation platform and a submodule built on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com