Water machine automatic in filter element popping and water way switching

A technology of automatic switching and automatic ejection, applied in the field of filter elements of water purifiers, can solve the problems of dirty environment, overflow of water machine, overflow of water from water machine, etc., and achieve the effect of solving the problem of alarm device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

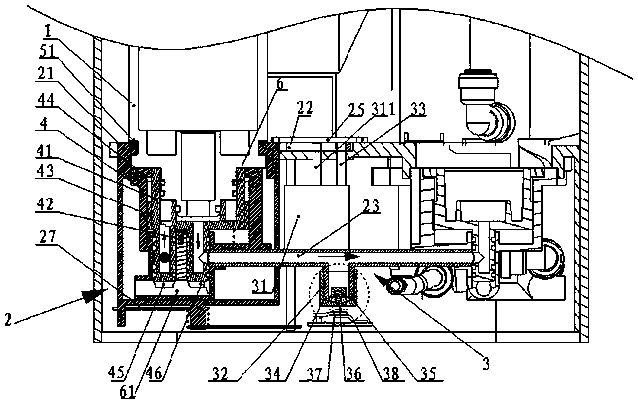

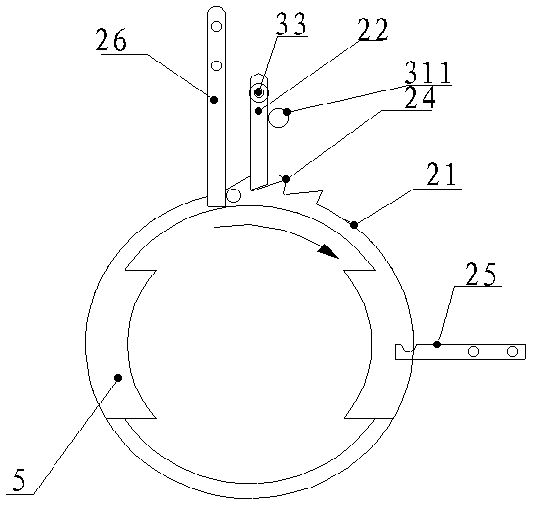

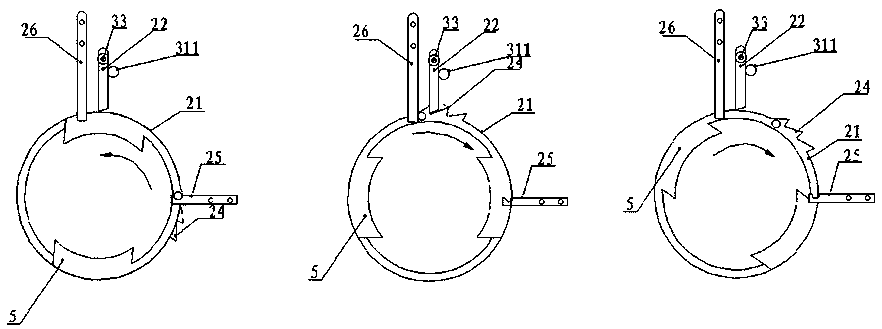

[0031] see Figure 1-7, a water machine that automatically ejects the filter element and automatically switches the waterway, including a filter element 1, a ratchet assembly 2 and a pressure assembly 3; the ratchet assembly 2 includes a ratchet seat 21 and a pawl 22; the ratchet seat 21 is sleeved with a filter element Base 4; the filter base 4 is provided with a movable slide 41; a first spring 42 is set between the bottom of the filter base 4 and the bottom of the movable slide 41; the bottom of the filter base 4 is provided with a water inlet 45 and an outlet The water tank 46; the water inlet tank 45 communicates with the bottom of the water outlet tank 46 through a channel 61; the side wall of the water inlet tank 45 is provided with a first water inlet hole 451; the side wall of the water outlet tank 46 is provided with a first water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com