Hydraulic tensioning device for rubber track tensioning wheel

A technology of rubber crawler and tensioning device, which is applied to crawler vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of manual adjustment, the rubber crawler belt is easy to fall off, and the impact of the wheel train cannot be effectively alleviated. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A hydraulic tensioning device for a rubber track tensioning wheel of the present invention will be further described in detail below in conjunction with the accompanying drawings.

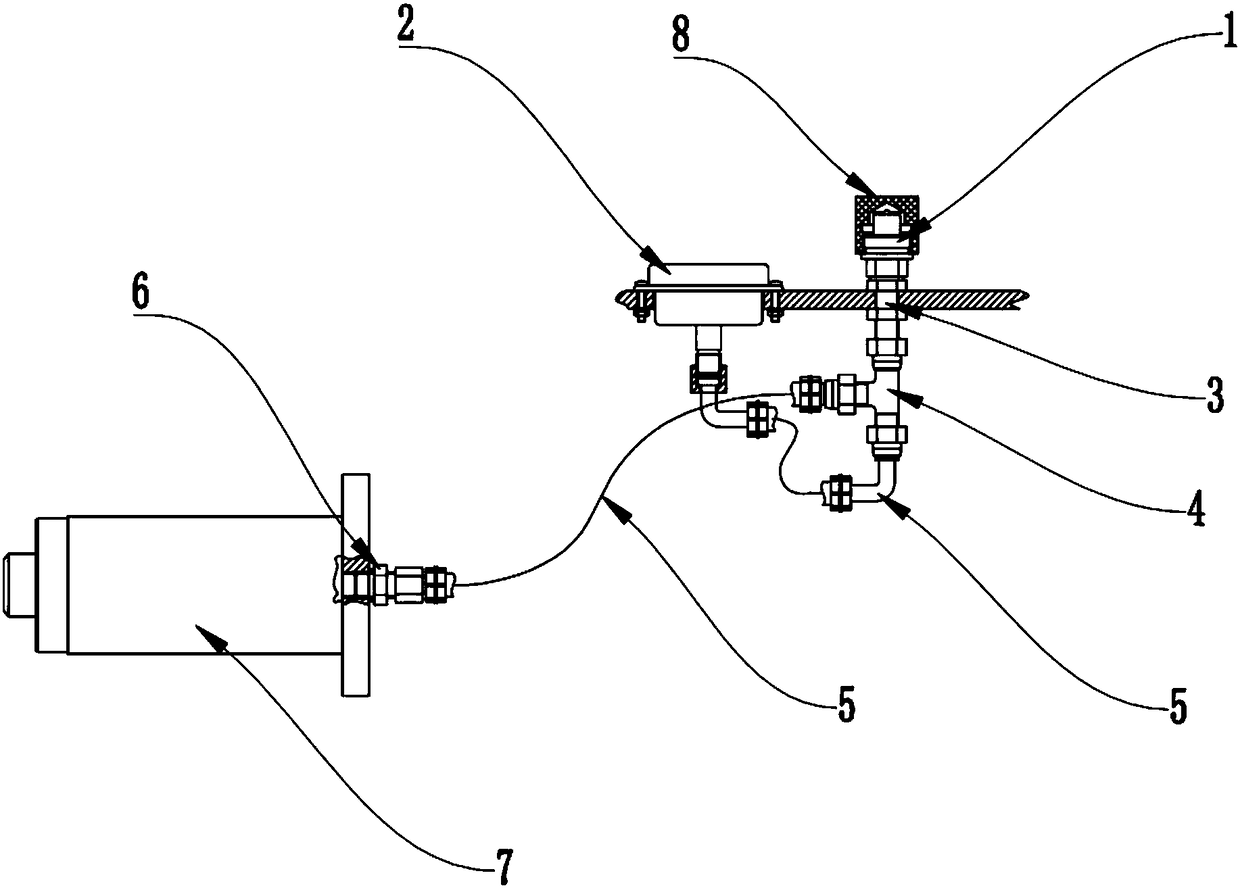

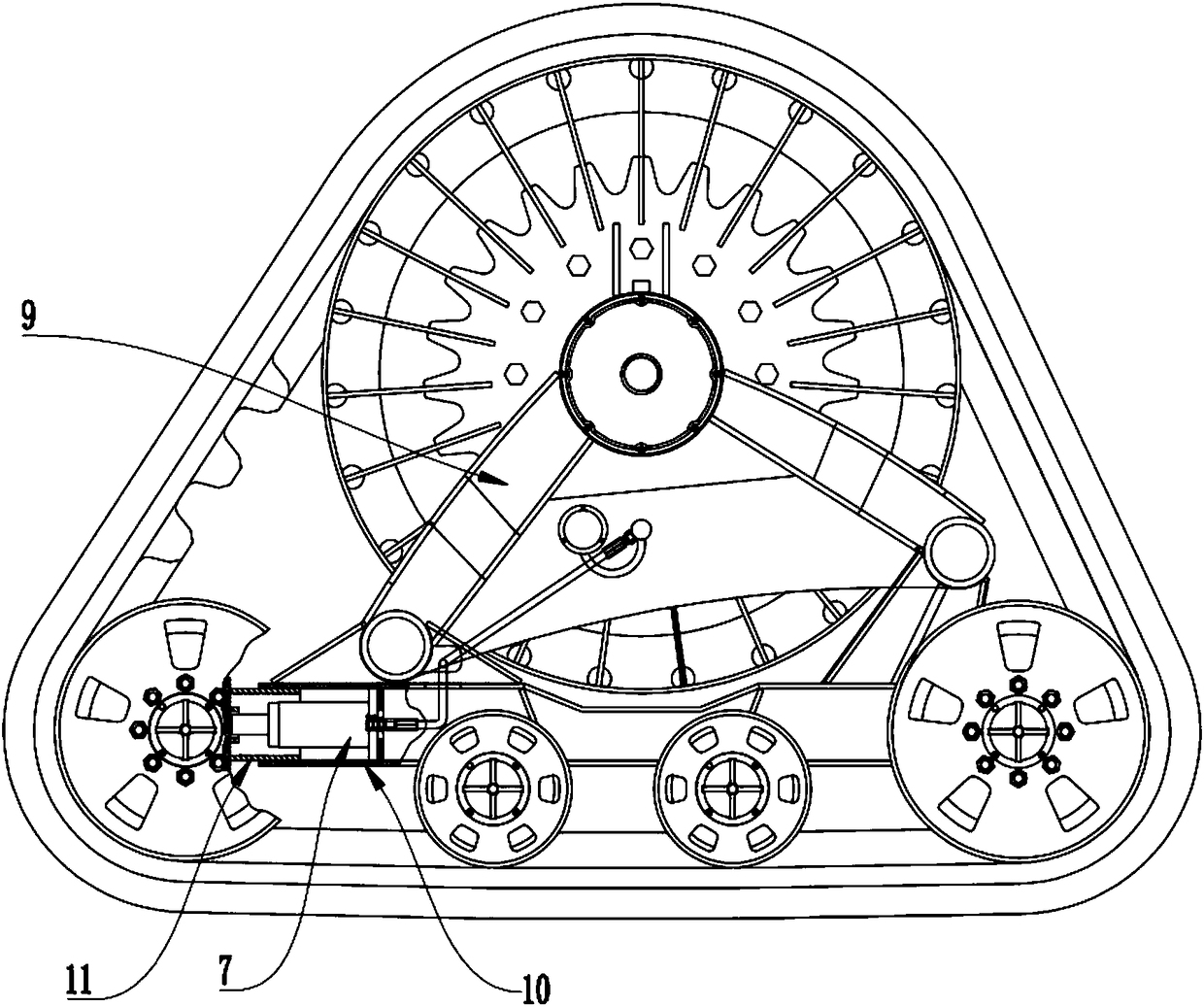

[0014] Combined with the accompanying drawings, a hydraulic tensioning device for a rubber track tensioning wheel, including an oil inlet pipe joint 1, a pressure gauge 2, a wall pipe joint 3, a tee pipe joint 4, a high pressure oil pipe 5, a joint body 6, and a tensioning oil cylinder 7 and nut 8.

[0015] It also includes a frame upper frame 9. The pressure gauge 2 and the oil inlet pipe joint 1 are installed on the outer plate of the frame body upper frame 9. The oil inlet pipe joint 1 passes through the wall pipe joint 3, the three-way pipe joint 4, the hydraulic rubber hose and the tensioner. Oil cylinder 7 is connected with pressure gauge 2.

[0016] Described oil inlet pipe joint 1 is the male joint of quick joint, has the function of one-way sealing, locks with nut 8 when not refuel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap