Ratchet mechanism with staggered locking and releasing functions and ratchet wheel clamp

A ratchet mechanism and ratchet technology are applied in the field of ratchet clips and ratchet mechanisms, which can solve the problems of inconvenient and laborious release of ratchet clips, and achieve the effect of increasing the meshing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

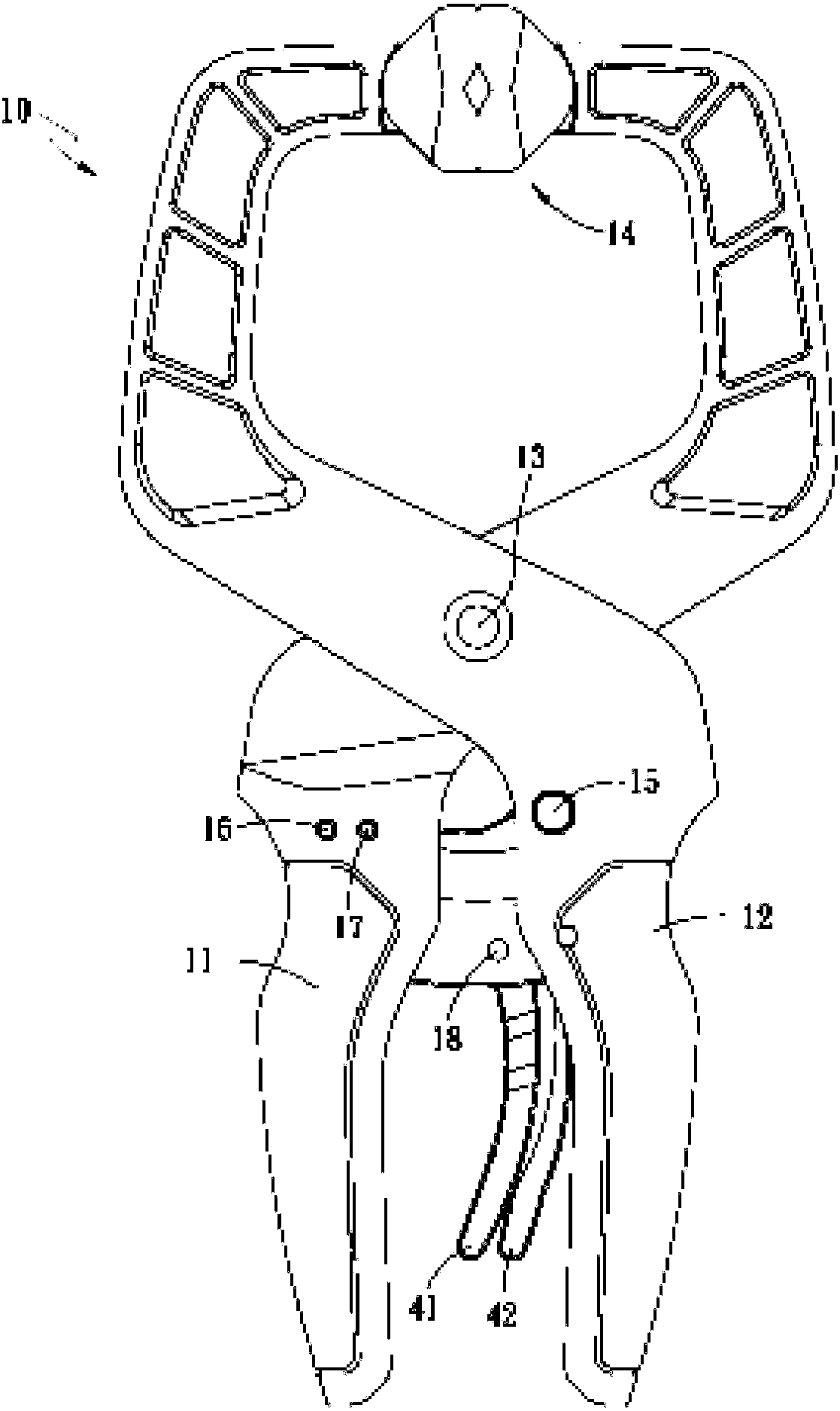

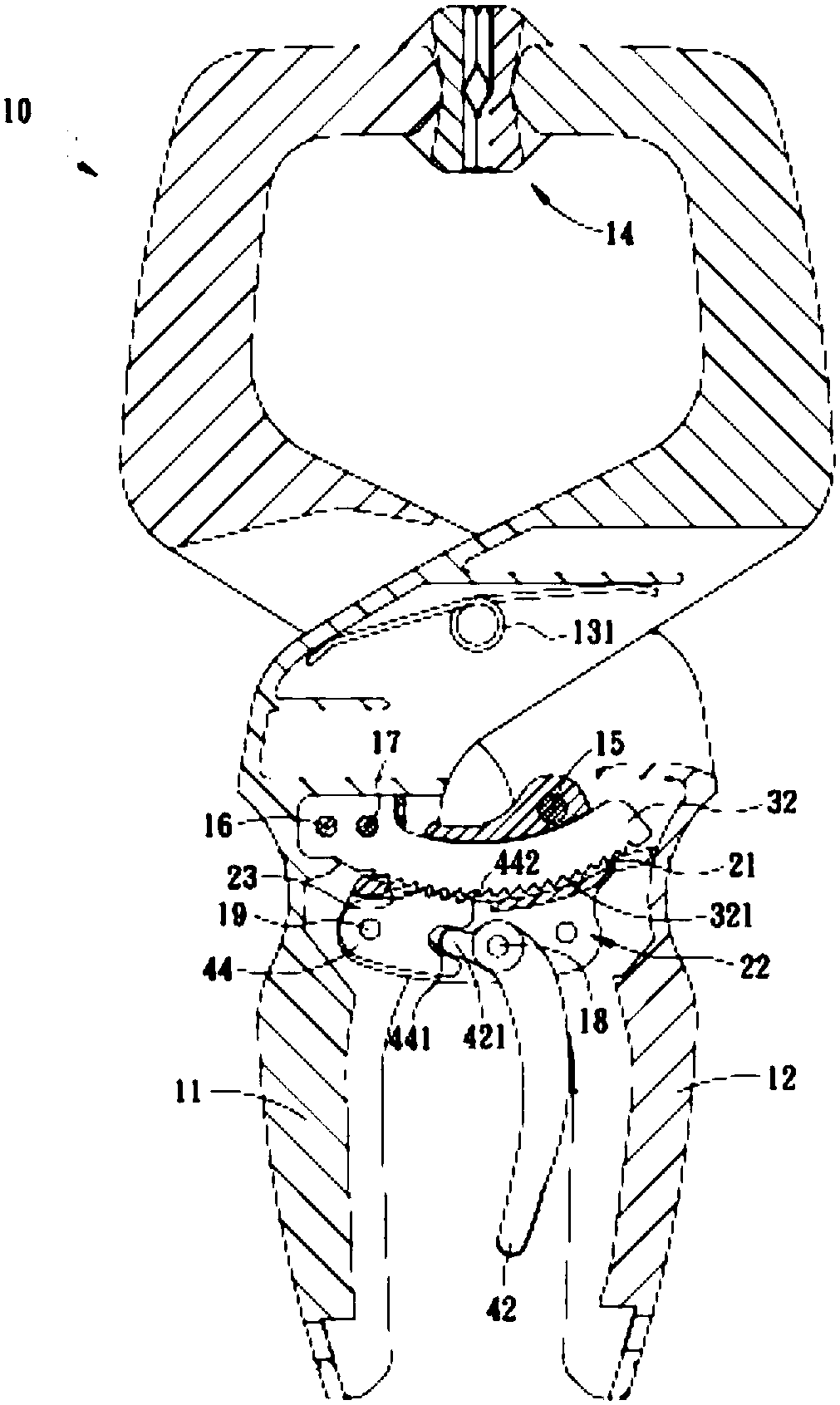

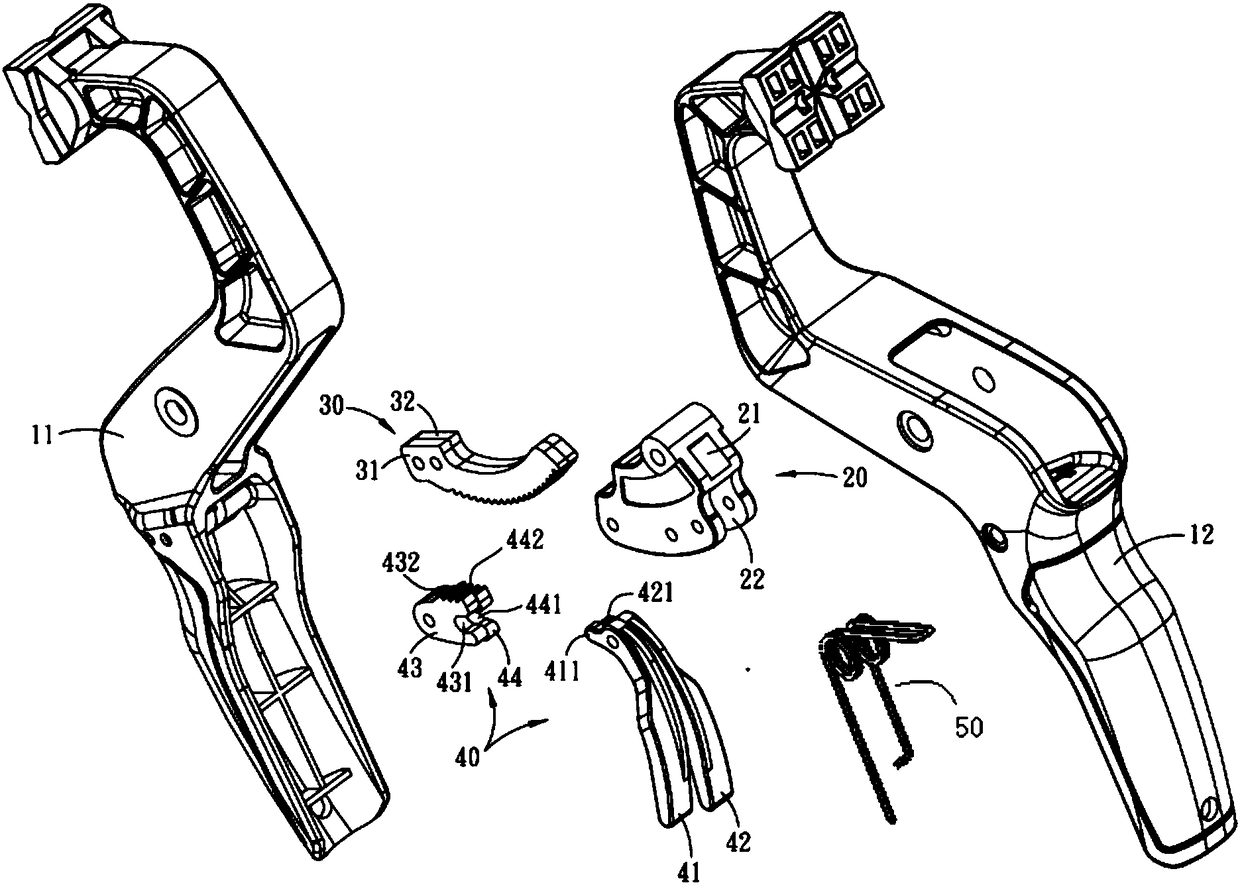

[0099] figure 1 and figure 2 It shows the configuration of the first embodiment of the ratchet clamp proposed by the present invention including the clamp mechanism and the ratchet mechanism. Wherein, the clamp mechanism 10 is connected with the first clamp arm 11 and the second clamp arm 12 through the connecting shaft 13, and the connecting sleeve is provided with a torsion spring 131, and the two ends of the torsion spring 131 are respectively pressed against the first clamp arm 11 and The second clamping arm 12 , and the first clamping arm 11 and the second clamping arm 12 control the opening or closing of the jaws 14 with the connecting shaft 13 as the rotation center. Specifically, when the first clamp arm 11 and the second clamp arm 12 are operated to be relatively close together, the jaw 14 can be gradually reduced, and the torsion spring 131 can be elastically deformed under force, and then the position of the jaw 14 can be fixed by the ratchet mechanism. , so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com